Fiberglass Bituminous Waterrpoof Roofing Membrane Felt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

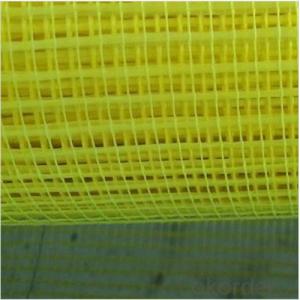

Roofing membrane,breathable roofing membrane,waterproof roofing membrane,permeable roofing membrane,membrane for underlay,roofing felt,waterproof roofing felt,Bituminous roofing felt,Bituminous membrane,Asphalt Felt,Bituminous felt,

Description:

It is designed for use as a type of underlay on roofs with tiles, slates or steel tiles. This underlay can be also used to provide extra security under tiles when sub-roof sheets are used. The edges have been reinforced in order to boost its tear resistance, improve the nail holds and enable the product to withstand rough treatment.

It has a glass fiber core that has been impregnated with bitumen. The core is coated on both sides with stabilised bitumen and the surface is coated with fine slate granules. The edges of this underlay has been reinforced with polypropylene felt to provide excellent tear resistance and good purchase for nails.

Specfications:

1/, Weight/sqm: 550gr, 750gr, 1200gr, 1500gr, etc;

2/, Roll size: 1X20m, 1X30m, etc;

3/, CE approved.

4/, Special requirements can be manufactured as client's requirements.

- Q:Can glass fiber grid cloth be fiberglass reinforcing material?

- Glass reinforced plastics refers to using glass fiber to reinforce polyester, epoxy resin and phenolic resin. Glass reinforced plastics, also called glass fiber reinforced plastic fiberglass is reinforced plastics made of glass fiber or its products.

- Q:Powder modified asphalt polyester blanket is a lower quality waterproofing material made of powder instead of polymer. Glass fiber gridding cloth reinforced waterproof coiled material uses waterproof coiled material as base

- Glass fiber gridding cloth reinforced waterproof coiled material Waterproof coiled material Difference: the quality of polyester reinforcement is higher than fiberglass reinforcement.

- Q:glass fiber mesh, I want to start business and I want to have several sets of looms, but I have no market so my friend help me.

- you can set up a Taobao shop to sell virtual goods. it is very profitable and the investment is very small.

- Q:Waht should be noticed when laying fiber mesh plaster in inner wall? Is it not allowed to lap while laying mesh? Where it is 10cm in doorframe should be paved.

- What is very general is that mesh lapping is not enough in these parts, and tips are treated improperly or palster mortar is not sealed closely, thus causing rain leakage and even thermal bridges. In recent years, domestic completion of the new building has many wall leakage in windowsill, gutter spout funnels, cornice,etc. due to poor thermal insulation construction. And to stop leakage is very difficult because the leakage point is not easy to be found. 4. Due to unfirm pasting of polystyrene board, there are more and more quality problems. The most serious situation is the falling-of accident of polyphenyl board, and the reason is: a. Poor quality of construction and insufficient cement pasting area cause falling off; b. mishandling of the old wall; 5. Using unqualified materials. a. Use neutral or low-alkali fiberglass mesh. b. The volume-weight of polystyrene board is not enough. Its compressive strength and shear strength are low. c. No use of polymer cement bonding. d. Cement strength level is not enough. Solutions (a) the choice of adhesive mortar

- Q:The products of alkali plastic coated glass fiber mesh cloth

- The product has the advantages of stable structure, high strength, good alkali resistance, corrosion resistance, crack resistance, etc., and the enhancement effect is the best, and the construction is simple and easy to do. Mainly used for cement, gypsum, wall, building and other structures to enhance the internal and external surface, crack prevention, is a new type of building materials insulation project.

- Q:Joints of different materials on wall need to be pasted with steel mesh or fiberglass mesh, and the parallel position with beam column must be pasted, then what about the unparallel position?

- When it deforms but there is slab staggering, it would be curved. Pasting in advanced should be till that plastering is parallel with wall. It also needs to be pasted. The unparallel position should on the same wall surface. There will be cracks and plaster might fall off.

- Q:what's the executive standard of alkali resistant mesh? What is the test method?

- JGJ144-2004 is external wall thermal insulation. Technical Specification GB20102-2006-T glass fiber mesh alkali resistance test method for sodium hydroxide solution soaking?method.

- Q:In what circumstances do you need to paste the mesh, if not, it is okay?

- Posting mesh is better, it can also level up by burnt gypsum and then plaster putty.

- Q:How to combine fiberglass mesh and interior wall?

- They are combined by cracking resistant mortar.

- Q:What is the construction method of external wall thermal insulation mesh

- before pasting the mesh, the screed-coat should be scraped on the thermal insulation base, and then paste the mesh with the trowel gently pushed, and then a layer of cracking resistant mortar is scraped thinly at the outer layer of mesh, so that mesh in the outer layer of cracking resistant mortar plays a role in the cracking resistant. Besides, it can not first paste mesh and the withwash cracking resistant mortar.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Fiberglass Bituminous Waterrpoof Roofing Membrane Felt

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords