Energy-saving/Environmental pu sandwich panel/siding/decorative panel

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

l CAPACITY FOR CONTAINERS:

The 20" GP container takes around 1000 m² sidings;

The 40" HQ container takes around 3500 m² sidings.

l MOQ (Minimum Order Quantity):

Single color siding (each model): 100 m²; Double color siding (each model): 200 m²

l WHAT IS THE DELIVERY TIME:

It takes half day to deliver the products from our company to the nearest port (Dalian Port, China).

l WHAT ARE THE TERMS OF PAYMENT:

We accept T/T payment. We start to manufacture after receiving 30% - 50% of the total payment, and the rest of payment must be made before the shipment.

l DIMENSION OF SIDING:

height: 375mm or 385mm; length: 3800mmor 4000mm; thickness: 16mm.

l PACKAGING:

8 or 9 piece in each package; Dimension of each package is 420x140x3840mm; weight of each package is around 47.5kg.

Packaging & Delivery

| Packaging Detail: | Package Size: 3840*420*140mm Package Quantity: 9 pieces/pack Unit Weight: less than 5.5kg/piece Gross Weight: 47.5.5kg/pack 40ft. Container: 3500 sq.meters; 20ft. Container: 1100 sq.meters; |

| Delivery Detail: | 1day |

Specifications

*pu sandwich panel

*Thermal Insulation & Energy-saving

*Easy Installation & Cost Reduction

*Reliable & Long-lasti

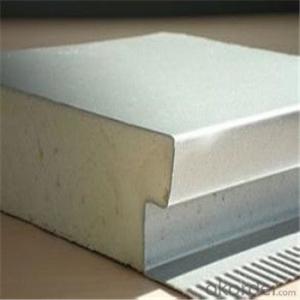

pu sandwich panel Composition

CNBM consists of three layers: the top material is special aluminum-zinc coated metal board, the core material is rigid high-density Polyurethane foaming with fire-retardant treatment, and the back material is fiber foil paper.

Product Features

Since CNBM pu sandwich panel itself has the characteristics of insulation, water-proof and fire-retardant, lightweight anti-seismic, convenient construction, sound insulation and lower noise, environment friendly, and lasting beauty etc., in the meanwhile since its assembly method of its siding body is simple and practical, without being limited by the seasons and environment, the installation is very safe and convenient, suitable for four seasons.

- Q:Reinforced concrete and metal sandwich board how much difference

- Tower crane driver, scaffolding type of work, all kinds of welding workers

- Q:This is not required, the requirements of the interval of the wall to meet the fire requirements of fire resistance or fire time requirements. The Applicable Scope of Molybdenum Sandwich Panel

- Color steel sandwich panels have the effect of thermal insulation, these two types of panels can be used for houses and workshops, are able to waterproof

- Q:Polyurethane sandwich panels in the polyurethane is what material, what are the benefits of industrial building materials should choose polyurethane?

- It should be, for example, naphthalene anthracene, and several rings are capable of forming a closed conjugate system. Generally speaking, more than four benzene rings are fused (for example, 1.2-benzo, 3-methyl Anthracene, etc.) are mostly carcinogenic substances, which are mostly anthracene derivatives, the relationship between the mechanism of carcinogenesis and structure is not yet fully understood ...

- Q:3 side of the wall surrounded by color steel ~ the other side of the water ~ Will the three sides of the gap with the wall how to waterproof ~ Question added: whether you can use the blowing agent, the top of the same thing (which tell me what) And then sealed with black glue. More

- I have a veteran to sell, because I just bought a new Taiwan, the price of ..

- Q:Are sandwich panels suitable for automotive showrooms?

- Sandwich panels are an ideal option for automotive showrooms. Comprised of two outer layers or skins with a lightweight core material in between, these panels offer exceptional strength and insulation qualities. They are versatile and can be utilized in various ways, including building facades, partitions, and interior walls. Within automotive showrooms, sandwich panels can be employed to construct walls, ceilings, and even floors. They bring numerous advantages that make them perfect for this setting. Firstly, they provide excellent insulation, ensuring a comfortable temperature inside the showroom regardless of external weather conditions. This is crucial for creating a pleasant atmosphere for both customers and staff. Moreover, sandwich panels are lightweight and easy to install, allowing for efficient and fast construction. This is advantageous for automotive showrooms, as they often face tight deadlines and need to become operational as soon as possible. The panels can be easily cut and shaped to fit specific design requirements, offering flexibility in creating unique and appealing showroom layouts. Additionally, sandwich panels possess excellent noise reduction qualities, guaranteeing a quieter environment within the showroom. This is significant in providing a comfortable ambiance for customers and enabling them to focus on the showcased vehicles. Furthermore, sandwich panels are durable and require minimal maintenance. They are resilient against corrosion, moisture, and fire, providing a long-lasting and safe solution for automotive showrooms. Additionally, the outer layers of the panels can be customized with various finishes and colors, allowing for the incorporation of branding and aesthetic preferences into the showroom design. In conclusion, sandwich panels are a suitable choice for automotive showrooms due to their insulation properties, ease of installation, noise reduction capabilities, durability, and customization options. They offer a cost-effective and efficient solution for creating a functional and visually appealing environment to showcase vehicles.

- Q:Sandwich board does not spray primer afraid of deformation! Can be sprayed after the sale of wallpaper that can not stick can not paste! Do not know there is no way to deal with the next!

- The price of the foam board depends on its density, the higher the density, the more expensive the price

- Q:Color steel sandwich board on the price of how much?

- Solid wood particle board moisture-proof effect than the wood sandwich board moisture-proof effect is better than the solid wood particle board and wood sandwich board difference . solid wood particle board, is made of wood or other lignocellulosic material, after the application of adhesive Heat and pressure under the action of synthetic wood-based panel. Solid wood particle board as a new, high-grade environmentally friendly substrate. Solid wood particle plate inside the cross-scattered structure of the granular. So the nail force is good, you can nail round nails, screws. These machinability is significantly better than MDF. . solid wood particle density is higher, the board of wood fiber particles larger, more to retain the nature of natural wood, in the use of solid wood particles on the board content is generally less than 5%, better environmental protection. Solid wood grain plate warp deformation small, stable size, good, high strength, good stiffness, hanging heavy clothing is not easy to bend. At present in the European furniture market, the use of wood-based panel is also solid wood particle board. . wood sandwich panels inside and outside the two sides for the glass plate, sandwich layer waterproof plywood, the German vacuum technology from high pressure compound. Sandwich panel surface smooth, dirt can be easily removed, the entire panel colorful, with excellent light-blocking. . fiberglass plate surface has a layer of excellent performance gel coat, the atmosphere, water and the general concentration of acid, alkali, salt and other media has a good chemical stability; surface finish, excellent light retention, no discoloration, corrosion resistance , Anti-sun, anti-aging. The main application areas: dry cargo compartment, large span structure roof, wall, purification plant, high profile portfolio housing, container rooms and so on.

- Q:The stove is dedicated to the plastic used for plastic paper

- Fire level and density does not matter, with the lighter point can not fully explain the problem, b1 level to compound gb8624b1 level

- Q:Will the use of color steel sandwich panels ceiling package package how much money a square? M14 round steel to do hanging bars, 950 sandwich panels, the main bone 160 * 60 * 20 * 2.5 C steel Is the workshop ceiling, I should quote how much appropriate,

- In fact, you can also choose the ceiling, the effect of the ceiling may be better.

- Q:Steel structure workshop roof load is the number of specific Please thank you

- Contents The first chapter of the construction site safety technical information management of the main contents and requirements Section I construction site safety technical information management of the meaning of Section II of the construction site safety technology management system Section III construction site safety technical information Four sections of the construction site safety technical information classification The second chapter of the construction site safety management information Section I in progress construction safety supervision and related documents (the first file box) Section II safety production responsibility system (the second file box) third (The third file box) Section IV of the safety of the construction organization design (the fourth file box) Section V Division (sub-project) Safety Technology to the end of the (fifth file box) Section VI security check (sixth file Box) Section VII of the safety education (the seventh file box) Section VIII of the pre-class security activities (eighth file box) Section IX special operations certificates (ninth file box) Section X accident (the tenth file box ) Section XI Safety signs (eleventh file box) Section XII security equipment and machinery and equipment related to the management of documents (the twelfth file box) thirteenth Machinery and equipment, facilities acceptance test records (thirteenth file box) Section XIV construction of temporary electricity (the fourteenth file box) Section fifteenth civilized construction (fifteenth file box) trade union labor protection information

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Energy-saving/Environmental pu sandwich panel/siding/decorative panel

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords