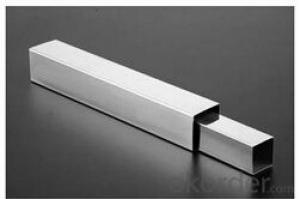

Stainless welded square steel pipe 9.5x15mm~63x133mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Name: Stainless welded square steel tube and pipe

1) Material: Stainless steel

2)Standards:300series

3) Shape:square pipe

4) Type: stainless steel square pipe

5) Surface: Pickling, Sand, Polished

6) Sizes range: 9.5x15mm~63x133mm

7) Wall thickness:0.5m~3.0mm

8)Packing:Export sea worthy package

9) Payment:T/T 30%payment in advance, 70% T/T before shipment or by L/C

10) Delivery:Within30days after receiving 30%T/T of deposit or L/C

Name | Stainless welded square steel tube and pipe |

Standard: | 300series |

Type | stainless steel square pipe |

Material | Stainless steel |

Shape | square pipe |

Sizes range | 9.5x15mm~63x133mm |

Wall thickness | 0.5m~3.0mm |

surface finish | Pickling, Sand, Polished |

Packing: | Export sea worthy package |

Delivery: | Within 30days after receiving 30%T/T of deposit or L/C |

MOQ: | 1Metric Ton/Metric Tons |

Price terms: | FOB, CFR, CIF |

Payment terms: | T/T, L/C |

Application | Stainless Steel square Pipe applies to Petroleum & chemical industries, construction field, machinery and hardware fields, food processing and medical industry, high or low temperature resistant, electricity industries, etc. |

Quality control: | a)Mill Test Certificate is supplied with shipment. b)Third party inspection is highly welcomed. |

Advantage | a) Strong processing and warehousing service b) Stock available c) Strict quality control |

- Q:Can stainless steel pipes be coated?

- Stainless steel pipes have the capability to undergo coating procedures. Coating these pipes serves multiple purposes, such as bolstering their durability, preventing corrosion, providing insulation, and enhancing their aesthetics. There exist diverse options for coating stainless steel pipes, including epoxy coatings, polyurethane coatings, and fusion-bonded epoxy coatings. These coatings are applied to the surface of the stainless steel pipes using various techniques, such as spraying, dipping, or electrophoretic deposition. The selection of the appropriate coating relies on the specific requirements of the application and the environment in which the pipes will be utilized. By coating stainless steel pipes, their lifespan can be significantly extended and their performance can be improved, making them suitable for a wide range of industries including oil and gas, chemical, water treatment, and construction.

- Q:How do you protect stainless steel pipes from heat damage?

- There are several steps one can take to safeguard stainless steel pipes against heat damage. 1. Insulate the pipes by wrapping them with high-temperature insulation materials like fiberglass or mineral wool. This insulation acts as a barrier, preventing excessive heat from reaching the pipes. 2. Apply heat-resistant coatings to the pipes. These coatings are specifically designed to withstand high temperatures and provide an extra layer of protection. 3. Ensure proper ventilation around the pipes to dissipate heat. Good ventilation helps in maintaining lower temperatures and reduces the risk of heat damage. 4. Install heat shields or guards around the pipes, especially in areas where there is a high risk of heat exposure. These shields can be made of materials like stainless steel or ceramic, which can endure high temperatures and act as a physical barrier between the pipes and the heat source. 5. Ensure proper installation of the pipes with appropriate clearances from heat sources. This prevents direct contact with extremely hot surfaces and reduces the risk of heat damage. 6. Regularly inspect the pipes to detect any signs of heat damage or deterioration. Address any issues promptly to prevent further damage. By implementing these measures, one can effectively safeguard stainless steel pipes from heat damage and prolong their lifespan.

- Q:Are stainless steel pipes suitable for wastewater treatment facilities?

- Stainless steel pipes are a great fit for wastewater treatment facilities due to their exceptional corrosion resistance. This quality makes them perfect for managing highly corrosive wastewater. Their ability to resist chemicals and acids prevents deterioration, minimizing the chances of leaks and contamination. Moreover, stainless steel pipes are hygienic and effortless to clean, which is vital in maintaining cleanliness at wastewater treatment facilities. Furthermore, their high strength-to-weight ratio enables easy installation and reduces the necessity for extra support structures. Hence, stainless steel pipes are a dependable and long-lasting option for wastewater treatment facilities.

- Q:What are the common sizes of stainless steel pipes used in construction?

- The common sizes of stainless steel pipes used in construction typically range from 1/2 inch to 12 inches in diameter.

- Q:What is the difference between 316 and 316L stainless steel pipes?

- The carbon content is the main distinguishing factor between 316 and 316L stainless steel pipes. Both alloys contain equal amounts of chromium, nickel, and molybdenum, which contribute to their corrosion resistance. However, 316L stainless steel pipes have a lower carbon content than 316 stainless steel pipes. The reduced carbon content in 316L stainless steel pipes helps prevent carbide precipitation during welding or high-temperature applications. This phenomenon, known as sensitization, can result in intergranular corrosion, compromising the overall corrosion resistance of the material. By reducing the carbon content, 316L stainless steel pipes are less prone to sensitization, making them more suitable for welding applications. Moreover, the lower carbon content in 316L stainless steel pipes enhances their resistance to corrosion in environments with high chloride exposure, such as coastal areas or industrial settings. This characteristic makes 316L stainless steel pipes the preferred choice in various industries, including marine, chemical, and pharmaceutical, where corrosion resistance is essential. To summarize, while both 316 and 316L stainless steel pipes offer excellent corrosion resistance, the lower carbon content of 316L stainless steel pipes improves weldability and resistance to sensitization. Therefore, 316L stainless steel pipes are commonly selected for applications involving welding or exposure to corrosive environments.

- Q:Can stainless steel pipes be used for swimming pool installations?

- Yes, stainless steel pipes can be used for swimming pool installations. Stainless steel is highly resistant to corrosion and can withstand the harsh chemicals used in pool water. It is also durable, long-lasting, and can handle high water pressure.

- Q:Can stainless steel pipes be used for HVAC systems?

- Yes, stainless steel pipes can be used for HVAC (Heating, Ventilation, and Air Conditioning) systems. Stainless steel is a widely used material in HVAC applications due to its durability, corrosion resistance, and high heat resistance. Stainless steel pipes are able to withstand high temperatures and pressures, making them suitable for both heating and cooling systems. Additionally, stainless steel pipes do not rust or corrode easily, which ensures a longer lifespan and minimal maintenance requirements for HVAC systems. The smooth interior surface of stainless steel pipes also allows for better airflow, which improves the efficiency of the HVAC system. Overall, stainless steel pipes are a reliable and efficient choice for HVAC installations.

- Q:Are stainless steel pipes resistant to sea water corrosion?

- Yes, stainless steel pipes are highly resistant to sea water corrosion due to their inherent properties such as chromium content that forms a protective film on the surface, preventing corrosion and ensuring durability in marine environments.

- Q:How are stainless steel pipes measured?

- Two main parameters are used to measure stainless steel pipes: outer diameter (OD) and wall thickness. The outer diameter corresponds to the pipe's outer circumference, while the wall thickness indicates the thickness of the pipe's walls. These measurements are crucial for determining the pipe's suitability for a particular application and ensuring compatibility with fittings and connectors. Stainless steel pipe dimensions are typically stated in millimeters or inches, and they may vary depending on project requirements or industry standards. Precise measurement is essential to guarantee the correct fitting and functionality of stainless steel pipes in diverse applications, including plumbing, construction, or industrial processes.

- Q:What is the difference between seamless and HFW stainless steel pipes?

- Seamless and HFW (High Frequency Welded) stainless steel pipes differ in their manufacturing process and the presence of a welded seam. Seamless stainless steel pipes are produced by piercing a solid billet or ingot and then rolling it into a cylindrical shape. This process eliminates the need for any welding, resulting in a pipe without any seams or joints. The absence of a welded seam enhances the overall strength and integrity of the pipe, making it ideal for high-pressure applications. On the other hand, HFW stainless steel pipes are created by using high-frequency electric resistance welding. In this process, a flat strip of stainless steel is passed through a series of rollers and then welded longitudinally using a high-frequency current. The welded seam is then heat-treated to ensure the same corrosion resistance as the base material. HFW pipes are generally more cost-effective compared to seamless pipes, making them a popular choice for various applications. While both seamless and HFW stainless steel pipes offer excellent corrosion resistance and durability, seamless pipes are often preferred in critical applications where high strength and reliability are crucial. The absence of a welded seam minimizes the risk of leakage and failure, making them suitable for industries such as oil and gas, petrochemical, and nuclear power. HFW stainless steel pipes, on the other hand, are more commonly used in less demanding applications such as water supply, plumbing, and construction. They provide a cost-effective solution without compromising the overall performance and corrosion resistance. In summary, the main difference between seamless and HFW stainless steel pipes lies in their manufacturing process and the presence of a welded seam. Seamless pipes are produced without any welding, offering superior strength and reliability for critical applications. HFW pipes, on the other hand, are manufactured through high-frequency electric resistance welding and are more cost-effective, making them suitable for less demanding applications.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Stainless welded square steel pipe 9.5x15mm~63x133mm

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 5000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords