High tenacity industry 1000d FDY low melting polyester filament yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

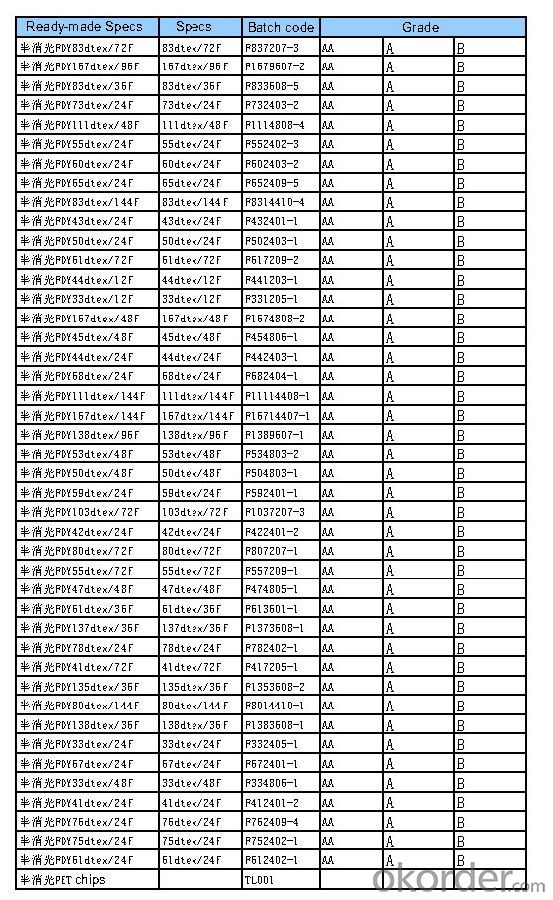

Specification | 11-167dtex, 12-144F |

Regular Specifications

Structure:

1). sheath-core structure: low melting polyester+polyester, Low melting polyester content:30%~40%

2). 100 pure low melting polyester

Feature:

Low melting polyester will be melted at 110/180 degree Celsius and be endowed with adhesive property.

Use low melting polyester is harmless, and enhances the strength of the fabric.

The fabric made with low melting polyester yarn is with high strength, washable, stiff and smooth, easy care.

Low melting polyester yarn owns good adhesiveness and stability, adhesive quickly.

The processing is simple, low energy consumption, nonhazardous, no pollution, Eco-friendly.

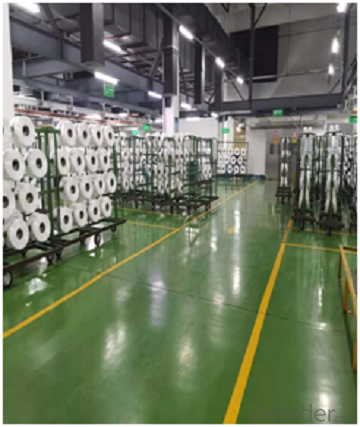

Package of FDY Yarn

The FDY yarned is packed by plastic film, paper board, foam board and wooden pallets. Each pallets is about 640-720kg. Box package is also available.

Advantage of Us:

Subsidiary of Stated-owned group, reliable and trustable

Industry leader in the PET chip and yarn fields

On time delivery and prompt response

Well-funded and accept different kinds of payment terms

- Q:How to reduce the cost of textile yarn dyeing

- 3, water and electricity state control, you can not save 4, the equipment is the previous, and now do not expand the scale, for the time being

- Q:What does JC40S cotton yarn mean?

- Cotton yarn is made of cotton fiber by spinning the yarn, processed by the stock after the cotton thread. According to the different spinning process, can be divided into carded yarn and combed yarn.

- Q:What is the cheese yarn?

- Now some new spinning machines (such as rotor spinning, commonly known as air spinning) can be directly spun out conical or cylindrical cheese yarn.

- Q:Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- 2. Use Cotton yarn is widely used, it can be used as woven yarn, can also be used as knitting yarn, especially combed yarn can be used to produce high quality textile products, such as high-grade T-shirt, fine poplin, cotton Can produce special industrial ...

- Q:What is the yarn in the textile

- The naked eye can be seen, generally can be hand picked out, but some of the fabric organization is not to pick, specifically to try their own.

- Q:What is the difference between mesh cloth and Bali yarn?

- Mesh cloth can not clean the fade, you can hand wash and machine wash, the banner of the screen color bright and soft, and not fade

- Q:Textile spinning mill management system

- The cube net table in this regard is done in place, both from the supplier, procurement, production, to sales, are able to provide timely data and synchronization, can make the various departments of the staff through the query can understand their own The information and circumstances required.

- Q:What is the process of towel in the textile?

- Electronic jacquard machine without the need to design a good program, including the flower and auxiliary needle control, dobby machine to design the program, if it is the most original machine to design a spike and shuttle steel plate, Organize the design of the pattern of the organization.

- Q:What is the difference between textile sizing and paper making?

- The modified starch used in papermaking is mainly: acid modified starch (surface sizing), oxidized starch (surface sizing, coating), phosphate starch (surface sizing, coating), oxidized acetate starch (coating) Cationic starch, amphoteric starch (pulp added), grafted starch (coated. Market less) a technology is not up to standard, and then a cost can not accept

- Q:How much does it cost to do a small cotton textile mill?

- General brocade and roll machine together to sell together. A Qinghua with 3-5 sets of carding, two parallel, 1-2 sets of coarse sand machine, 8-16 spinning machine!

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

High tenacity industry 1000d FDY low melting polyester filament yarn

- Loading Port:

- Dalian

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 5000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches