Fully Drawn Yarn FDY Yarn High Strength Eco-Friendly

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description of FDY Yarn

Material | 100% polyester |

Type | FDY (Fully Drawn Yarn), semidull |

Structure | Multifilament Yarn, Continuous Filament |

Color | White and Black |

Feature | Eco-Friendly, High Strength, |

Application | Knitting, Weaving, Sewing, Embroidery |

Specification | 11-167dtex, 12-144F |

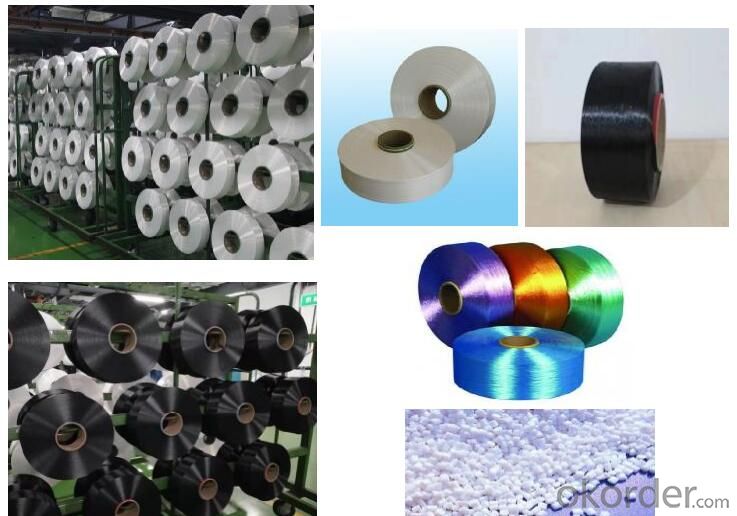

Production Facilities of FDY Yarn

We have the most advanced production system DSC. The whole production process is conducted and supervised by the operating platform. Meanwhile, there are 10 TMT fully automatic winding machine and Robot packaging system which highly improves the production efficiency and avoids manual mistakes.

Production Capacity of FDY Yarn

The production capacity is 200,000 TONS per year for now and it will be of 500,000 per year after the erection of the second production line.

Package of FDY Yarn

The FDY yarned is packed by plastic film, paper board, foam board and wooden pallets. Each pallets is about 640-720kg. Box package is also available.

Advantage of Us:

1. Subsidiary of Stated-owned group, reliable and trustable

2. Industry leader in the PET chip and yarn fields

3. On time delivery and prompt response

4. Well-funded and accept different kinds of payment terms

- Q:What are the types of textile yarns?

- Artificial fiber: rayon (RAYON) also known as artificial cotton rayon (VISCOSE), blended fiber: long / short fiber blended yarn, there are T / RT / C two, with brightness: semi-light yarn / Triangular light yarn to processing points:

- Q:What is the reason why the yarn is spinning

- Jingwei yarn is naturally based on the geographical latitude and longitude of the call, horizontal called weft, parallel to the cloth called warp,

- Q:Textile class 21 yarn, 32 shares of what is the meaning of goods ah

- Such as the yarn, 21 is a single yarn, 32 shares, equivalent to 16 yarn. So 32 shares more than 21 single yarn to be thick. The yarn is also more expensive than the single yarn.

- Q:What is the textile bobbin?

- It overcomes the outer yarn of the cheese yarn is easy to be humidified, and the inner layer of the inner wall of the tube is still dry, resulting in the inner layer yarn and the outer layer of the humidity is not consistent, not easy to knit or wool shortcomings, so that the cheese yarn humidification evenly.

- Q:Will the following kind of yarn which fine? A32 support, B21 support

- 32 branch is relatively small. "Count" is used to indicate the degree of textile fiber thickness of the unit, the higher the number that the fiber, the count is divided into the number of imperial and metric number

- Q:What does JC40S cotton yarn mean?

- Cotton yarn production methods are more complex, in general, there are two kinds of spinning methods, that is, comb cotton spinning and combing spinning. (1) carding cotton spinning process: with cotton → open cotton → carding (2) combing spinning process: with cotton → open cotton → carding → combing → parallel → roving → spun yarn → post-processing → finished product inspection.

- Q:There are several kinds of yarn in textile mill

- Many varieties of yarn, different performance. It can be made of natural fibers or a variety of chemical short fibers made of pure spinning, it can be mixed by several fibers made of blended yarn, but also by the chemical fiber directly from the filament yarn processing

- Q:What is the yarn inside the textile industry is what kind of yarn?

- Direct dye can be stained, is the natural fiber. And then go to the performance of the fiber, the dissolution test, to come to a certain type.

- Q:How good is the textile economy?

- Uniform tension: including a single yarn within each single tension and uniformity of the yarn tension, shaft and shaft tension between the uniform

- Q:What is Artex and Artex Products?

- Analysis of the industry that, with the improvement of living standards and aesthetic concepts, foreign Artex product market will be further expanded, the development potential is huge.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fully Drawn Yarn FDY Yarn High Strength Eco-Friendly

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 500000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords