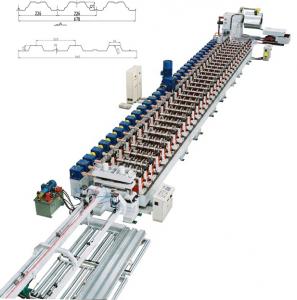

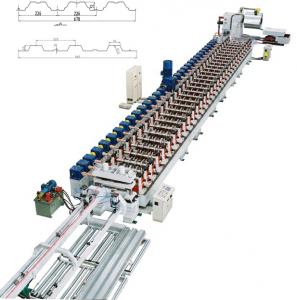

Electrical Heater Cover Roll Forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Set Per Year set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General information of Electrical Heater Cover Roll Forming Machine:

Name | Electrical Heater Cover Roll Forming Machine | |

Description | This machine is used to roll form the covers of electrical heaters | |

Main Parts | ||

(1) | Hydraulic Decoiler | 1 set |

(2) | Leveling Device | 1 set |

(3) | Punching Device | 1 set |

(4) | Feeding Device | 1 set |

(5) | Roll Forming M/C | 1 set |

(6) | Straightening Device | 1 set |

(7) | Hydraulic Cutting Device | 1 set |

(8) | Run-out Table | 1 set |

(9) | Hydraulic Station | 1 set |

(10) | PLC Control System | 1 set |

(11) | Simple Safety Mesh | 1 set |

Line Speed | About 5 m/min | |

Flow Chart: | Coil loading ---- decoiling ---- leveling ---- feeding ---- punching ---- feeding ---- roll forming ---- cutting ---- run-out | |

Lead Time | 90 - 120 days/set | |

MinOrder | 1 set | |

Package | In bulk | |

Technical data of Electrical Heater Cover Roll Forming Machine:

Main Parameter | ||

(1) | Feeding Width | 250mm |

(2) | Rolling Thickness | 0.6 - 1.0mm |

(3) | Rolling Materials | Pre-painted steel coils |

(4) | Rolling Speed | About 6m/min |

(5) | Voltage | 380V/50HZ/Three Phase |

(6) | Yield Strength | ≤235Mpa |

(7) | Number of Rollers | About 18 sets of rollers |

(8) | Material of Roller | GCr15(HRC58-62) |

Reference pictures of Electrical Heater Cover Roll Forming Machine:

- Q:How is the molding machine installed?

- The position of the embedded parts of the forming machine should be accurate and firm, and the foundation should meet the design requirements and meet the strength of the permitted installation.

- Q:How to maintain the molding machine?

- 2 check the vibration platform, mold box and slider, vibrator and indenter beam, feeding settings and the main frame and other parts of the connection bolt is loose;

- Q:What is the roll forming machine?

- And said slider is provided in a slider seat with a dovetail groove structure in the lower part thereof to form a sliding mechanism; said slider block is connected with the main shaft by a taper sleeve method, The disk is fixed by bolts on a fixed plate with two elongated screw holes, one end of which is bolted to the slider and the other end abuts against the mold plate.

1. Manufacturer Overview |

|

|---|---|

| Location | Henan, China |

| Year Established | 1993 |

| Annual Output Value | US$ 5 Million - US$ 10 Million |

| Main Markets | 15.00% Mid East 20.00% Europe 25.00% North America 30.00% SoUth America 10.00% Others |

| Company Certifications | ISO 9001:2000 |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | Tianjin; Qingdao |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 4-10 People |

| Language Spoken: | English; Chinese; Russian |

| b)Factory Information | |

| Factory Size: | Above 10,000-30,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | High; Average |

Send your message to us

Electrical Heater Cover Roll Forming Machine

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1 Set set

- Supply Capability:

- 100 Set Per Year set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords