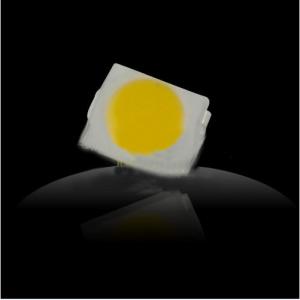

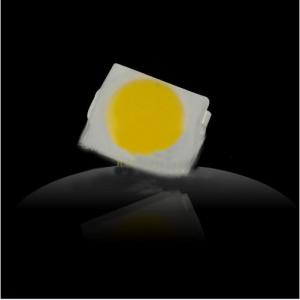

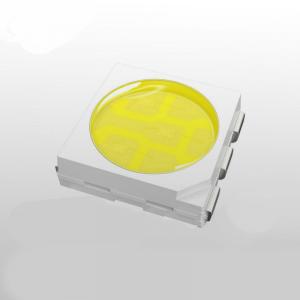

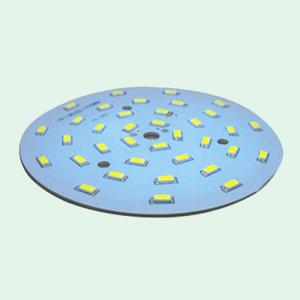

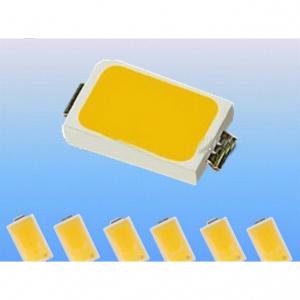

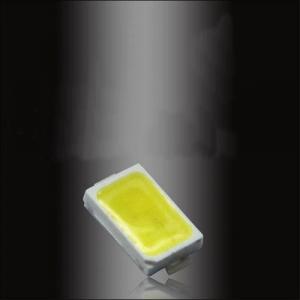

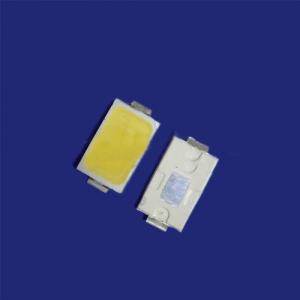

Chip Led 5730

Chip Led 5730 Related Searches

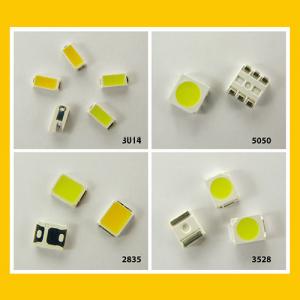

Datasheet Led 5730 Led 3528 Vs 5050 Vs 5630 G50 Led Bulb Led Message Display Board Digital Led Display Board Indoor Led Display Board Led Light Panel Ceiling White Melamine Chipboard Led Bulbs For Spotlights Christmas Led Spotlights Ceiling Led Light Panel White Laminated Chipboard Led Panel Light Ceiling High Lumen Led Flashlight Led Digital Display Board Led Automotive Headlight Led Display Supplier Led Ceiling Light Panel Home Led Lighting System Dimmable Led Panel Light Gu10 Mini Led 35Mm Led Encapsulation Series Black Melamine Faced Chipboard Portable Led Light Panel Suspended Ceiling Led Panel Light Egger Melamine Faced Chipboard Tactical G700 Led Flashlight Aisi 4130 30 Inch Widescreen Monitor Led Track Lighting HeadsChip Led 5730 Supplier & Manufacturer from China

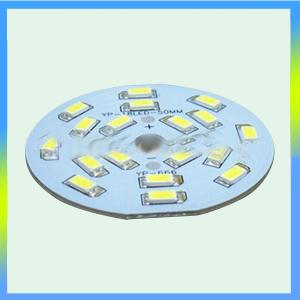

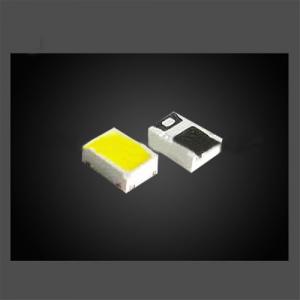

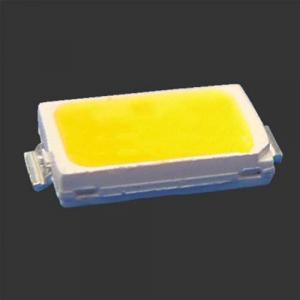

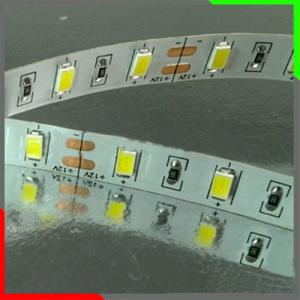

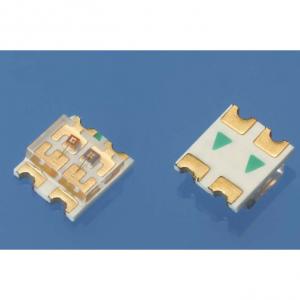

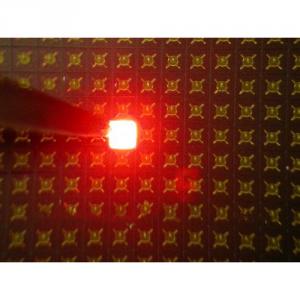

Chip Led 5730 is a high-quality lighting product that features energy-efficient and long-lasting LED technology. This product is widely used in various applications, such as automotive lighting, signage, and general illumination, making it a versatile choice for different usage scenarios. Okorder.com is a reliable wholesale supplier of Chip Led 5730, offering a vast inventory to cater to the needs of various industries and customers.Hot Products