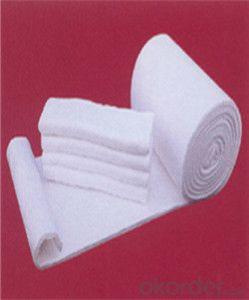

1260 NATI Ceramic Fiber Blanket for Stable Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 2000000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quality 1260 NATI Ceramic Fiber Blanket

Product Description:

Ceramic fiber is made from high quality clay, high purity alumina and silica oxides by spun or blown process. Ceramic fiber has a range of products: ordinary type, standard form, high-purity type, high-alumina type and containing zirconium type. Different types of products use different materials. The performance of ceramic fiber is also different, and they are suitable for different working temperatures.

Ceramic fiber can be used after optional cutting. When storing ceramic fiber, pay attention to moisture. The high-alumina type and containing zirconium type products can be directly used as furnace linings.

Product Features:

• Low thermal conductivity

• High tensile strength

• Resilient to thermal shock

• Corrosion resistance

Product Applications:

• Petrochemical process heater refractory fiber lining

• General furnace backup insulation

• Heat treating furnace or intermittent(shuttle) kiln hot face lining

• Electrical insulator

• Heat seals for kiln car or furnace door

• High temperature acoustic

• Fire protection

Product Specifications:

Product Packing:

Plastic bag in a carton box

Product Images:

Produce Processing

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered by OKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: What other products does OKorder offer?

A3: We offer a full range of refractory bricks, mortar, cement, ceramic fiber products, and more.

Q4: Where are Ceramic Fiber products used?

A4: Ceramic fiber products have many advantages, including: high temperature stability, lightweight, superior insulation, and ease of application. Fiber products are available in a variety of product forms to solve a range of thermal management application problems across various industries. The main industrial market segments that use ceramic fiber and soluble fiber products are the aluminum, iron, steel, heat treatment, power, incineration, boilers, and glass industries.

Q5: What kind of Ceramic Fiber should I use?

A5: When selecting the fiber type for a particular application, it is important to consider all factors. If the fiber/fabric will not have to support a load at temperature, the lower-cost industrial grade fibers may be appropriate. However, if the fiber will be load bearing at temperature as in ceramic matrix composites, then one of the composite grade fibers would be a better choice. Of course there may be other factors, such as corrosion, chemical resistance, or atmospheric conditions that may require trade-off in the selection process.

- Q:One that could be used as a meal substituteAnd do you need to add yogurt or milk to the smoothie? Could I just use water and ice or something? I have juices here, but they're grapefruit and cranberry and I don't like either of them much (my parents bought them to mix and use in special drinks at Christmas.)

- Have your Sim relax on the bed and then ask the other one to joinThen if they like each other enough when you click on the other one it will give you the option to cuddle, make out, or woohoo.

- Q:what is the best insulation that i can use for my attic?

- You shouldn't use it until you can get a trained repairman to look at itA lift (elevator) can be incredibly dangerous if malfunctioning.

- Q:Its the model with the top hatch opening, but the thing is on this kiln that I discovered in the art room is that the door does not securely closeIs there a reason/way to attach the top hatch door? Please help, the owners manual is not giving me any headway.

- NoGrossU Health FreakJ/PEveryone Has Different Tastes]

- Q:hi,i want to try felting a knitted piece, but all i have read so far about felting suggests wool and i have used 100% acrylic yarn uld acrylic be feltedgt;thanks

- No, acrylic will not feltYou must use animal fiber to feltSome blends will felt, but the majority of the content must be animal fiberTypically 85% wool content or higher (not superwash) will feltFelting is fun, you can pick up some basic merino wool for around 5 or 6 bucks at Michaels or your local yarn shop.

- Q:Hey, I'm in bed and my comforter is like static or somethingIt's making sparks and I'm scared it will electrocute me!!! Please help, thanks

- LOL! It's static electricity from the cold airMy micro-fiber fleece blanket does the same thingA bunch of little white sparks fly when I adjust the coversDon't worry about it.

- Q:herbal medecine for diabetes that is accessible to everyone.

- Cool Entertainment Centers

- Q:Insulating my attic - any good ideas from experienced people?

- I have a better question: Why the fk do you care what I think about your musical taste? Seriously, caring what an idiot like me thinks of your musical taste is totally not rock rollEven though I also like some of the stuff you like (Maiden, Mozart, Tallica, whatever), it doesn't fkin' matter what I thinkYou like what you like, and you like it because you like itThat's what rock roll is all aboutI went to a Beethoven / Bach recital wearing leather pants and a smelly denim cutoff over a ripped tee shirt, and the next month I wore a business suit (tie and jacket) to see Judas Priest and Slayer as the opening actWhy? Because that's what I wanted to listen to and that's what I happened to feel like wearing at the time, and anybody who said you can't do that was proven wrong the minute they said itRock roll isn't a mode of dress or a style of music, it's being who you are and not having to explain it to anyone.

- Q:Ok so i want to be a cheer leader for halloween and i was wondering how you make pom-pomsWhat are some other good accesories that would be good with a cheerleader outfit? so far i have-my moms old letterman jacket-im going to wear my hair in high pigtails and put a bow in it

- You need to look in the phone book under governement agencies and call your state housing boardThey can tell you and you can report this horrible landlordHope your cooler soon!

- Q:Silly question, but is it okay for a cat to play with yarn? I know that they can get tangled up in it so I only let her play with it while I'm with herBut are there fibers or ingredients to the yarn that can be harmful?Thanks for your information.

- You can use tea, coffee, plants, nut shells, berries, beets, etcto make natural dyesThe general directions for using natural dyes is linked belowBasically, you brew your chosen ingredient, soak the item, check the color, soak more if needed, rinse then dryThe second link also includes a list of materials their resulting colors.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

1260 NATI Ceramic Fiber Blanket for Stable Quality

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 roll

- Supply Capability:

- 2000000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products