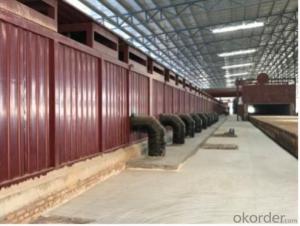

Dry Roasting Equipment---Tunnel Roasting Kiln---Straight Tunnel Kiln---Masonry Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Tunnel roasting kiln can be divided into straight tunnel kiln (with kiln car) and mobile rotary tunnel kiln (without kiln car). Straight tunnel kilns can be further divided into masonry tunnel kilns and prefabricated tunnel kilns in terms of construction methods. The mobile rotary tunnel kiln belongs to the assembled tunnel kiln.

Straight Tunnel Kiln:

(1) Main products: sintered bricks, common bricks, porous bricks, hollow bricks/blocks, roof tiles, hollow wall panels.

(2) According to the different output, the inner width of the tunnel kiln is divided into the following types:

① the inner width is 3.6 and 3.7 meters, suitable for daily output of 150,000-200,000 blocks, and annual output of 50-66 million (common bricks)

② the inner width is 4.6 and 4.8 meters, suitable for daily output of 210,000-250,000 blocks, and annual output of 69-82 million (common bricks)

③ the inner width is 5.4 and 5.6 meters, suitable for daily production of 260,000-300,000 pieces, and annual output of 85-100 million (common bricks)

④ the inner width is 6.9 and 7.2 meters, suitable for daily output of 310,000-400,000 blocks, and annual output of 102-132 million (common bricks)

⑤ the inner width is 9.2 and 9.4 meters, suitable for daily output of 600,000-620,000 pieces, and annual output of 165-200 million (common bricks)

(3) Kiln Body Structure

Masonry Tunnel Kiln:

The kiln wall is a composite wall, and the innermost layer is the working layer in contact with the high temperature. It is usually built with refractory materials (common bricks can be sintered below 600°C). The materials, grades and specifications of the refractory materials used are determined according to the firing temperature of the kiln. The middle layer is the thermal insulation layer, which is composed of various lightweight thermal insulation materials. The selected lightweight thermal insulation materials should not only provide thermal insulation, but also maintain long-term safe use without damage. The outermost layer is a load-bearing protective layer, which is multi-purpose sintering. This layer is mostly built with sintered common bricks and porous bricks to protect the lightweight thermal insulation material from damage and to bear the load of the kiln roof and the transverse thrust of the vault.

The roof of the kiln is a composite kiln item, which is hoisted on site. Commonly used kiln roof structures are refractory fiber module + refractory fiber blanket + sealed castable + steel beam; clay refractory slab + high alumina hanger + refractory fiber blanket + sealed castable + steel beam; light mullite Brick + high-aluminum hanging column + refractory fiber blanket + sealing castable + steel beam.

(4) Firing temperature: 950-1050℃

(5) Firing cycle: 26-40h

(6) Length of tunnel kiln: 110-170m

(7) Length and size of kiln car: It is determined according to the size of the billet stack and the internal and external combustion method. The length and size of the commonly used kiln car are: 3600mm, 3900mm, 4100mm, 4200mm, 4350mm, 4800mm, etc.

(8) Firing method: all internal combustion roasting; all external combustion roasting; combined internal and external combustion roasting.

(9) The roasting kiln is often equipped with a smoke exhaust system, a combustion system, a waste heat system, a backburning system, a cooling system, and a bottom pressure balance system. Each system consists of fans, pipes and regulating valves. The kiln has a large section, high output, small temperature difference between sections, and good thermal insulation performance. Computer automatic monitoring and control system to ensure the stability of thermal parameters and roasting quality

- Q:Frozen sublimation drying equipment which consists of several systems

- refrigeration system: refrigeration unit and freeze-drying chamber, the condenser inside the evaporator and other components. Chillers can be independent of two sets, that is, a set for the freeze-drying room, a set for the condenser, can also be combined with a set of freezer.

- Q:How to choose the right drying equipment and drying technology

- For non-hygroscopic materials, the moisture present in any environment remains on the surface and becomes "surface moisture" and is easily removed.

- Q:What are the common types of dryers?

- Hollow paddle dry dryer, also known as leaf dryer, mainly by the jacket with the W-shaped shell and two hollow blade shaft and transmission device composed of the shaft is arranged in the hollow blade, the shaft is equipped with heat medium

- Q:The working principle of belt dryer

- For the material temperature does not exceed 60oC requirements, can be used about 80oC dry gas. Multi-stage combination can better play the performance of belt dryer, and dry more uniform.

- Q:What are the characteristics of the drum dryer?

- According to the dry material is heated, the current rotary drum dryer can be divided into five types, that is, direct Heating dryer, indirect heating dryer, compound heating dryer, steam calcining dryer, spray granulation drying machine.

- Q:What are the common drying methods?

- Mechanical dehydration method is through the way of the material pressure, will be part of the water extrusion. Commonly used in pressing, sedimentation, filtration, centrifugal separation and other methods. Mechanical dehydration method can only remove part of the material free water, combined with water remains Material, so the material after the mechanical dehydration of the material moisture content is still high, generally 40 to 60%, but the mechanical dehydration method is one of the most economical method.

- Q:How to solve the dryer a series of failures

- The moisture absorption capacity of the dryer is limited, so the moisture it adsorbs must be removed by regeneration. The process is: when the ambient air is inhaled, through a filter into the blower, and then be sent to a group of heaters. The heated air passes through the machine. When the temperature of the dryer rises, the adsorbed moisture is released. When the hot air to absorb water vapor to saturation, it was discharged into the atmosphere. The high temperature regenerative dryer must be cooled before returning to the dry loop to restore the moisture absorption function of the dryer.

- Q:The development prospects of the dryer

- performance, the use of compact heat exchangers, such as plate fin heat exchangers, is promising. (The current difficulties may still be in terms of price). Promotion of the use of green ring-type refrigerant R134a, including cold and dry machines, including all the direction of development of refrigeration equipment, technically there is no insurmountable obstacles. But this is a great social engineering, an industry, a separate action of a business in addition to some commercial publicity significance, the overall goal of the macro is not much practical effect. In the final analysis, this is a government action, the need for the introduction of policies by the state to define a unified time limit.

- Q:What are the types of drying equipment?

- he equipment used for the drying operation. Many types. According to the operating pressure can be divided into atmospheric pressure and pressure (vacuum dryer also known as vacuum dryer). According to the operation method can be divided into intermittent and continuous. According to the drying medium can be divided into air, flue gas or other drying medium. According to the movement (material movement and drying medium flow) can be divided into parallel, countercurrent and cross flow.

- Q:What are the basic types of common drying equipment?

- (3) drum scraper dryer drum scraper dryer is through the rotation of the cylinder, heat conduction way, will be attached to the outer wall of the cylinder liquid material or ribbon material, a dry continuous operation of equipment The The material to be dried is passed from the upper tank into the receptacle of the drum dryer. The drying drum is driven at the specified speed by the drive.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Dry Roasting Equipment---Tunnel Roasting Kiln---Straight Tunnel Kiln---Masonry Tunnel Kiln

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 50 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.

Xi'an Research and Design Institute of Wall & Roof Materials Co,.Ltd.