2016 Hot New Products Hydroponic Garden Greenhouse Propagation Root Heat Mat /Seed Cell Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

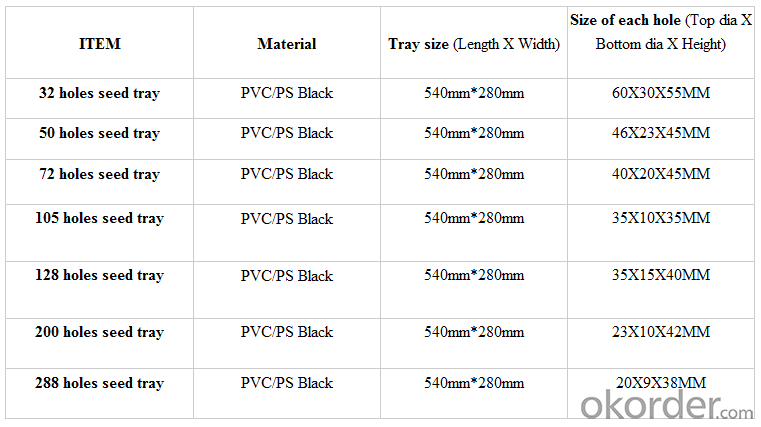

Specification of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Features of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

· Material: HIPS

· Thickness: 0.5mm-1.5mm, Standard:1mm

· Weight: 80g(±5)g-230g(±5)g, Standard weight:155g(±5)g

· Size: length:490mm-540mm, width:190mm-345mm,depth:25mm-150mm

· Standard:540mmX280mm

· Cell count: 18-512

· Package: In Carton

· Warrenty: 8-10 times

Packaging & Delivery

Packing Detail: export standard carton or large bags

Delivery time: 4 million per momth after receipt of deposit

Advantage:

Waterproof, UV-resistant, extrusion-resistant

Easy carry for young seeding plant and grow

Service:

1. Quick, efficient and professional response within 24 hours, 14 hours online services

2. 10 years manufacturing and exporting experience in agriculture field.

3. Technical support and solution by chief engineer.

4. Strict quality control system & team, high reputation in the market.

5. Full range of irrigation products for choice

6. OEM/ODM services

7. Accept sample order before Mass Order

Picture of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

FAQ of Plug Trays HIPS Made Plastic Plug Tray for Greenhouse (Growing and Seedling):

Q: 1.How long is the production time?

A: Usually one to two weeks.

Q: 2.How is the seed tray being packaged?

A: They can be packaged in carton or pallets. Carton size is 1375px*725px*1250px.

Q:3.How many times can the seed tray be used?

A: Under the same environment, it is decided by the thickness. Usually 0.6mm thickness can be used for 1 or 2 times.

1.0 thickness can be used for 3-4 times. 1.5 thickness can be used for 8-10 times.

- Q:Can using a plastic retainer in my freshly stretched ear lead to infection? i'm poor so the retainer i have in my ear is actually the shaft of a cotton bud is this okay? or am i just tempting fate?

- Plastic/acrylic is horrible for newly pierced/stretched piercings, also for long term use. It will emit toxins into your body, eventually making you sick while irritating the crap out a new piercing. I was cheap a few years ago and used plastic jewelry in my healed lobes. Within days they were red, swollen, itchy and crusty. I switched to real jewelry - stainless steel or titanium (I forget which) and within hours they were back to normal. Save up your money, and buy some actual good quality jewelry. Your ears will thank you for it.

- Q:What are some ground cover options for dry and arid climates?

- Some ground cover options for dry and arid climates include drought-tolerant plants like succulents, cacti, yucca, lavender, sage, thyme, and rosemary. Additionally, low-growing grasses such as buffalo grass and blue grama grass can also thrive in these conditions.

- Q:My cat always licks plastic, not any plastic, but plastic bags. He will do this for a long while at a time, 10 or 12 minutes. Is my cat retarted or what?

- MIne is obsessed with chewing on the plastic that holds a 6 pack of drinks together. Some cats just have a 'thing'.

- Q:How do you choose the right ground cover for a specific soil type or texture?

- To choose the right ground cover for a specific soil type or texture, it is important to consider the moisture retention, drainage, pH level, and nutrient content of the soil. Conducting a soil test can provide valuable information about these factors. Based on the results, research and identify ground covers that thrive in similar soil conditions. Additionally, consider the amount of sunlight the area receives and choose ground covers that are suitable for that level of light. Consulting with local garden centers or horticulturists can also provide useful guidance in selecting the appropriate ground cover for your specific soil type or texture.

- Q:How does agricultural plastic affect temperature and moisture control?

- Agricultural plastic can have both positive and negative effects on temperature and moisture control. On one hand, plastic mulch and greenhouse coverings can help increase soil temperature, which is beneficial for crop growth in cooler climates. The plastic also acts as a barrier, reducing evaporation and moisture loss from the soil, thus aiding in moisture control. However, agricultural plastic can also negatively impact temperature and moisture control. Improper use or disposal of plastic materials can lead to increased soil temperatures, resulting in overheating and reduced crop productivity. Additionally, the use of excessive plastic coverings can hinder natural air and water movement, leading to moisture buildup and potential fungal diseases. Therefore, it is crucial to employ plastic materials judiciously, ensuring proper installation, maintenance, and disposal practices to maximize the benefits and minimize the negative impacts on temperature and moisture control in agriculture.

- Q:How do agricultural plastic products help with pest exclusion?

- Agricultural plastic products help with pest exclusion by creating a physical barrier that prevents pests from accessing crops. These products, such as mulch films, greenhouse covers, and insect netting, effectively block insects, birds, and other pests from reaching the plants, reducing the risk of damage and crop loss.

- Q:Can ground cover plants be used in containers or hanging baskets?

- Yes, ground cover plants can definitely be used in containers or hanging baskets. While they are typically grown to cover large areas of the ground, they can also be a great choice for adding interest and texture to container gardens or hanging baskets. They can create a lush and trailing effect, spilling over the edges of the container. Plus, they are often low-maintenance and can tolerate a wide range of growing conditions, making them a versatile choice for container gardening.

- Q:does the plastic remain through the winter?

- Plastic mulch is not mulch. Mulch is something that helps the soil, plastic mulch type substances will not benefit your soil but they will help with weed protection. And yes you leave it there at the end of the season.

- Q:I usually use plastic tampons but sometimes i use cardboard. I was just wondering whats the difference and what kind do you use?

- I usually use plastic, but I'll use cardboard if it has that Silk film on it and has a rounded tip. As for the kind, it depends on my budget that month, sometimes store brand, sometimes kotex, always..doesn't matter too much as long as I have something.

- Q:What are some ground cover options for areas with alkaline soil?

- Some ground cover options for areas with alkaline soil include creeping juniper, Russian sage, lavender, yarrow, and sedum.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

2016 Hot New Products Hydroponic Garden Greenhouse Propagation Root Heat Mat /Seed Cell Plug Tray

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords