hot rolled seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

stainless steel pipe

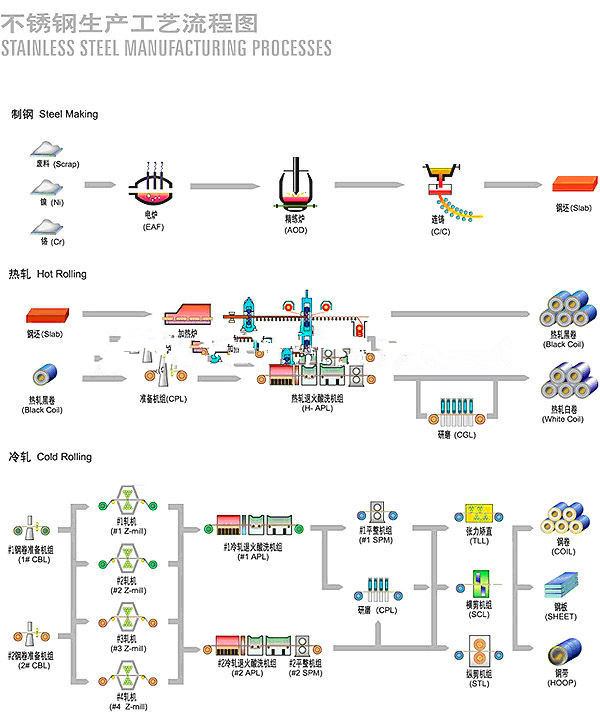

Stainless steel is a production which not easy rust,acid resistance and corrosion resistance,so it is widely used in light industry,heavy industry,daily necessities and the decoration industry.my company long term supply stainless steel porducts including:stainless steel sheet,stainless steel coil and stainless steel tube

Specifications

1.Specification:88.9*5.49 mm or others

2.Surface: NO.1

3.Length:6m or as your requirement

A series of photos

A series of pictures

- Q:Can stainless steel pipes be used in drinking water systems?

- Indeed, stainless steel pipes are suitable for utilization in drinking water systems. Being a material highly resistant to corrosion and possessing exceptional durability, stainless steel can endure the harsh elements found in water systems. It does not release any detrimental substances into the water, thus rendering it a secure option for drinking water purposes. Furthermore, stainless steel pipes are effortless to cleanse and uphold, effectively guaranteeing the quality and safety of the drinking water.

- Q:What are the common applications for stainless steel pipes?

- Stainless steel pipes have a wide range of applications due to their unique properties and versatility. Some of the common applications for stainless steel pipes include: 1. Plumbing and water supply systems: Stainless steel pipes are commonly used in plumbing and water supply systems due to their corrosion resistance and ability to withstand high pressure. They provide a reliable and long-lasting solution for transporting water and other fluids. 2. Oil and gas industry: Stainless steel pipes are extensively used in the oil and gas industry for transporting oil, gas, and other hydrocarbons. They can withstand high temperatures and pressures, making them suitable for exploration, production, and transportation of these resources. 3. Food and beverage industry: Stainless steel pipes are widely used in the food and beverage industry due to their hygienic properties and resistance to corrosion. They are commonly used for transporting liquids, such as milk, juices, and processed foods, ensuring the safety and quality of the products. 4. Chemical and pharmaceutical industry: Stainless steel pipes are highly resistant to corrosion, making them ideal for the chemical and pharmaceutical industry. They are used for transporting various chemicals, acids, and solvents, ensuring the integrity of the substances being transported. 5. Construction and architecture: Stainless steel pipes are used in construction and architectural applications due to their aesthetic appeal and structural strength. They are often used for handrails, balustrades, structural columns, and decorative applications, adding a modern and sleek look to buildings. 6. Automotive industry: Stainless steel pipes are utilized in the automotive industry for exhaust systems due to their heat resistance and durability. They can withstand high temperatures and corrosive gases, ensuring the efficient operation of the exhaust system. 7. Power generation: Stainless steel pipes are used in power plants for transporting steam, water, and other fluids. They are resistant to high temperatures and pressures, making them suitable for power generation applications. 8. Aerospace industry: Stainless steel pipes are utilized in the aerospace industry for various applications, including aircraft exhaust systems, hydraulic systems, and fuel lines. They offer high strength-to-weight ratio, corrosion resistance, and reliability, meeting the stringent requirements of the aerospace industry. In summary, stainless steel pipes find applications in various industries due to their corrosion resistance, durability, and versatility. They are used in plumbing, oil and gas, food and beverage, chemical and pharmaceutical, construction, automotive, power generation, and aerospace industries, among others.

- Q:Can stainless steel pipes be insulated with polyphthalamide?

- Polyphthalamide cannot be directly used to insulate stainless steel pipes. Usually, polyphthalamide is utilized as a high-performance thermoplastic for injection molding applications, rather than as insulation for pipes. For insulating stainless steel pipes, commonly used materials include fiberglass, mineral wool, and foam insulation. These materials are designed to provide thermal insulation, prevent heat transfer, and offer protection against corrosion and condensation. If there is a need to insulate stainless steel pipes, it is advisable to choose a suitable insulation material specifically designed for pipe insulation, rather than attempting to use polyphthalamide, which is not commonly used for this purpose.

- Q:Can stainless steel pipes be used for natural gas systems?

- Yes, stainless steel pipes can be used for natural gas systems. Stainless steel is a highly durable and corrosion-resistant material, making it suitable for transporting natural gas safely and effectively.

- Q:Can stainless steel pipes be used in food processing industries?

- Stainless steel pipes find widespread use in the food processing industry. This material possesses remarkable durability and resistance to corrosion, making it capable of enduring the challenging conditions and elevated temperatures frequently encountered in food processing plants. Moreover, its non-reactive nature guarantees that it won't interact with food or affect its flavor, rendering it a secure option for transporting diverse food products. Furthermore, stainless steel pipes facilitate effortless cleaning and maintenance, thus ensuring the fulfillment of hygiene standards within the food processing sector.

- Q:How do you clean stainless steel pipes?

- To clean stainless steel pipes, you can start by using a mixture of warm water and mild soap to scrub the surface of the pipes with a soft cloth or sponge. Make sure to rinse well and dry thoroughly to prevent water spots or streaks. For tougher stains or buildup, you can use a stainless steel cleaner or polish specifically designed for this purpose. Always remember to follow the manufacturer's instructions and test any cleaner on a small, inconspicuous area before applying it to the entire pipe.

- Q:Are stainless steel pipes suitable for petrochemical plants?

- Yes, stainless steel pipes are highly suitable for use in petrochemical plants. Petrochemical plants handle highly corrosive substances, extreme temperatures, and high pressure conditions, making it essential to use materials that can withstand such harsh environments. Stainless steel pipes offer excellent corrosion resistance, ensuring they can withstand the corrosive nature of petrochemicals without deteriorating or compromising the integrity of the pipes. Additionally, stainless steel has high temperature resistance, making it suitable for the extreme heat encountered in petrochemical processes. Stainless steel pipes also have excellent mechanical properties, providing strength and durability required for high-pressure applications in petrochemical plants. Moreover, stainless steel is a hygienic material that does not contaminate the substances being transported, making it ideal for maintaining the purity of petrochemicals. Overall, stainless steel pipes are a reliable and preferred choice for petrochemical plants due to their corrosion resistance, temperature resistance, mechanical properties, and hygienic nature.

- Q:What is the difference between seamless and ERW stainless steel pipes?

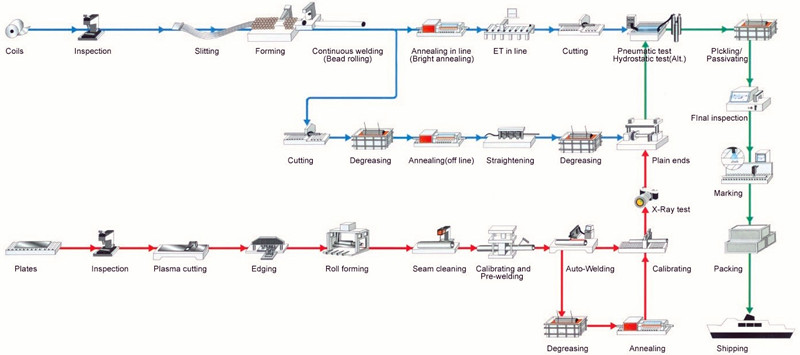

- Seamless stainless steel pipes are made by extruding a solid billet through a piercing rod to create a hollow tube, while ERW (Electric Resistance Welded) stainless steel pipes are formed by rolling a strip of steel into a tube and then welding the edges together using an electric current. The main difference is the manufacturing process, with seamless pipes having no welded seams, making them stronger and more suitable for high-pressure and high-temperature applications. On the other hand, ERW pipes are more cost-effective and commonly used for lower-pressure applications.

- Q:Can stainless steel pipes be used for desalination plants?

- Yes, stainless steel pipes can be used for desalination plants. Stainless steel is highly resistant to corrosion, making it an ideal material for transporting seawater in the desalination process. Additionally, stainless steel pipes offer excellent strength and durability, ensuring long-term reliability in such harsh environments.

- Q:What are the common types of fittings used with stainless steel pipes?

- The common types of fittings used with stainless steel pipes include butt-weld fittings, socket-weld fittings, threaded fittings, and compression fittings. These fittings ensure secure connections between stainless steel pipes, allowing for efficient and reliable fluid or gas flow.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

hot rolled seamless stainless steel pipe

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords