Acid Resistance Brick Used in Corrosion-Resisting Liner of Petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

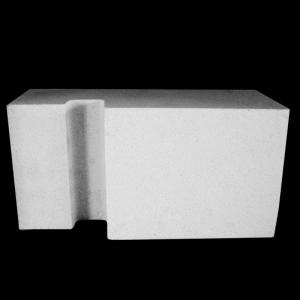

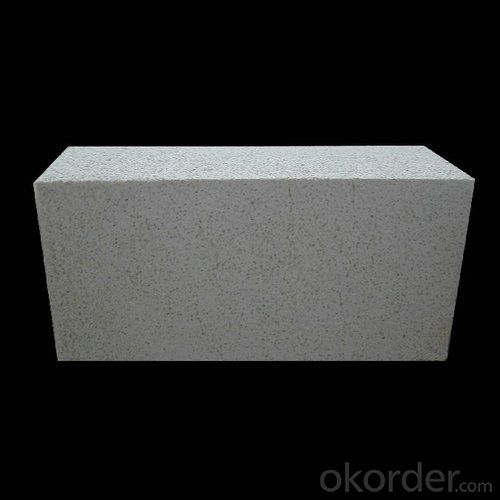

General Information of Acid Resistance Brick

CMAX acid resistance brick is specially used as lining in reaction tower of chemical plants, fertilizer factories and sulfuric acid industries or inside the corrosion-resistance pool and ditch.

Feature of Acid Resistance Brick

Strong acid and alkali resistance

Size available as customer’s requirement

Application of Acid Resistance Brick

Acid Resistance Brick is widely used in corrosion-resisting liner of petroleum, chemical industry, chemical fertilizer, food, chemical fiber, laboratory, pharmacy, papermaking, generate electricity, smelt, electroplating room, and the inner corrosion-resisting lining of tower, pool, pot, tank, etc. It is also used for sewage conduit and open-air floor.

Images of Acid Resistance Brick

Technical Data of Acid Resistance Brick

ACID RESISTANCE BRICK

Chemical Composition (%)

SiO2 68

Al2O3 25

Fe2O3 ≤2

CaO+MgO ≤2

Na2O+K2O ≤3

Bulk Density (g/cm3) ≥2.2

Water Content (%) 3-5

Cold Crushing Strength (Mpa) 85

Bending Strength (Mpa) ≥58.8

Acid Resistance (%) ≥99.8

Under Thermal Shock Resistance Testing No cracking

Water-absorptivity Average A 0.2%≤A≤0.5%

FAQ of Acid Resistance Brick

1. Who We Are?

CNBM is a Fortune 500 and a governmental owned National Building Material company in Beijing, China.

2. What We Can Do?

We can supply ALL KINDS OF REFRACTORIES and CERAMIC FIBER PRODUCTS in high quality and competitive price.

3. Who Our Customers Are

MORGAN THERMAL CERAMICS

ALLIED MINERAL

UNIFRAX

- Q:Acid resistant brick lining, engineering scaffolding, how to take?

- Construction preparation, familiar with drawings, specifications, technical disclosure, do a good job of the handover process.

- Q:Is acid proof brick alkali resistant?

- See, he made up, if it is relatively stable, but also a certain degree of alkaline resistance, of course, may be prone to caustic corrosion

- Q:How can acid proof cement be used?

- After drying to curing acidification, the basic method is to brush the surface of 40% sulfuric acid, once every 4 hours, every time the crystal precipitation should be removed in the next coating, until no crystallization, acid treatment after use.

- Q:What is anticorrosive floor tile?

- The above construction method is simple, and the normal paving tiles are the same. It is convenient to add 2-3mm cross micelles when leaving gaps.

- Q:Does the chimney have high acid resistance?

- The chimney particles and gases, mostly coal tar products, material acidic, therefore, take good acid resistance, acid proof brick, Grouts also used potassium silicate clay acid is preferred. If it is an ordinary high alumina brick, it does not meet the requirements of acid resistance, and only the chimney lined with acid resistant bricks.

- Q:Is there a construction picture for the acid proof brick in the pickle pond?

- Acid resistant brick, acid resistant ceramic tile in the shop, many users only pay attention to beauty, and use not leave seam shop, or shop too tight, too close, easy to leave hidden dangers for the future.

- Q:What is acidproof brick?

- The main component of acid resistant brick is silica, and Hao Ran acid resistant bricks are made of imported raw materials and imported color materials by high temperature firing.

- Q:What is acid proof brick

- Acid proof brick is made of quartz, feldspar, clay as the main raw material, made by high temperature oxidation corrosion resistant materials, resistant to high pH, low water absorption, is not easy to be oxidized at room temperature, the media can not easily be pollution performance, except hydrofluoric acid and hot phosphoric acid, the temperature of chlorine saline, hydrochloric acid, sulfuric acid and nitric acid and at room temperature in any concentration of alkali, corrosion resistance are excellent.

- Q:Do you want to leave the seam on the acid proof brick? What is the width of the seam?

- It is necessary to leave the seam when resisting the acid brick. Acid resistant bricks are corrosion resistant ceramic tiles, and all ceramic tiles have a certain expansion ratio, and there is a phenomenon of expansion and contraction.

- Q:What is acid proof tile, acidproof ceramic tile brand introduction?

- Acid resistant tile, each tile in production, have to do product testing

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Acid Resistance Brick Used in Corrosion-Resisting Liner of Petroleum

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords