Underground Spiral Welded Corrugated Galvanized Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Underground Spiral Welded Corrugated Galvanized Steel Pipe for Mining

Press grade: Maximum PN -0.097MPa

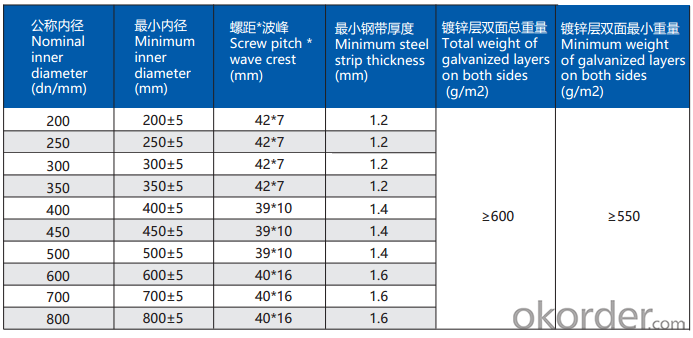

Size: DN200MM-DN800MM

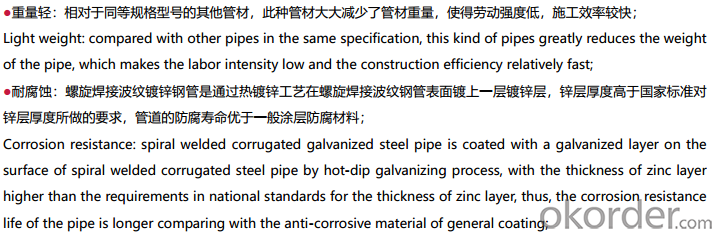

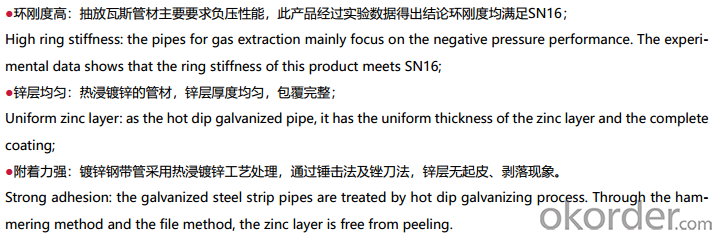

Features:

Specification

We own three industry bases for manufacturing pipes, fittings and new materials, including the biggest production line of steel wire reinforced PE composite pipe in the world, and top advanced PE pipe production line.

We get long term cooperation with leading material suppliers in the world and professionally provide the pipeline system solutions of matched products and technical cases by the whole industry chain from materials R&D to pipeline engineering installation.

- Q:Can steel pipes be used for transporting drinking water?

- Indeed, steel pipes have the capacity to transport drinking water. These pipes are extensively employed in water distribution networks and have a long history of usage. Renowned for their robustness, potency, and ability to resist corrosion, steel pipes are highly favored. Nonetheless, it is imperative to ensure that steel pipes designated for drinking water transportation are adequately coated or lined in order to avert any potential contamination originating from the metal. Moreover, it is crucial to conduct routine inspections and maintenance to safeguard the pipes' integrity and to forestall any leaks or ruptures that could jeopardize the water's quality.

- Q:What is the difference between seamless steel pipes and seamless stainless steel pipes?

- The main difference between seamless steel pipes and seamless stainless steel pipes lies in their composition. Seamless steel pipes are typically made from carbon steel, which is an alloy of iron and carbon. On the other hand, seamless stainless steel pipes are made from an alloy of iron, carbon, and chromium, which gives them enhanced corrosion resistance and durability. This makes seamless stainless steel pipes suitable for applications where resistance to corrosion is essential, such as in the food industry or in environments with high humidity or exposure to chemicals.

- Q:What are the different types of coatings applied to steel pipes?

- There are several types of coatings that can be applied to steel pipes, including epoxy, polyethylene, fusion bonded epoxy (FBE), and zinc coatings. These coatings provide protection against corrosion, abrasion, and chemical damage, ensuring the longevity and durability of the steel pipes in various applications.

- Q:How do you calculate the pipe head loss for steel pipes?

- The Darcy-Weisbach equation is utilized for calculating the pipe head loss in steel pipes. This equation establishes a connection between the head loss (hL) and various factors such as the flow rate (Q), pipe diameter (D), pipe length (L), fluid density (ρ), fluid velocity (V), and the friction factor (f). The formula can be expressed as: hL = (f * (L/D) * (V^2))/(2g) Where: - The head loss (hL) is measured in meters - The friction factor (f) is dimensionless - The pipe length (L) is measured in meters - The pipe diameter (D) is measured in meters - The fluid velocity (V) is measured in meters per second - The acceleration due to gravity (g) is typically taken as 9.81 m/s^2 The friction factor (f) relies on the Reynolds number (Re) of the flow, which is a dimensionless quantity representing the ratio of inertial forces to viscous forces. The Reynolds number can be calculated using the following equation: Re = (ρ * V * D) / μ Where: - The Reynolds number (Re) is dimensionless - The fluid density (ρ) is measured in kg/m^3 - The fluid velocity (V) is measured in meters per second - The pipe diameter (D) is measured in meters - The dynamic viscosity of the fluid (μ) is measured in Pa·s or N·s/m^2 The friction factor (f) can be obtained from empirical correlations or from Moody's diagram, which establishes a connection between the Reynolds number, the relative roughness of the pipe surface, and the friction factor. By substituting the calculated friction factor (f) and other known values into the Darcy-Weisbach equation, the head loss in the steel pipe can be determined. It is important to note that the head loss represents the energy lost due to friction and other factors and is usually expressed in terms of pressure drop or height difference.

- Q:Is hot dipped plastic pipe steel?

- Hot dip plastic composite pipes used in coal mine gas drainage, ventilation system, fire water system, central air conditioning HVAC piping circulating water, industrial water supply and drainage, water supply and drainage life, conveying gas and other gases, power threading, chemical pipelines and water disposal pipe etc..

- Q:How are steel pipes used in the manufacturing of chemical processing equipment?

- Steel pipes are commonly used in the manufacturing of chemical processing equipment due to their durability, corrosion resistance, and ability to withstand high temperatures and pressures. These pipes are used to transport fluids, such as chemicals, gases, and liquids, throughout the various stages of the manufacturing process. In chemical processing equipment, steel pipes are primarily used for two main purposes: as conduits for the transportation of raw materials and as channels for the distribution of processed products. Firstly, steel pipes are used to transport raw materials, such as chemicals and solvents, from storage tanks or external sources to the various processing units within the equipment. These pipes ensure the safe and efficient movement of these materials, allowing for accurate and controlled dosage and distribution. Steel pipes are preferred due to their strength, which enables them to handle the high pressures and temperatures involved in chemical processing. Secondly, steel pipes are used to distribute the processed products throughout the equipment. Once the raw materials have undergone various chemical reactions and transformations, the resulting products need to be transported to the next stage or collected for further processing. Steel pipes are ideal for this purpose as they can withstand the corrosive nature of many chemicals and can handle the high temperatures encountered during these processes. Furthermore, steel pipes are also used in chemical processing equipment for their versatility and compatibility with various chemicals and solvents. They can be easily customized to accommodate specific requirements, such as different pipe sizes, shapes, and fittings. This flexibility allows for efficient design and installation, ensuring a seamless flow of materials and products throughout the equipment. Overall, steel pipes play a crucial role in the manufacturing of chemical processing equipment by providing a reliable and efficient means of transporting raw materials and distributing processed products. Their durability, corrosion resistance, and ability to withstand high temperatures and pressures make them an essential component in ensuring the safe and efficient operation of chemical processing equipment.

- Q:Can steel pipes be insulated for thermal efficiency?

- Steel pipes can indeed be insulated to enhance their thermal efficiency. By insulating steel pipes, heat loss or gain can be minimized, depending on the specific purpose. Typically, the insulation material is wrapped around the pipes, creating a protective barrier. This barrier effectively prevents heat transfer between the pipes and the surrounding environment. As a result, the energy required to heat or cool the fluid flowing through the pipes is significantly reduced, leading to improved energy efficiency. This practice is widely employed in industries such as HVAC, oil and gas, and industrial processes, where precise temperature control is crucial. Moreover, insulation also serves to prevent condensation and corrosion on the outer surface of the pipes. All in all, insulating steel pipes is a cost-effective measure that enhances thermal efficiency and reduces energy consumption.

- Q:Can steel pipes be used for underground water supply networks?

- Yes, steel pipes can be used for underground water supply networks. Steel pipes are commonly used for underground water supply networks due to their durability, strength, and resistance to corrosion. They can withstand high pressure and are able to handle the weight of the soil and other external forces. Additionally, steel pipes are available in various sizes and can be easily welded, making them suitable for different water supply system requirements. However, it is important to take into consideration factors such as the quality of the soil, the presence of chemicals or corrosive substances, and the need for regular maintenance to ensure the longevity and efficiency of the steel pipes in underground water supply networks.

- Q:How are steel pipes protected against ultraviolet radiation?

- Steel pipes are typically protected against ultraviolet radiation by applying a coating or paint that contains UV-resistant additives. This coating acts as a barrier, preventing the harmful effects of UV radiation from causing damage or degradation to the steel surface.

- Q:What is the impact toughness of steel pipes?

- The ability of steel pipes to withstand sudden or high-velocity impacts without fracturing or breaking is referred to as their impact toughness. This property measures the material's resistance to cracking when subjected to dynamic loading conditions. The impact toughness of steel pipes is highly significant as it determines their capacity to endure accidental impacts or external forces during transportation, installation, and operation. To evaluate the impact toughness of steel pipes, standardized tests such as the Charpy V-notch test or the Izod test are commonly utilized. These tests involve striking a notched sample of the steel pipe with a pendulum or a falling weight and measuring the amount of energy absorbed by the material until it fractures. The impact toughness is then calculated based on this energy absorption. A high impact toughness is desirable in steel pipes as it signifies a greater ability to absorb energy and resist fracture, making them more resilient to sudden impacts or loading conditions. This characteristic is particularly crucial in applications where steel pipes are exposed to high-stress environments, such as in oil and gas pipelines, automotive components, or structural applications. Several factors can influence the impact toughness of steel pipes, including their chemical composition, heat treatment, and microstructure. For instance, alloying elements like manganese, chromium, and nickel can enhance the impact toughness by promoting the formation of fine-grained microstructures and preventing crack propagation. Similarly, appropriate heat treatment processes like quenching and tempering can optimize the material's microstructure and mechanical properties, thereby improving its impact toughness. In conclusion, the impact toughness of steel pipes is a vital property that determines their ability to withstand sudden or high-velocity impacts. It is evaluated through standardized tests and can be influenced by factors such as chemical composition, heat treatment, and microstructure. A high impact toughness is desirable in steel pipes to ensure their structural integrity and resistance to fracture when subjected to dynamic loading conditions.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Underground Spiral Welded Corrugated Galvanized Steel Pipe for Mining

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m

- Supply Capability:

- 10000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords