ASTM 1080 Carbon Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ASTM 1080 Carbon Steel Round Bars

Products Details

1.Characteristics

1) Even material.

2) Good machinability and polishability.

3) High toughness and high plasticity.

4) High abrasive resistance in high temperature.

5) Excellent total hardenability.

6) Low deformability during heat treatment.

7) Better isotropy.

2.Application

1) Diecasting mould(mold, fixed block, upper die, jet nozzle, nitride thimble ).

2) Extrusion die(mold, supporting member, choke blocks).

3) Hot press die. (aluminum, magnesium, copper alloy)

4) Parts, such as cold cutting, overlap, hot shears, wearable parts.

5) Important parts for aviation industry.

We can produce one hundred kinds of products, including cold work tool steel, hot work tool steel, plastic mould steel and many other alloy tool steel. We are mainly supplying tool steels as below aboard:

AISI: D2, D3, D6, D7, A2, A6, A8, A10, H10, H11, H13, H21, S1, S5, S7, O1, O6;

DIN: 1.2080, 1.2316, 1.2343, 1.2344, 1.2379, 1.2510, 1.2601, 1.2713, 1.2714, 1.2767, 1.2842;

JIS: SKD1, SKD11, SKD61, DC53;

GB: Cr12, Cr12MoV, Cr12Mo1V1, 6CrW2Si, 4Cr5MoSiV, 4Cr5MoSiV1, 3Cr2W8V.

3. Chemical composition of steel bar

| Standard | C | Si | Mn | Cr | Ni | P/S ≤ |

| DIN | ≤0.15 | ≤1.0 | ≤2.0 | 18 | 9 | 0.03 |

| GB | ≤0.15 | ≤1.0 | ≤2.0 | 18 | 9 | 0.03 |

4.Material and Grade

| Material | Grade | Material | Grade |

| 8#-10# | φ16-290 | 65Mn | φ40-300 |

| 15# | φ14-150 | 45Mn2 | φ18-75 |

| 20# | φ8-480 | 60Si2Mn | φ16-150 |

| 35# | φ8-480 | 20CrMnTi | φ10-480 |

| 45# | φ6.5-480 | 20CrMnTiB | φ16-75 |

| Q235B | φ6.5-180 | GCr15 | φ16-400 |

| 40Cr | φ8-480 | ML35 | φ8-150 |

| 20Cr | φ10-480 | T8-T13 | φ8-480 |

| 42CrMo | φ12-480 | Cr12 | φ16-300 |

| 35CrMo | φ12-480 | Cr12MoV | φ16-300 |

| 20CrMo | φ12-300 | 3Cr2W8V | φ16-300 |

| 38CrMoAL | φ20-300 | 45Cr50Cr | φ20-300 |

| 5CrMnMo | φ20-450 | 20CrMnMo | φ20-300 |

| 16Mn(Q345B) | φ14-365 | 40Mn2 | φ28-60 |

| 50Mn | φ40-200 | 35Cr | φ55 |

| 15CrMo | φ21 φ24 φ75 | 15Mn | φ32φ170 |

| 25# | φ16-280 | 40CrMnMo | φ80φ160 |

| YF45MnV | φ28-80 | 20CrMnMo | φ20-300 |

| 30# | φ6.5-480 | 27SiMn | φ20-350 |

| 30CrMo | φ28 | Crwmn | φ20-300 |

| 30CrMnTi | φ16-300 | H13(4Cr5MoSiVi) | φ20-300 |

| 60# | φ210 φ260 | 40CrNiMo | φ20-400 |

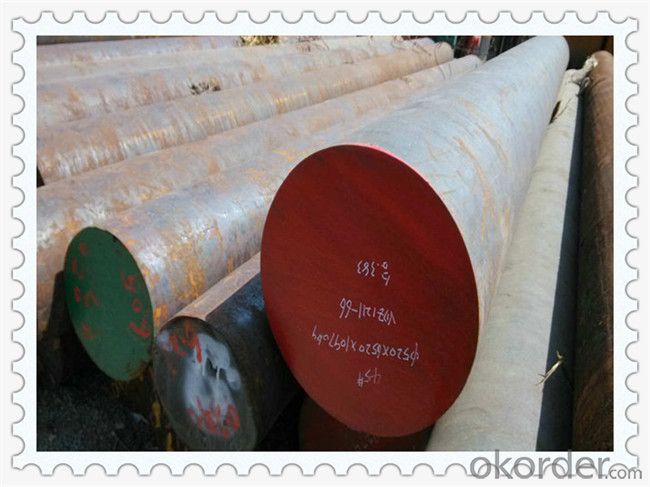

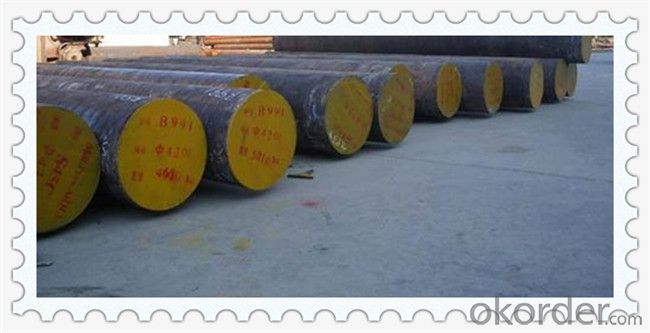

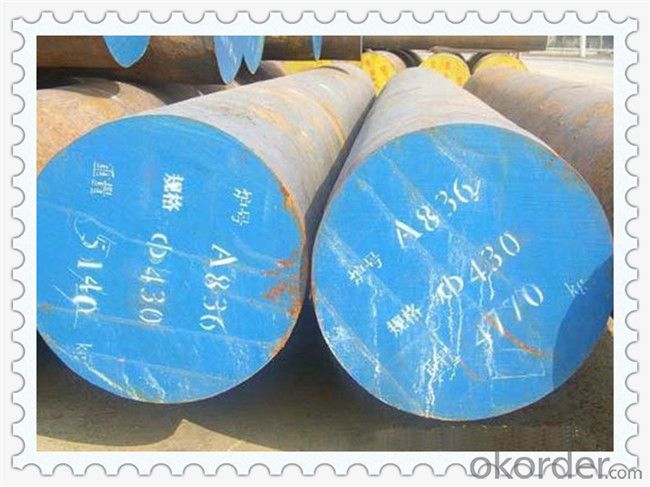

Products Show

Product Overviews

| Product Name | Typical Grades | Diameter(mm) | Standard adopted |

| Carbon Steel | 20 (1020/S20C/C22) | Ø16-Ø300 |

GB/SAE/JIS/DIN

|

| 40 (1040/S40C/C40) | |||

| 45 (1045/S45C/C45) | |||

| Bearing Steel | GCr9 (51100/SUJ1) | Ø12-Ø250 | |

| GCr15 (52100/SUJ2/100Gr6) | |||

| GCr9SiMn (A485-Gr.1/SUJ3) | |||

Cr-Mo Steel | 20Cr (5120/SCr420H/20Cr4) | Ø12-Ø250 | |

| 40Cr (5140/SCr440/41Cr4) | |||

| 42CrMo(4140/SCM440/42CrMo4) | |||

| Gear Steel | 20CrNiMo | Ø16-Ø600 | |

| 20CrMn(5115/SMnC420/20MnCr5) | |||

| 20CrNiMo(8620/SNCM220/20CrMiMo2) |

Application

| Carbon Steel | Mold bottom, Plastic mold, Construction machinery parts Automobile parts, Security grills, Screens, Construction |

| Bearing Steel | Aerospace, Navigation, Nuclear energy, Chemical industry Electronic information, Petrochemical, Instrument and meter Transportation |

| Cr-Mo Steel | Mechanism & Fasteners gear, Stressed components for vehicles Engines and machines, Parts of larger cross-section |

| Gear Steel | All kinds of gears, Statically and dynamically stressed component for vehicles Engines and machine, Larger cross-section parts, Crankshafts |

Work Shop

Company Information

CNBM International Corporation is the most important trading platform of CNBM group.

Whith its advantages, CNBM International are mainly concentrate on Cement, Glass, Iron and Steel, Ceramics industries and devotes herself for supplying high qulity series of refractories as well as technical consultancies and

logistics solutions.

FAQ

1, Your advantages?

professional products inquiry, products knowledge train (for agents), smooth goods delivery, excellent customer solution proposale

2, Test & Certificate?

SGS test is available, customer inspection before shipping is welcome, third party inspection is no problem

3, Factory or Trading Company?

CNBM is a trading company but we have so many protocol factories and CNBM works as a trading department of these factories. Also CNBM is the holding company of many factories.

4, Payment Terms?

30% TT as deposit and 70% before delivery.

Irrevocable L/C at sight.

5, Trading Terms?

EXW, FOB, CIF, FFR, CNF

6, After-sale Service?

CNBM provides the services and support you need for every step of our cooperation. We're the business partner you can trust.

For any problem, please kindly contact us at any your convenient time.

We'll reply you in our first priority within 24 hours.

Packaging & Delivery

1, Packaging: seaworthy package or as required

2, Delivery: 35-45 days or based on quantity

- Q: What is the difference between a bright and a precision ground steel round bar?

- A bright steel round bar and a precision ground steel round bar differ in terms of their surface finish and manufacturing tolerances. The bright steel round bar, also referred to as a bright mild steel bar or a bright mild steel round bar, undergoes a process known as bright drawing. This involves pulling the steel bar through a die to achieve a smooth and shiny surface finish. Consequently, bright steel round bars have a highly polished look and a clean, smooth texture. They are commonly used in decorative applications, such as the production of furniture, automotive accessories, and architectural elements. In contrast, a precision ground steel round bar is manufactured with strict dimensional tolerances and precise surface finishes. These bars are typically produced through the process of precision grinding, where the steel bar is machined to obtain a specific diameter and surface finish. Precision ground steel round bars are renowned for their accuracy and consistency in size, making them suitable for applications that require close tolerances and high precision, such as in the manufacturing of bearings, shafts, and hydraulic cylinders. In conclusion, the primary distinction between a bright steel round bar and a precision ground steel round bar lies in their surface finish and manufacturing tolerances. A bright steel bar boasts a polished appearance and is primarily used for decorative purposes, whereas a precision ground steel bar is machined to precise dimensions and is well-suited for applications that demand high precision and close tolerances.

- Q: What is the difference between a forged and a peeled steel round bar?

- A forged steel round bar and a peeled steel round bar are both types of steel bars used in various industries for different applications. However, there are distinct differences between the two in terms of their manufacturing processes and physical characteristics. A forged steel round bar is made by heating a solid steel billet to a high temperature and then applying pressure to shape it into the desired form. This process involves the use of machinery, such as hammers or presses, to shape the steel and create the round bar. The forging process imparts strength and durability to the steel, making it suitable for applications that require high strength and resistance to wear and tear. On the other hand, a peeled steel round bar is produced through a different manufacturing process known as peeling or turning. In this process, a solid steel bar is rotated against a cutting tool, which removes the outer layer of the bar, resulting in a smooth and precise surface finish. Peeling removes any surface defects or imperfections present in the original bar, improving its dimensional accuracy and surface quality. In terms of physical characteristics, forged steel round bars typically have a rougher surface texture due to the nature of the forging process. This rough texture can provide enhanced grip or adhesion when used in certain applications. Additionally, forged bars often have a denser and more uniform internal grain structure, which contributes to their superior mechanical properties. Peeled steel round bars, on the other hand, possess a smooth and shiny surface finish as a result of the peeling process. This smooth surface makes peeled bars suitable for applications that require aesthetic appeal or require a low coefficient of friction. However, the peeling process may result in a slight reduction in the overall diameter of the bar. In summary, the main difference between a forged and a peeled steel round bar lies in their manufacturing processes and resulting physical characteristics. Forged bars are created through the application of pressure, resulting in a rougher surface texture and superior mechanical properties. Peeled bars, on the other hand, are produced by removing the outer layer of a steel bar, resulting in a smooth surface finish and improved dimensional accuracy. The choice between these two types of bars ultimately depends on the specific requirements of the application at hand.

- Q: What are the typical tolerances for steel round bars?

- The typical tolerances for steel round bars can vary depending on the specific requirements of the application or industry. However, there are generally accepted standard tolerances that are commonly used. For diameter, the typical tolerances for steel round bars are usually within a few thousandths of an inch. This means that the actual diameter of the bar can deviate slightly from the specified diameter, but it will still fall within an acceptable range. In terms of straightness, steel round bars are commonly produced with a straightness tolerance that allows for some deviation from a perfectly straight line. The typical tolerance for straightness is usually measured in units of inches per foot or millimeters per meter. This means that the bar may have a slight bend or curve, but it should not exceed the specified tolerance. Surface finish is another important aspect of steel round bars. The typical tolerance for surface finish is usually specified in terms of roughness average (Ra) or surface roughness in micrometers. This tolerance ensures that the surface of the bar is smooth and free from any significant imperfections, such as pits or scratches. It is important to note that these typical tolerances can vary depending on the specific grade or type of steel being used, as well as the intended application. In some cases, tighter tolerances may be required for precision or critical applications, while looser tolerances may be acceptable for less demanding applications. Therefore, it is always recommended to consult the relevant industry standards or specifications to determine the specific tolerances required for a particular steel round bar.

- Q: What are the advantages of using chromium-vanadium alloy steel round bars?

- Some advantages of using chromium-vanadium alloy steel round bars include: 1. High strength and toughness: Chromium-vanadium alloy steel has excellent strength and toughness properties, making it suitable for applications requiring durability and resistance to wear and tear. 2. Improved corrosion resistance: The addition of chromium enhances the alloy's corrosion resistance, making it resistant to rust and other forms of corrosion, even in harsh environments. 3. Enhanced hardenability: Chromium-vanadium alloy steel can be easily heat-treated to achieve high hardness levels, allowing for increased wear resistance and improved overall performance. 4. Good machinability: The alloy steel round bars can be easily machined and fabricated, making them convenient to work with in various manufacturing processes. 5. Cost-effective: Chromium-vanadium alloy steel offers a good balance between performance and cost, making it a cost-effective choice for many applications compared to other high-performance alloys.

- Q: Can steel round bars be painted?

- Yes, steel round bars can be painted.

- Q: Can steel round bars be used for making shock absorber components?

- Absolutely! When it comes to constructing shock absorber components, steel round bars are a fantastic choice. The reason being, steel possesses exceptional qualities including robustness, longevity, and the ability to withstand wear and tear. By utilizing steel round bars, it becomes possible to craft a multitude of shock absorber elements, including piston rods, mounting brackets, and tube bodies, through either machining or forging methods. The incorporation of steel guarantees that these components can endure the immense pressures and forces linked to shock absorption, thereby ensuring vehicle stability and seamless functionality.

- Q: What are the different types of surface defects that can occur in steel round bars?

- There are several types of surface defects that can occur in steel round bars, including scratches, pits, roll marks, scale, and cracks.

- Q: Can steel round bars be used in the manufacturing of agricultural equipment?

- Yes, steel round bars can be used in the manufacturing of agricultural equipment. Steel is a strong and durable material that provides the necessary strength and structural integrity required for agricultural machinery. It is commonly used in the production of components such as axles, shafts, and supports, making it suitable for various types of farming equipment.

- Q: What are the different cutting methods used for steel round bars?

- The cutting of steel round bars can be done using various methods, depending on the specific requirements and available tools. Here are some commonly used cutting methods: 1. Sawing: Traditional sawing using a saw blade is a cost-effective and simple method suitable for smaller diameter round bars. 2. Abrasive Cutting: When cutting thicker and harder steel bars, abrasive cutting with an abrasive wheel or disc proves to be highly effective. It is often used in industrial applications where precision and speed are crucial. 3. Plasma Cutting: This thermal cutting method involves using a high-velocity jet of ionized gas to melt and remove the metal. It is suitable for cutting steel bars of different thicknesses and is renowned for its speed and precision. 4. Laser Cutting: Laser cutting is an efficient and precise method that utilizes a high-powered laser beam to melt and vaporize the metal. It is commonly employed for cutting intricate shapes and patterns in steel round bars. 5. Waterjet Cutting: Waterjet cutting utilizes a high-pressure stream of water mixed with an abrasive material to cut through steel bars of varying thicknesses and types. It is a versatile method. 6. Shearing: This cutting method involves using specialized machine blades to swiftly and accurately cut smaller diameter round bars. When considering the cutting method for steel round bars, it is crucial to carefully assess the project's specific requirements and consult with experts to determine the most suitable approach.

- Q: Can steel round bars be used in the pharmaceutical industry?

- It is possible to use steel round bars in the pharmaceutical industry. Steel round bars are widely used in different sectors, including pharmaceuticals, because of their strength, durability, and versatility. In the pharmaceutical field, steel round bars can be applied for various purposes, such as producing equipment, machinery, and storage systems. These bars can be utilized to create pharmaceutical manufacturing equipment like mixers, reactors, and centrifuges, which necessitate robust and dependable materials to ensure effectiveness and safety in the production processes. Additionally, steel round bars can be employed in constructing storage systems like racks and shelves, providing a solid and secure solution for organizing pharmaceutical products and supplies. The corrosion resistance and ease of cleaning of steel make it appropriate for maintaining hygienic conditions in pharmaceutical facilities. Overall, steel round bars give the pharmaceutical industry a dependable and cost-effective material choice for diverse applications.

Send your message to us

ASTM 1080 Carbon Steel Round Bars

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords