FRP grating in the big plant and big industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification:

FRP molded grating made of vertical and horizontal continuous fiberglass fully soaked in unsaturated polyester resin giving perfect bi-directional mechanical properties. Combining unmatched corrosion resistance with strength, long life and safety, molded grating provide the ultimate in reliable performance, even in the most demanding corrosive conditions. Besides, it is easy to cut and install. CNBM offer the widest selection with panel sizes, colors and slip resistant surfaces, clients can avail FRP grating your specific requirements.

Product Features:

- Light but high loaded strength

- High anti-corrosion and anti-aging

- Easy installation and maintenance

- Low maintenance

- Non-conductive

- Lowest in life cycle cost

- Corrosion Resstance

- Anti-slippery

- Various sizes and color available

Colour Design:

To satisfy customer's design project, CNBM grating offers a wide selection of grating colors to choose from. The standard colors available for fiberglass grating as following:

- Blue

- Red

- Yellow

- Green

- Light Grey

- Dark Grey

Custom colors of fiberglass grating may be available upon request, you can contact us learn more.

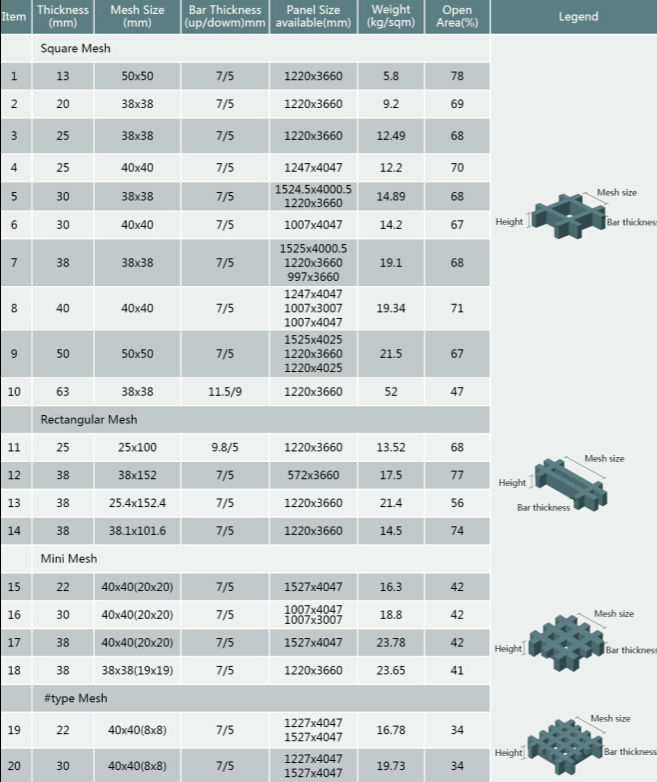

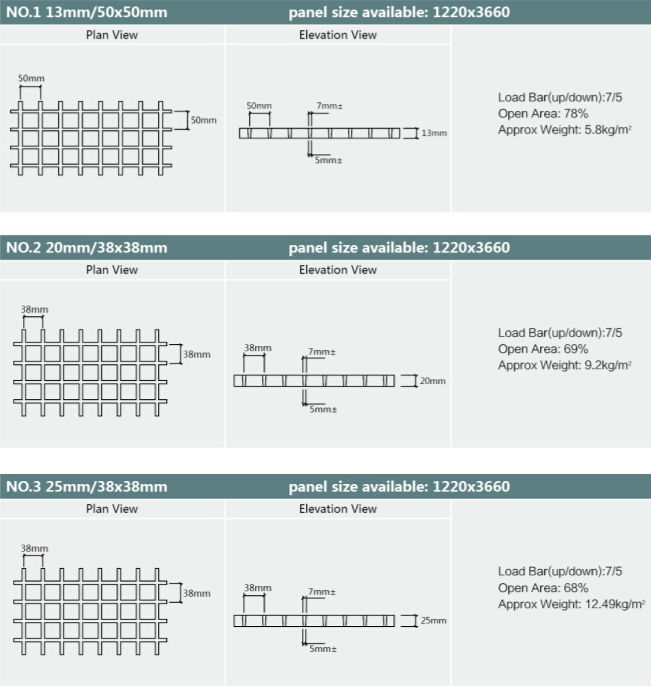

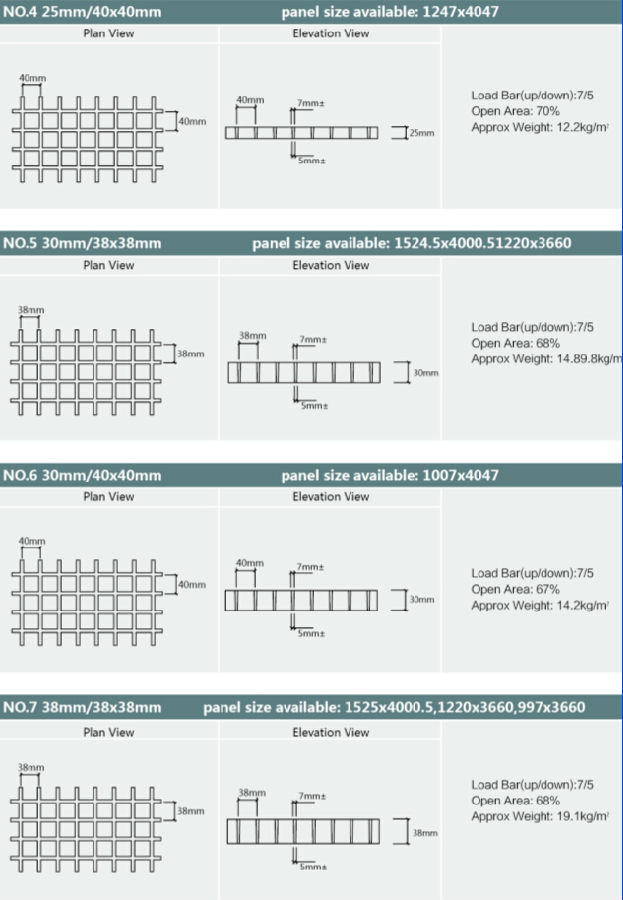

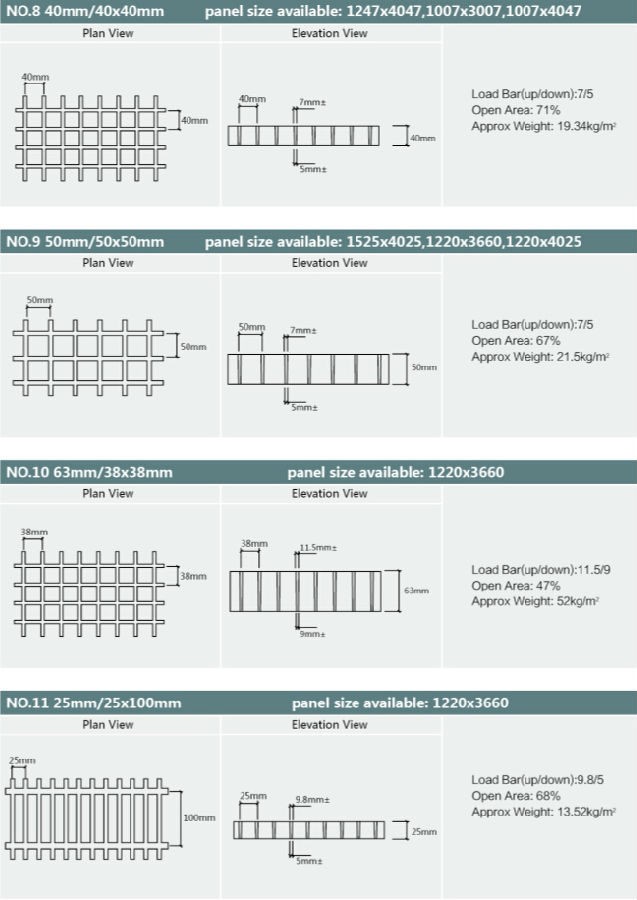

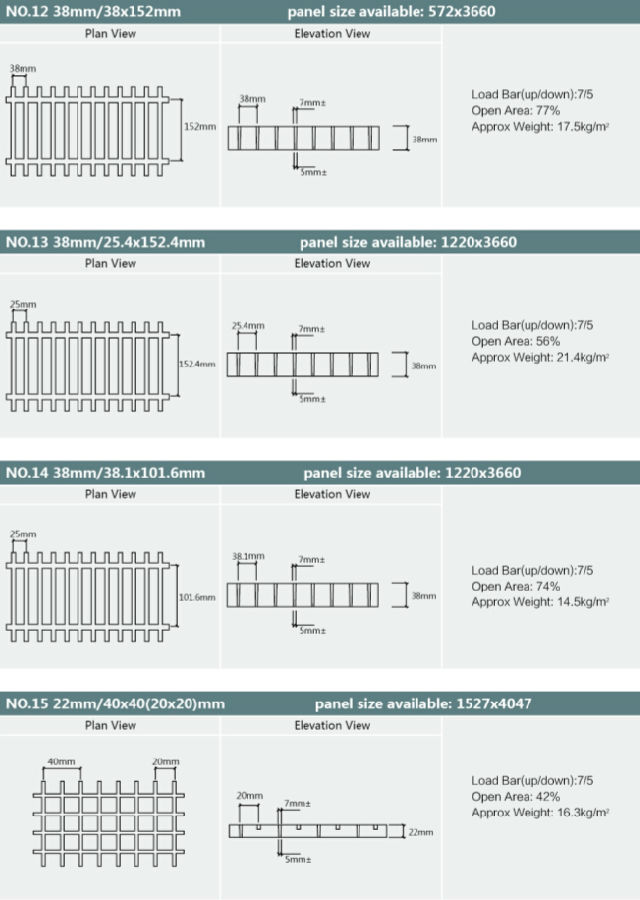

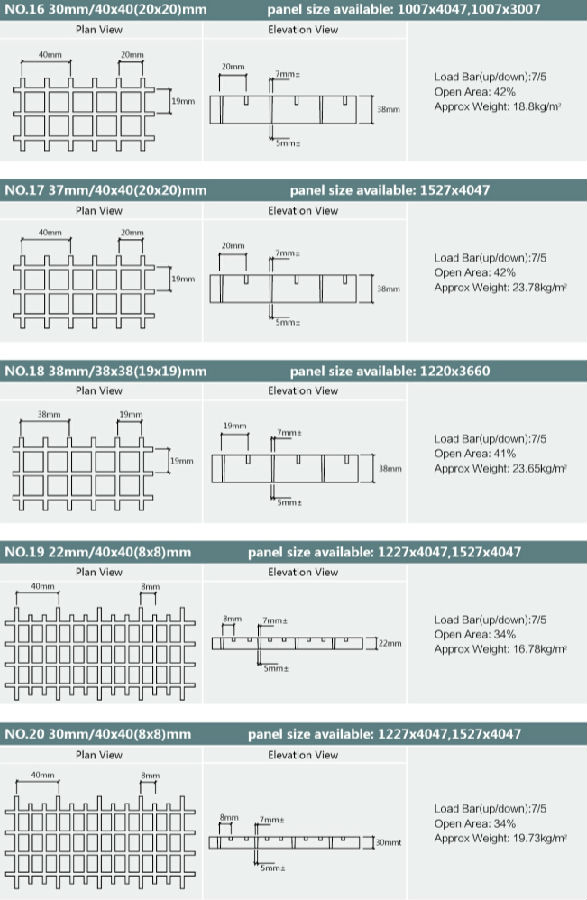

Moded Grating Sizes List:

- Q:Can FRP pultrusion profiles be used in electrical insulation applications?

- FRP pultrusion profiles are capable of being utilized in electrical insulation applications. They possess exceptional electrical insulation properties, rendering them appropriate for a broad range of electrical applications. The superior dielectric strength of FRP materials ensures the efficient containment of electrical currents within designated pathways, thus preventing leakage and electrical hazards. Moreover, FRP profiles exhibit low electrical conductivity, thereby decreasing the likelihood of electrical shorts and enhancing overall safety in electrical insulation applications. The non-magnetic characteristics of FRP materials are also advantageous as they eliminate the potential for electromagnetic interference (EMI) in sensitive electrical systems. Furthermore, FRP pultrusion profiles are lightweight, resistant to corrosion, and boast a lengthy operational lifespan. This renders them an economical and robust solution for electrical insulation applications.

- Q:Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP, or fiberglass reinforced plastic, offers excellent strength, durability, and corrosion resistance, making it a suitable material for water slide components. The pultrusion process allows for the production of customized profiles with specific shapes and dimensions, ensuring compatibility with water slide design requirements. Additionally, FRP's lightweight nature simplifies installation and maintenance while providing a safe and enjoyable experience for water slide users.

- Q:How do FRP pultrusion profiles perform in heavy-load applications?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their exceptional performance in heavy-load applications. Due to their high strength-to-weight ratio, these profiles can withstand substantial loads without compromising structural integrity. The pultrusion process ensures that the fibers are uniformly distributed and aligned along the length of the profile, resulting in superior strength and stiffness. In heavy-load applications, FRP pultrusion profiles exhibit excellent load-bearing capabilities. They have a high modulus of elasticity, meaning they can resist deformation under heavy loads, ensuring long-term durability. These profiles also have a high ultimate tensile strength, allowing them to withstand extreme forces without breaking or deforming. Furthermore, FRP pultrusion profiles are corrosion-resistant, making them ideal for heavy-load applications in harsh environments. Unlike traditional materials like steel, FRP does not rust or corrode, ensuring a longer lifespan and reduced maintenance costs. Another advantage of FRP pultrusion profiles in heavy-load applications is their electrical insulation properties. They do not conduct electricity, making them suitable for environments where electrical conductivity is a concern. Additionally, FRP pultrusion profiles are lightweight compared to traditional materials like steel or concrete. This characteristic not only simplifies transportation and installation but also reduces overall project costs. In summary, FRP pultrusion profiles perform exceptionally well in heavy-load applications. Their high strength-to-weight ratio, excellent load-bearing capabilities, corrosion resistance, electrical insulation properties, and lightweight nature make them a preferred choice for various industries, including construction, infrastructure, marine, and transportation.

- Q:Can FRP pultrusion profiles be used in the automotive industry?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles can definitely be used in the automotive industry. FRP pultrusion profiles offer several advantages that make them suitable for automotive applications. Firstly, FRP pultrusion profiles are lightweight, which is a crucial factor in the automotive industry as it helps in improving fuel efficiency and reducing overall vehicle weight. Lighter vehicles have lower energy consumption and emissions, making them more environmentally friendly. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratio. This means they can provide high strength and stiffness while being lightweight. This property makes them ideal for structural components in automobiles, such as chassis, body panels, and support structures. Furthermore, FRP pultrusion profiles are highly corrosion-resistant, which is a significant advantage in automotive applications. Vehicles are often exposed to harsh environmental conditions, including moisture, salt, and chemicals. The corrosion resistance of FRP helps in ensuring the longevity and durability of automotive components, even in challenging environments. Additionally, FRP pultrusion profiles have good impact resistance, which is crucial for automotive safety. They can absorb and dissipate energy during impacts, reducing the risk of injury in case of accidents. Moreover, FRP pultrusion profiles can be customized and engineered to meet specific design requirements, allowing for versatility in automotive applications. They can be designed to have specific mechanical properties, shapes, and sizes, making them suitable for various automotive components. Overall, the lightweight, high strength, corrosion resistance, impact resistance, and customization options make FRP pultrusion profiles an excellent choice for the automotive industry. They offer numerous benefits, including improved fuel efficiency, enhanced safety, and prolonged component life, making them a viable alternative to traditional materials in automotive applications.

- Q:What are the typical applications for FRP pultrusion profiles?

- FRP pultrusion profiles have a wide range of uses in different industries. In construction, they are commonly used for structural components like beams, columns, and platforms. These profiles have a high strength-to-weight ratio, are corrosion resistant, and durable, making them perfect for long-lasting, low-maintenance infrastructure. In transportation, FRP pultrusion profiles are used to manufacture lightweight components for buses, trucks, railcars, and wind turbines. Their lightweight nature helps reduce fuel consumption and increase energy efficiency. Additionally, they can withstand chemicals, moisture, and UV radiation, ensuring their durability in harsh environments. In the electrical and power distribution field, FRP pultrusion profiles are utilized for manufacturing insulating supports, cable trays, and ladder racks. These profiles offer excellent electrical insulation properties, making them a safe and reliable choice for electrical installations. Furthermore, their non-conductive nature helps prevent electrical accidents and eliminates the risk of electric shock. In the marine industry, FRP pultrusion profiles are ideal for manufacturing boat hulls, decks, and other marine components due to their resistance to saltwater corrosion. Their high strength and stiffness enable them to withstand the tough conditions of the marine environment. Additionally, FRP pultrusion profiles are used in the chemical processing industry for manufacturing tanks, pipes, and platforms. They are resistant to various chemicals and corrosive substances, ensuring the equipment's integrity and enhancing safety in chemical plants. Overall, FRP pultrusion profiles have diverse applications in industries such as construction, transportation, electrical, marine, and chemical processing. Their unique properties make them a versatile and dependable choice for various structural and functional needs.

- Q:Can FRP pultrusion profiles be used in the construction of solar panel frames?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of solar panel frames. FRP pultrusion profiles are lightweight, strong, and resistant to corrosion, making them an ideal material choice for solar panel frames. The durability and high strength-to-weight ratio of FRP pultrusion profiles ensure that the frames can withstand various weather conditions and long-term exposure to sunlight. Additionally, FRP pultrusion profiles can be easily customized to meet specific design requirements, allowing for flexibility in the construction of solar panel frames. Overall, the use of FRP pultrusion profiles in solar panel frame construction offers numerous advantages, making it a suitable choice for the solar energy industry.

- Q:Are FRP pultrusion profiles resistant to seismic activity?

- FRP (Fiber Reinforced Polymer) pultrusion profiles are known for their high strength-to-weight ratio and excellent mechanical properties. However, when it comes to seismic activity, their resistance depends on various factors. In general, FRP pultrusion profiles can exhibit good resistance to seismic activity due to their inherent properties. The composite materials used in their construction, such as fiberglass and resin, offer high tensile strength and stiffness, making them capable of withstanding dynamic loads caused by earthquakes. Moreover, FRP pultrusion profiles have been extensively tested and proven to possess excellent fatigue resistance. This property is crucial during seismic events as structures are subjected to repeated dynamic loading. The ability of FRP profiles to withstand cyclic loading without suffering from fatigue failure significantly enhances their seismic resistance compared to traditional materials like steel or concrete. Another advantage of FRP pultrusion profiles in seismic activity is their lightweight nature. Their low weight reduces the overall mass of the structure, resulting in lower seismic forces. This weight reduction can lead to reduced seismic responses and less damage during an earthquake. However, it is important to note that the seismic resistance of FRP pultrusion profiles can be influenced by various factors. These include the design and quality of the profiles, the connection details, and the overall structural system in which they are used. Proper engineering and design considerations must be taken into account to ensure optimal performance and seismic resistance. In conclusion, FRP pultrusion profiles have the potential to offer good resistance to seismic activity due to their high strength, stiffness, and fatigue resistance. However, their performance in seismic events depends on various factors, and careful design and engineering practices are essential to maximize their seismic resistance.

- Q:Are FRP pultrusion profiles resistant to ultraviolet radiation?

- Yes, FRP pultrusion profiles are generally resistant to ultraviolet radiation. The combination of the composite material and the resin used in pultrusion manufacturing provides excellent UV resistance, making them suitable for outdoor applications.

- Q:Can FRP pultrusion profiles be used in high-voltage applications?

- Yes, FRP pultrusion profiles can be used in high-voltage applications. FRP (Fiber Reinforced Polymer) is a highly durable and electrically insulating material, making it suitable for use in high-voltage environments. The pultrusion process used to manufacture FRP profiles ensures that the material has a consistent and uniform composition, resulting in excellent electrical insulation properties. FRP pultrusion profiles have a high dielectric strength, meaning they can withstand high voltages without electrical breakdown. They also exhibit low electrical conductivity, preventing the flow of electric current through the material. This makes FRP profiles an ideal choice for applications where electrical insulation is crucial, such as high-voltage power transmission and distribution systems, electrical substations, and electrical equipment insulation. In addition to their electrical insulation properties, FRP pultrusion profiles offer several other advantages in high-voltage applications. They are lightweight, corrosion resistant, and have a high strength-to-weight ratio, making them easy to handle, install, and maintain. FRP profiles are also non-magnetic and non-conductive, reducing the risk of electromagnetic interference (EMI) in sensitive electrical systems. Overall, FRP pultrusion profiles are a reliable and efficient choice for high-voltage applications, providing excellent electrical insulation, durability, and performance in challenging environments.

- Q:Can FRP pultrusion profiles be used in the aerospace industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the aerospace industry. These profiles offer numerous advantages such as high strength-to-weight ratio, corrosion resistance, and design flexibility. They can be used in various aerospace applications including structural components, interior parts, and electrical systems. Additionally, their non-conductive properties make them suitable for applications where electrical insulation is required.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FRP grating in the big plant and big industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 8000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords