All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

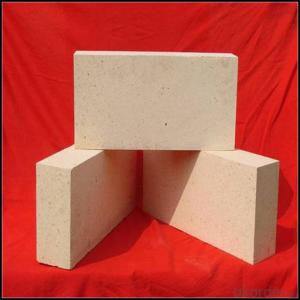

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Monolithic RefractoriesView More

Ceramic Fiber ProductsView More

Refractory BricksView More

Raw Materials For RefractoryView More

Q & A

How do refractory materials contribute to sustainable development?

Refractory materials contribute to sustainable development by extending the lifespan of high-temperature industrial processes, reducing energy consumption and greenhouse gas emissions. They improve the energy efficiency of furnaces and kilns, allowing for better heat retention and minimizing heat loss. This leads to reduced fuel consumption and lower carbon dioxide emissions. Additionally, refractory materials have a longer lifespan, reducing the frequency of replacements and minimizing waste generation. Overall, the use of refractory materials promotes sustainable practices in industries and helps in achieving environmental goals.

What are the advantages of using refractory coatings for electrical conductivity resistance?

Refractory coatings offer several advantages for electrical conductivity resistance. Firstly, these coatings provide excellent insulation properties, preventing the flow of electric current and reducing the risk of short circuits and electrical failures. Secondly, refractory coatings can withstand high temperatures, making them suitable for applications where heat is generated, such as in electrical motors or power transmission systems. Additionally, these coatings are chemically inert, providing resistance against corrosion, oxidation, and chemical reactions that could degrade the electrical conductivity of the surface. Overall, refractory coatings offer enhanced safety, thermal stability, and longevity, making them a valuable choice for maintaining electrical conductivity resistance.

What are the common refractory materials used in the chemical industry?

The common refractory materials used in the chemical industry include fire clay, silica, alumina, magnesia, and zirconia. These materials possess high heat resistance and can withstand harsh chemical environments, making them suitable for lining furnaces, reactors, and other equipment in chemical processing plants.

Wholesale Refractory Materials from supplier in Slovakia

Our team of experts is dedicated to understanding your specific requirements and providing tailored solutions that meet your needs. Whether you are in need of refractory bricks, castables, insulation materials, or any other refractory products, we have you covered. We work closely with our trusted suppliers to ensure that we only offer products of the highest quality, ensuring optimal performance and durability.

In addition to supplying refractory materials, we also offer a range of services to support your projects. Our sales team is available to provide you with detailed quotations, ensuring transparency and competitive pricing. We understand the importance of timely delivery, and our logistics team is committed to ensuring that your materials reach you on time and in perfect condition.

Furthermore, our technical support team is always ready to assist you with any technical queries or issues you may encounter. We have a deep understanding of the industry standards and regulations, and can provide guidance on the selection, installation, and maintenance of refractory materials.

As a subsidiary of CNBM, we have access to a global network of resources and expertise. This allows us to stay updated with the latest industry trends and innovations, ensuring that we can offer you the most advanced solutions for your projects.

We take pride in our commitment to customer satisfaction and strive to build long-term partnerships with our clients. Our goal is to become your trusted partner for all your refractory materials needs in Slovakia, providing you with exceptional products, services, and support. Contact us today to discuss your requirements and let us help you achieve success in your projects.

In addition to supplying refractory materials, we also offer a range of services to support your projects. Our sales team is available to provide you with detailed quotations, ensuring transparency and competitive pricing. We understand the importance of timely delivery, and our logistics team is committed to ensuring that your materials reach you on time and in perfect condition.

Furthermore, our technical support team is always ready to assist you with any technical queries or issues you may encounter. We have a deep understanding of the industry standards and regulations, and can provide guidance on the selection, installation, and maintenance of refractory materials.

As a subsidiary of CNBM, we have access to a global network of resources and expertise. This allows us to stay updated with the latest industry trends and innovations, ensuring that we can offer you the most advanced solutions for your projects.

We take pride in our commitment to customer satisfaction and strive to build long-term partnerships with our clients. Our goal is to become your trusted partner for all your refractory materials needs in Slovakia, providing you with exceptional products, services, and support. Contact us today to discuss your requirements and let us help you achieve success in your projects.

Hot Search

- Monolithic Refractories in Nicaragua

- Ceramic Fiber Products in Mauritius

- Refractory Bricks in Mozambique

- Raw Materials For Refractory in Venezuela

- Ceramic Fiber Products in Cambodia

- Ceramic Fiber Products in Vietnam

- Monolithic Refractories in Cyprus

- Monolithic Refractories in Burundi

- Monolithic Refractories in France

- Raw Materials For Refractory in Moldova