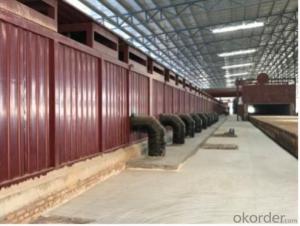

Dry Roasting Equipment---Draught Fan (It can be customized according to specific projects)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product introduction: including hot air blower (smoke heat), moisture exhaust fan (smoke heat), tunnel kiln smoke exhaust fan, kiln tail cooling fan, under-vehicle cooling fan, air supply fan (waste heat), and moisture exhaust fan (waste heat).

Note: It can be customized according to specific projects.

The fan is a machine that relies on the input mechanical energy to increase the gas pressure and discharge the gas. It is a driven fluid machine. Fan is the habitual abbreviation for gas compression and gas conveying machinery in China. Fans include ventilators, blowers, and wind generators.

Fans are widely used in ventilation, dust removal and cooling in factories, mines, tunnels, cooling towers, vehicles, ships and buildings, ventilation and induced draft in boilers and industrial furnaces; cooling and ventilation in air conditioning equipment and household appliances; Drying and selection of grain, air source of wind tunnel and inflation and propulsion of hovercraft, etc.

- Q:What is the best drying equipment?

- The machine will be part of the fan by the air, through the early, middle and high efficiency filter. To 100,000 purification, the steam heat exchanger, so that the air temperature to a certain temperature

- Q:Frozen sublimation drying equipment which consists of several systems

- the control system: the control system consists of a variety of monitoring the original, an umbrella device, instrumentation and other components, a higher degree of automation control system can be set by the freeze-drying process automatically operate, while the vacuum, heating plate temperature and cooling System monitoring and alarm, record all kinds of data.

- Q:How to choose the right drying equipment and drying technology

- Hygroscopic materials can absorb moisture from the surrounding environment, non-hygroscopic materials can not absorb moisture from the environment.

- Q:The working principle of belt dryer

- Drying process is a hot air flow through the material layer, complete the process of heat and mass transfer, the upper cavity connected by the duct and the fan inlet. Most of the gas circulation, part of the lower temperature of the larger moisture content of the gas as exhaust gas through the drainage tube, regulating valve, drain fan discharge. The next cycle of the unit, the fan out of the wind into the upper cavity, down through the heat exchanger heating, through the material layer into the lower chamber, the lower chamber by the side duct and return air duct connected to the fan, most of the gas circulation, Part of the discharge. Up and down the cycle unit according to user needs can be flexible equipment, the number of units can also be selected according to need.

- Q:What is a combination of drying equipment?

- Combination drying equipment is a combination of two or more dry forms, the main material, mainly in series, that is, when the material has been through the drying equipment, two or more drying equipment, combined dry mainly to meet a The need for a drying process.

- Q:What are the characteristics of the drum dryer?

- conventional direct heating rotary drum dryer conventional direct heating rotary drum dryer in the dry material and hot air Direct contact with the way of convection heat drying in accordance with the direction of flow between the hot air and material, divided into parallel and countercurrent.

- Q:What are the common drying methods?

- Mechanical dehydration method is through the way of the material pressure, will be part of the water extrusion. Commonly used in pressing, sedimentation, filtration, centrifugal separation and other methods. Mechanical dehydration method can only remove part of the material free water, combined with water remains Material, so the material after the mechanical dehydration of the material moisture content is still high, generally 40 to 60%, but the mechanical dehydration method is one of the most economical method.

- Q:The development prospects of the dryer

- As an air compressor post-processing equipment, cold and dry machine is only a single auxiliary machine. But with the technological progress, the industrial sector on the gas quality requirements are getting higher and higher, cold and dry machine market will be more and more, it can be said, as long as the air compressor in the development of cold and dry machine prospects will be more and more it is good.

- Q:What are the types of drying equipment?

- he equipment used for the drying operation. Many types. According to the operating pressure can be divided into atmospheric pressure and pressure (vacuum dryer also known as vacuum dryer). According to the operation method can be divided into intermittent and continuous. According to the drying medium can be divided into air, flue gas or other drying medium. According to the movement (material movement and drying medium flow) can be divided into parallel, countercurrent and cross flow.

- Q:What are the basic types of common drying equipment?

- (4) hollow paddle dryer (leaf dryer) hollow paddle dry dryer, also known as leaf dryer, mainly by the jacket with the W-shaped shell and two hollow blade shaft and transmission components. A hollow blade is arranged on the shaft and a rotary joint with a heat medium inlet is provided at the shaft end. The heat required to dry the moisture is conducted to the material by the inner wall of the W-shaped groove with the jacket and the hollow leaf wall.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dry Roasting Equipment---Draught Fan (It can be customized according to specific projects)

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 50 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.