Steel-Plastic composite Geogrid for coal mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of CNBM

China National Building Materials (Group) Corporation (CNBM) is a state-owned enterprise in charge of administrative affairs in China building materials industry. Established in 1984, CNBM is a large group corporation of building materials with total assets of RMB 25 billion and a total staff of 30,000. Now CNBM owns more than 200 subsidiaries in and abroad the country, including wholly-owned corporations and joint ventures.

FAQ of geosynthetics :

What is geosynthetics ?

Geosynthetics form a perfect erosion control fabric used extremely widely in civil engineering to stabilize and reinforce slopes and soil under or next to roads, railways, dams, water reservoirs etc.. They can be easily applied which minimizes the time of construction, as well as they limit the resources and materials necessary.

What kinds of geosynthetics we have ?

Non-woven geotextile, geogrids, geocells, GCL, Geomembranes, Geonets, Geocomposites etc .

What is the geosynthetics used for ?

Hydraulic

Lagooning and Water Treatment, Ornamental Ponds, Golf Courses

Aquaculture and Desalination,Water Lagoons,Tanks, Reservoirs, Liquid Waste,Floating Cover Solutions, Drainage and Filtration

Environment

Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers

Civil Works

Erosion Control,Secondary Containment,Tunnels,Linear and Surface Works,Consolidation of Margins,Soil Reinforcement,Soil Separation.

Building - Parkings,Roofing,Soundproofing

Structure of Steel-Plastic composite Geogrid for coal mine description :

Made of polypropylene and steel wire by extension technology after inflaming retarding and anti static treatment , it can bear high tensile strength .This material has considerable tensile strength in longitudinal and lateral directions. This chain structure can effectively bear and diffuse forces on soil and is applicable to large area permanent load bearing foundation as a reinforce.

Features of Steel-Plastic composite Geogrid for coal mine:

Homogenous structure, low creepage ,anti-aging and resisting acid and alkaline.

Inflaming retarding , anti static ,long lifetime,high safety factor ,high bearing capacity

Application of of Steel-Plastic composite Geogrid for coal mine :

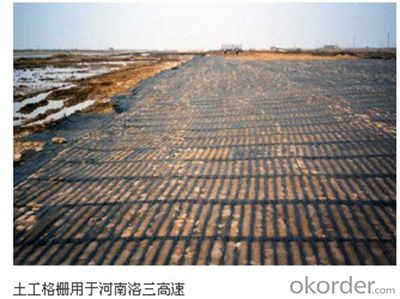

Make reinforce treatment for various of soft soil foundation to evenly distribute load stress and reduce unevensettlement , it is easy to wash coal . used in highway ,railway,port,airport, municipacl and projects of supporting in the recovery working face of coal mined and ladeway in the coal mine .

Specification of Steel-Plastic composite Geogrid for coal mine

Single mesh belt pulling strength not less than 4000N

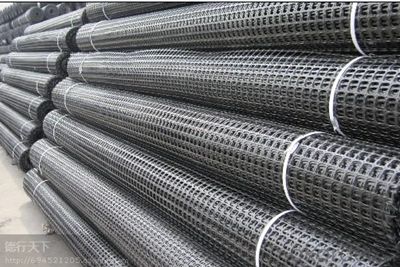

Width : 1M,2M,3M,4M.

Length: 50m,100,

Color: black

Packaging & Delivery of Steel-Plastic composite Geogrid for coal mine Each roll is wrapped in a woven bag then into container Or Packed as customers' requests.

Production periods of Steel-Plastic composite Geogrid for coal mine : within 10 days after receiving the deposit

- Q:Can geogrids be used in coastal erosion control projects?

- Yes, geogrids can be used in coastal erosion control projects. Geogrids are commonly used to stabilize soil and prevent erosion by providing reinforcement and structural support. In coastal areas, where erosion is a significant issue, geogrids can help to stabilize slopes, retain soil, and protect coastal infrastructure from the impact of waves and tides.

- Q:What are the installation guidelines for geogrids?

- The installation guidelines for geogrids typically include steps such as preparing the subgrade, ensuring proper compaction, rolling out the geogrid, anchoring it securely, and overlapping or connecting multiple rolls as necessary. It is important to follow the manufacturer's instructions and consult with an engineer or specialist to ensure correct installation and maximize the effectiveness of the geogrids.

- Q:Can geogrids be used in shoreline protection?

- Yes, geogrids can be used in shoreline protection. Geogrids are commonly used in coastal engineering projects to stabilize and reinforce the shoreline. They provide strength and stability to the soil, preventing erosion and protecting the shoreline from wave action and water currents.

- Q:And specification.. Thank you for answering me

- In order to achieve an asymmetric competitive advantage, now the problem of engineering design is really big, institutional problems

- Q:Are geogrids suitable for use in temporary retaining walls?

- Yes, geogrids are suitable for use in temporary retaining walls. Geogrids are commonly used in these applications due to their high tensile strength and ability to reinforce the soil behind the wall. They provide stability and prevent soil erosion, making them an effective solution for temporary retaining walls.

- Q:Can geogrids be used in soil stabilization for agriculture?

- Yes, geogrids can be used in soil stabilization for agriculture. Geogrids are commonly used in various soil stabilization applications, including agriculture, to improve soil strength, prevent erosion, and enhance load-bearing capacity. They help in stabilizing the soil by providing reinforcement and distributing loads, which is essential for promoting healthy crop growth and preventing soil erosion in agricultural lands.

- Q:What is the difference between a uniaxial and a biaxial geogrid?

- A uniaxial geogrid is designed to provide strength and stabilization in one primary direction, typically in the longitudinal direction. On the other hand, a biaxial geogrid is capable of providing strength and stabilization in two perpendicular directions, both in the longitudinal and transverse directions.

- Q:Do geogrids affect groundwater flow?

- Yes, geogrids can affect groundwater flow. Geogrids are often used in construction and civil engineering projects to stabilize soil and prevent erosion. They can create a barrier that restricts the movement of water, altering the natural flow of groundwater. However, the extent of this impact depends on the specific design and installation of the geogrids, as well as the local geological conditions.

- Q:How do geogrids improve the performance of geotextile tubes?

- Geogrids improve the performance of geotextile tubes by providing additional structural support, enhancing stability, and increasing tensile strength. They help to prevent stretching and deformation of the geotextile material, thereby maintaining the shape and integrity of the tubes. This reinforcement helps to withstand the forces exerted by water, soil, and other external factors, making geotextile tubes more durable and effective in applications such as erosion control, shoreline protection, and environmental containment.

- Q:What are the load-bearing capacities of geogrids?

- The load-bearing capacities of geogrids vary depending on factors such as the type and quality of the geogrid, the soil conditions, and the specific application. Geogrid manufacturers typically provide technical data sheets specifying the load-bearing capacities of their products, which can range from a few kilonewtons to several hundred kilonewtons per meter. It is important to consult these specifications and conduct appropriate engineering analysis to determine the suitable geogrid and its load-bearing capacity for a particular project.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Steel-Plastic composite Geogrid for coal mine

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 88 m²

- Supply Capability:

- 1800000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords