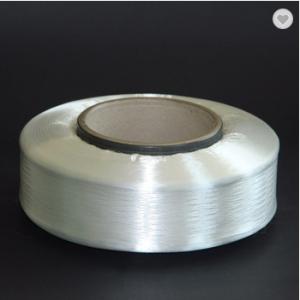

Polyester Filament Yarn ATY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Material: | 100% Nylon | Yarn Type: | Nylon 6 | Pattern: | Raw |

| Style: | V | Feature: | V | Use: | Knitting,Weaving |

| Twist: | v | Evenness: | v | Yarn Count: | v |

| Strength: | v | Place of Origin: | Brand Name: | ||

| Model Number: | ACELON-7 |

Packaging & Delivery

| Packaging Detail: | by case |

| Delivery Detail: | 30 days |

Specifications

1. 100% Made in Taiwan.

2. Polyester filament Yarn ATY

Polyester filament Yarn ATY

FEATURE:

ATY is so called spun-like yarn. Owing to hairy feeling like natural cotton, it’ s also called cotton-like yarn. Polyester Filament ATY is light weight, wear resistant, easy to clean and quick dry. It is suitable for sports wears, casual wears and jackets. (*ATY: air textured yarn)

APPLICATIONl:

Fashion apparel, sports wears, beach shorts, casual jackets

| LUSTER | DENIER / FILAMENT | YARN SHAPE | CHARACTERISTIC |

| SD | 150/192170/144 | Round | Semi Dull Spun-like, cotton-like |

- Q:There are several yarns of textile mills

- In the special yarn: in the special yarn 21 to 32 special (British 19 to 28 British branch) of the yarn. Such yarns are suitable for medium and thick fabrics such as medium cloth, gabardine, khaki and so on. 3. Fine yarn: fine yarn refers to 11 to 20 special (British 29 to 54 British branch) of the yarn. Such yarns are suitable for thin fabrics, such as fine cloth, poplin and the like. 4. Special fine yarn: special fine yarn refers to 10 special and below (British 58 British branch and above) of the yarn.

- Q:How good is the textile economy?

- The requirements of the warping have three points: uniform tension, uniform yarn, winding density uniform.

- Q:What are the benefits of the steaming machine to the textile industry?

- (4) knitting process, the coil forming uniform; (5) the size of the finished product size and stability; (6) no additional humidification system; (7) to eliminate static electricity.

- Q:How to reduce the cost of textile yarn dyeing

- Suggested to find a way out of the product, do different things, do not and the general dyeing factory on the line of homogeneous competition, to make their own company's characteristics!

- Q:What is the cheese yarn?

- So that the length of the yarn to take over and remove the yarn defects and impurities in the winder through the tank or the reciprocating guide yarn rewinding into the boundless or side, and into a certain shape (such as conical, Shape), a certain volume of the winding volume of the tube

- Q:Why in general the yarn in the woven fabric strength coefficient of use greater than 1

- 1. Processing cotton yarn manufacturing methods are more complex, in general, there are two kinds of spinning methods, that is, carded spinning and combing spinning. (1) carded spinning process: with cotton → open cotton → carding → parallel → roving → spun yarn → post-processing → finished product inspection. (2) combing spinning process: with cotton → open cotton → carding → strip → strip → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q:Textile spinning mill management system

- Textile spinning mill management system "is a management software for textile spinning enterprises. Through the basic information, raw material management, production management, sales management, payroll management, account management, inventory management and statistical query eight functional modules To achieve the internal management of enterprises

- Q:What is the yarn inside the textile industry is what kind of yarn?

- Direct dye can be stained, is the natural fiber. And then go to the performance of the fiber, the dissolution test, to come to a certain type.

- Q:How much does it cost to do a small cotton textile mill?

- But also have 1-2 sets of tank! Plus what the factory at least 2.5 million! Coupled with the flow of funds, then 3.5 million yo! I only know so much. As for the machine you want to go and the spinning mill to ask, often someone to sell, you can also buy the old machine.

- Q:Textile waste silk (abandoned side yarn) what purpose ah?

- Textile waste silk (discarded yarn) is a non-woven textile raw materials, usually re-opened, non-woven non-woven equipment production, should be 90% of the product is the production of non-woven fabrics. The reason for this is as follows

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Polyester Filament Yarn ATY

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000 m²/month

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

New products

Hot products

Hot Searches

Related keywords