Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Carbon Welding Electrode /Titanium Welding

Quick Information for Carbon Welding Electrode:

Class: ER1100

AWS: A5.10

Conforms to Certification: AWS A5.10 ASME SFA A5.10

Weld Process: Tig (GTAW)

Specifiaction of Carbon Welding Electrode:

AWS Chemical Composition Requirements | |

Cu = 0.05 – 0.20 | Al = 99.0 min |

Mn = 0.05 max | Si + Fe = 0.95 max |

Zn = 0.10 max | Be = 0.0003 max |

Other = 0.05 each – 0.15 total | |

Available Sizes:

Upon Request, call for more information

Characteristics of Carbon Welding Electrode:

Type ER1100 can be used to weld base materials types 1060, 1070, 1080, and 3003.

Welding Filler Wire

Heat Exchangers

Food Handling Equipment

Rivets

Main Features of Carbon Welding Eletrode:

The proper choice of aluminum filler metal mainly depends on the base metal properties to be achieved and welding technique. Post weld cracking, corrosion resistance and behavior under elevated temperature also need to be taken into consideration. Cracking usually can be minimized by choosing a filler metal alloy of higher alloy content then the base metal.

Deposited Chemical Composition % (Typical)

Deposited chemistry is influenced by many factors so no typical analysis can be reported.

Deposited All Weld Metal Properties %

As-Welded

Deposited all weld metal properties are influenced by many factors such as weld process used, so no typical weld metal properties can be reported.

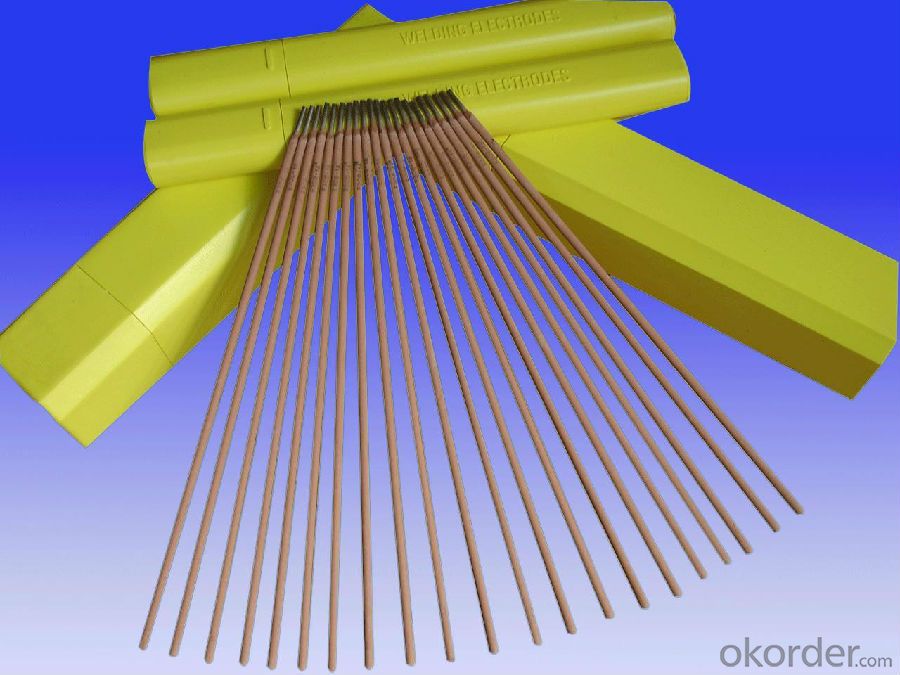

Pictures:

- Q:Can stainless steel wire be used for wire mesh?

- Yes, stainless steel wire can be used for wire mesh.

- Q:How can the stainless steel tube be made of silk?

- Thin wall stainless steel pipe can not be set, usually with a special extrusion machine thread extrusion or extrusion connection.

- Q:Is stainless steel wire suitable for architectural mesh applications?

- Yes, stainless steel wire is highly suitable for architectural mesh applications. Stainless steel is a versatile material that offers excellent corrosion resistance, durability, and aesthetic appeal, making it a popular choice for architectural applications. The wire's strength and malleability allow for intricate designs and patterns that can enhance the aesthetic value of buildings and structures. Architectural mesh made from stainless steel wire offers various benefits. Firstly, it provides a high level of transparency while maintaining privacy and security. The mesh can be woven in different patterns and densities, offering varying degrees of openness and visibility. This makes it suitable for applications such as facades, partitions, sunshades, and cladding systems. Additionally, stainless steel wire mesh is highly durable and long-lasting, even when exposed to harsh environmental conditions. It is resistant to corrosion, UV radiation, and fire, ensuring the mesh retains its structural integrity and aesthetics over time. This durability makes it suitable for both indoor and outdoor applications, including building facades, ceilings, and decorative elements. Moreover, stainless steel wire mesh can be customized to meet specific design requirements. It can be woven into different shapes, sizes, and patterns, allowing architects and designers to create unique and visually appealing structures. The mesh can also be coated or colored to provide additional customization options. Overall, stainless steel wire is a highly suitable material for architectural mesh applications due to its corrosion resistance, durability, customization options, and aesthetic appeal. It offers a combination of functionality and visual appeal, making it a preferred choice for architects and designers in various architectural projects.

- Q:Can stainless steel wire be used for wire EDM machining?

- Yes, stainless steel wire can be used for wire EDM (Electrical Discharge Machining) machining. Wire EDM is a precision machining process that uses a thin, electrically conductive wire to cut through a workpiece. Stainless steel wire is often preferred for wire EDM machining due to its high strength, corrosion resistance, and excellent conductivity. It can effectively cut through various materials, including metals, alloys, and even hardened steels. Additionally, stainless steel wire offers good stability, durability, and dimensional accuracy, making it a suitable choice for intricate and precise machining operations.

- Q:Is stainless steel wire suitable for wire rope thimbles?

- Indeed, wire rope thimbles can indeed be used with stainless steel wire. The reason for this lies in the fact that stainless steel possesses exceptional durability and resistance against corrosion, rendering it a superb option for situations where wire rope thimbles will be subjected to unfavorable conditions or moisture. By incorporating stainless steel wire rope thimbles, wire ropes gain extra fortification and safeguarding, effectively preserving their structural integrity and warding off wear and harm. Furthermore, owing to their capacity to endure substantial loads and fight against rust and corrosion, stainless steel wire rope thimbles find frequent employment in marine, industrial, and outdoor settings.

- Q:Can stainless steel wire be used for wire drawing dies?

- Certainly, wire drawing dies can utilize stainless steel wire. Stainless steel, a highly adaptable material praised for its robustness, resistance to corrosion, and exceptional strength, proves to be fitting for a multitude of applications, one of which being wire drawing dies. These dies serve the purpose of diminishing the wire's diameter through the act of pulling it through a die hole. Stainless steel wire drawing dies effectively withstand the forces and friction associated with this procedure. Moreover, they are renowned for their enduring performance and capacity to generate wire of superior quality, consistently maintaining precise dimensions.

- Q:Stainless steel how to make copper imitation drawing effect?

- Effect, you consult with the electroplating factory. There is a painting effect, the matrix is stainless steel, do color paint, such as black, and the paint is dry the surface of red gold powder (anti copper paint) the effect you want. What you say basically belongs to the former.

- Q:Can stainless steel wire be used for surgical instruments?

- Yes, stainless steel wire can be used for surgical instruments. Stainless steel is a popular choice for surgical instruments due to its durability, corrosion resistance, and ability to withstand repeated sterilization. It is commonly used for making surgical needles, sutures, and various other instruments used in surgical procedures.

- Q:Can stainless steel wire be used for making springs?

- Yes, stainless steel wire can be used for making springs. Stainless steel is a versatile material known for its corrosion resistance, high tensile strength, and excellent elasticity. These properties make it suitable for spring manufacturing applications where durability and resistance to rust or corrosion are required.

- Q:Is stainless steel wire suitable for wire rope connectors?

- Yes, stainless steel wire is suitable for wire rope connectors. Stainless steel is known for its corrosion resistance, making it a reliable choice for outdoor and marine applications where the wire rope may be exposed to moisture and other harsh elements. Additionally, stainless steel wire has high tensile strength, allowing it to withstand heavy loads and provide secure connections. It is also durable and long-lasting, ensuring the wire rope connectors will maintain their integrity over time.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Carbon Welding Electrode /Titanium Welding

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords