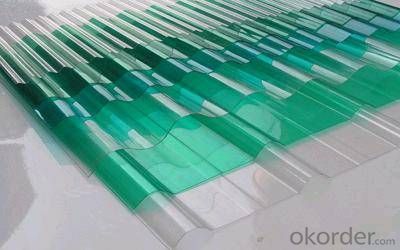

FIBER REINFORCE PLASTIC Transparancy Skylight Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

FRP Skylight Panel:

1,Energy-saving

2,Heat-resistant material

3,Insulated against noise

4,Good quality

Features:

1) Owing to adopting continuous forming machinery, the length of theproducts is

not limited by product technique (except for transport equipment), any lengthand any section of panel can be made.

2) Excellent weather resistant property: surface is coated with ageingresistant film, which almost filters all UV light, the service life can be aslong as 20 years, greatly reduces the material cost and construction costbrought about by factors like the frequent change of PC boards

3) Good impact resistance and flexural strength make sure the translucentpanel can resist against the hit of hail and heavy typhoon

4) Excellent thermal stability: fiberglass panel belong to thermosettingfiber glass reinforced plastics, the thermal expansion coefficient is 2.2 x 10- 5cm/cmoc; PC (polycarbonate) are thermoplastics, the thermal expansion coefficientis 6.8 x 10 - 5cm/cmoc. When applied in big span buildings, the relativedisplacement of PC panel are too big, which results in the cracking andbreakage of hole position of screws, water leakage is virtually unavoidable

5) Fiberglass translucent panel are designed more personalized: FRP isheterogeneous material which can transform the direct light into diffusedlight, make the bright sunshine soft light friendly to man's eyes. The diffusedlight creates a comfortable working space (better effect in the region

6)General panels like PC, create direct light , which make the brightnessin the room uneven and cause man's eyes fatigued, overfocus makes floor orobjects change colors.

Heatnsulating property. The K (heat transfer coefficient) is small as2.0W/m2K. According to the test report issued by National Center forQuality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-304R, refer to GB/T8484-2008), the result shows GRP of thicknessof 50mm, K is 2.0W/m2K.

Fire resistance: class B. According to the test repot issued by National Center for Quality Supervision & Test of Fire Equipment (No.: Zb200921913), refer to GB8624-2006, the result achieves class B.

Smooth surface, up to 85% in light transmittance. According to the test report issued by National Center for Quality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-305G), refer to GB/T2680-1994, GRP of thickness of 50mm, the transmittance is up to 85%. In sunny days, the illumination indoors can reach to 1000 lux. Refer to DIN 5035, the illumination in public place just needs 500 lux, and 200 lux is enough in workshop. Though it is high in transmittance, light pollution is not existed.

Sound isolation: 28dB. According to the test report issued by National Center for Quality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-304S), refer to GB/T50121-2005, GRP of thickness of 50mm, sound isolation is 28dB.

Wonderful mechanical performance, which is shown in high elasticity and impact resistance. According to the test report issued by National Center for Quality Supervision & Test of Building Engineering (No.:BETC-QC1-2009-305DA), refer to GB/T9962-1999, result shows the vertical flexural strength is 131MPa, the lateral one is 124MPa, and the bending strength is more than 80MPa.

Long service life: at least 30years. GRP enjoys good performance in light and UV light resistance, and passed long-time exposure experiment.

High safety- hard to broken. Those doors, windows, curtain walls, partition panels, etc. used commonly in public areas, industrial plants and warehouses presently can be replaced to avoid maintenance in winter.

Light in weight: GRP of thickness of 50mm, it is 6.8Kg/m2 in weight.

It is of no pollution, and has good performance in erosion resistance (oxidation, acid, alkali, salt, oil and grease resistance). If destructive fire happens, GRP will be burned to be water, co2, co and dust, exclusive of nitride, sulfide, halogen or heavy metal. The product of combustion is low in toxicity, even lower than the one of pine, the result of smoke toxicity test is class ZA3.

- Q:Are FRP pultrusion profiles resistant to alkaline substances?

- FRP pultrusion profiles are known for their general resistance to alkaline substances. By using fiberglass reinforced polymer (FRP) in pultruded profiles, they acquire excellent resistance against a wide range of chemicals, including alkaline substances. The manufacturing process typically involves using a thermosetting polymer, such as polyester or vinyl ester, as the resin. This choice of resin ensures high resistance to alkaline solutions. Additionally, the fiberglass reinforcement adds strength and durability to the profiles, making them highly resistant to corrosion and degradation caused by alkaline substances. However, it is important to note that the specific resistance of FRP pultrusion profiles to alkaline substances may vary depending on the resin formulation and manufacturing process used. Therefore, it is advisable to consult the manufacturer or supplier to confirm that the profiles meet the specific resistance requirements for alkaline environments.

- Q:How do FRP pultrusion profiles perform in earthquake-prone areas?

- FRP (Fiber Reinforced Polymer) pultrusion profiles perform exceptionally well in earthquake-prone areas due to their inherent properties. The high strength-to-weight ratio of FRP materials provides excellent resilience against seismic forces. Additionally, FRP pultrusions have high flexural strength, which enables them to withstand bending and torsional loads during earthquakes. Moreover, FRP profiles are corrosion-resistant, making them ideal for long-term durability in areas prone to seismic activity. Overall, FRP pultrusion profiles offer a reliable and robust solution for structural applications in earthquake-prone regions.

- Q:Can FRP pultrusion profiles be used in the construction of railway sleepers?

- Yes, FRP pultrusion profiles can be used in the construction of railway sleepers. FRP (Fiber Reinforced Polymer) offers high strength, durability, and corrosion resistance, making it a suitable material for railway applications. The pultrusion process ensures consistent quality and allows for the customization of profiles to meet specific requirements. Additionally, FRP pultrusion profiles are lightweight and have excellent electrical insulation properties, making them an ideal choice for railway sleepers.

- Q:Can FRP pultrusion profiles be used in the construction of elevated walkways?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of elevated walkways. FRP pultrusion profiles are lightweight yet strong, making them an ideal choice for creating durable and long-lasting walkways that can withstand heavy foot traffic. They offer excellent corrosion resistance, making them suitable for outdoor applications where exposure to moisture, chemicals, and UV radiation is a concern. FRP pultrusion profiles also have high strength-to-weight ratios, allowing for easy installation and reducing the structural load on the supporting elements. Moreover, FRP profiles are non-conductive, making them a safer option for walkways in areas where electrical hazards are present. Overall, FRP pultrusion profiles offer numerous advantages that make them well-suited for the construction of elevated walkways.

- Q:Are FRP pultrusion profiles resistant to humidity or moisture?

- Yes, FRP pultrusion profiles are highly resistant to humidity or moisture due to their non-porous nature and the use of corrosion-resistant materials.

- Q:Can FRP pultrusion profiles be used in wastewater or sewage treatment plants?

- Yes, FRP pultrusion profiles can be used in wastewater or sewage treatment plants. FRP (Fiber Reinforced Plastic) materials offer excellent corrosion resistance, high strength-to-weight ratio, and durability, making them suitable for harsh environments like wastewater treatment facilities. These profiles can be used for various applications such as gratings, handrails, ladders, walkways, and structural supports, providing a long-lasting and low-maintenance solution for these facilities.

- Q:Is the test standard for FRP pultruded profiles and FRP gratings the same?

- Not the same. You can consult Hao Hao testing company (national level)

- Q:What is the impact resistance of FRP pultrusion profiles?

- FRP pultrusion profiles exhibit a remarkably high level of impact resistance. These profiles are produced by pulling reinforcing fibers, such as fiberglass, through a resin bath and then into a heated die, where the resin solidifies and cures. This manufacturing technique generates a durable and robust composite material with exceptional mechanical properties, including impact resistance. The impact resistance of FRP pultrusion profiles may differ depending on the specific formulation, design, and orientation of the reinforcing fibers employed. Nevertheless, in general, FRP pultrusion profiles have been proven to possess superior impact resistance when compared to traditional materials like steel or aluminum. The combination of reinforcing fibers and the resin matrix in FRP pultrusion profiles provides enhanced strength and toughness, enabling the profiles to withstand substantial impact loads without cracking, breaking, or deforming. Consequently, these profiles are highly suitable for a diverse range of applications where impact resistance is of utmost importance, such as in construction, transportation, and sporting goods. Furthermore, the impact resistance of FRP pultrusion profiles can be customized by adjusting factors such as fiber content, fiber orientation, and resin type during the manufacturing process. This allows for tailored profiles that meet specific application requirements. In summary, FRP pultrusion profiles deliver outstanding impact resistance due to the integration of reinforcing fibers and resin matrix. Their exceptional strength, toughness, and ability to endure impact loads make them a dependable choice across various industries and applications.

- Q:Are FRP pultrusion profiles resistant to impact?

- FRP pultrusion profiles exhibit a general resistance to impact. The amalgamation of robust fibers and the polymer matrix employed during manufacturing renders FRP profiles exceptionally enduring, enabling them to endure substantial impacts without fracturing or shattering. Furthermore, the pultrusion process guarantees the uniform dispersion of fibers within the profile, thereby bolstering its capacity to resist impact. Consequently, FRP pultrusion profiles are ideally suited for impact-prone applications, including construction, transportation, and infrastructure ventures.

- Q:Are FRP pultrusion profiles resistant to high winds or hurricanes?

- FRP pultrusion profiles offer exceptional resistance against high winds and hurricanes. Combining the robustness of fiberglass with the longevity of polymers, FRP is a lightweight yet remarkably sturdy material that can endure severe weather conditions. Extensive testing has proven that FRP pultrusion profiles exhibit outstanding wind resistance properties. They possess a remarkable stiffness-to-weight ratio, enabling them to withstand the powerful forces generated by high winds without deformation or breakage. Additionally, the inherent flexibility of FRP permits it to absorb and distribute wind forces, minimizing the risk of damage. In the face of hurricanes, FRP pultrusion profiles have demonstrated their capability to withstand the intense winds and airborne debris associated with such extreme weather events. They have been successfully employed in various applications, including building facades, bridges, and utility poles, in areas prone to hurricanes. Moreover, FRP pultrusion profiles possess corrosion resistance, providing an extra advantage in withstanding high winds and hurricanes. Unlike traditional materials like steel or wood, FRP profiles do not rust or decay when exposed to moisture, making them even more suitable for these demanding weather conditions. Overall, with their exceptional strength, durability, flexibility, and corrosion resistance, FRP pultrusion profiles are an excellent choice for applications requiring resistance against high winds or hurricanes.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

FIBER REINFORCE PLASTIC Transparancy Skylight Panel

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords