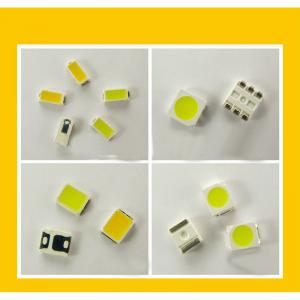

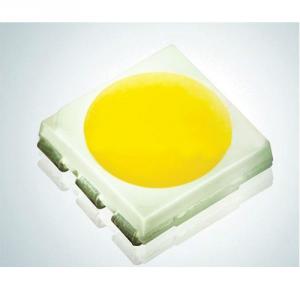

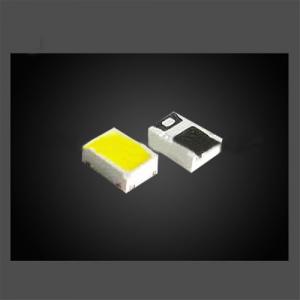

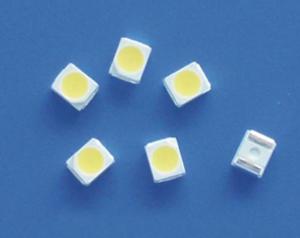

High Lumen 60-65Lm White SMD LED 5730 For LED Bulb

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1 Pc pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications for 5730 smd led white color

| Model | Power | color | intensity | voltage | current | view angle | CCT |

| SL-WZ5730-EM | 0.5w | white | 60-65lm | 2.8-3.5v | 150mA | 120deg | 5500-6000k |

| SL-IZ5730-EM | 0.5w | warm white | 55-60lm | 2.8-3.5v | 150mA | 120deg | 2850-3150k |

(Electro-Optical Characteristics(Ta=25°C)

Parameter | Test condition | Symbol | Value |

Forward voltage | If=150mA | Vf | 2.8-3.5v |

Luminous Flux | If=150mA | Φ | 60-65lm |

Viewing angle at 50% Iv | If=150mA | 2θ 1/2 | 120 Deg |

Reverse current | Vr=5v | Ir | 10µA |

Ra | If=150mA | Ra | 70/80/90 |

Absolute maximum ratings (Ta=25°C)

Parameter | Symbol | Value |

Power dissipation | Pd | 700mW |

Forward current | If | 200mA |

Reverse voltage | Vr | 5V |

Operation temperature range | Top | -35~+85°C |

Storage temperature range | Tstg | -40~+100°C |

Pulse forward current | Ifp | 250mA |

Electrostatic discharge | ESD | 2000(HBV)V |

Soldering temperature | Tsld | 260°C for 10 seconds |

Junction temperature | Tj | 105°C |

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By Sea | 30-40 business days |

1. 3-5 business days for Sample Orders; 7-15 business days for Bulk Orders for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: Production of a number of substrates, the use of SMD LED lights, red lights and green lights are not bad, blue lights appear mass dark, do not know why? Is the LED blue light material easy to use dark?

- When making a batch of LED lights, the brightness values of various lights are in accordance with certain rules. Due to achieve a white balance, three RGB color brightness required by the ratio of 3:6:1, that is to say the blue light required brightness is very low.

- Q: Indoor full color LED display module and LED what is the difference between a full color?

- Indoor full color LED display module and LED chip has three full color difference. The first part: Second: third light emitting display module: maintenance: LED full color display is not easy to maintain. LED full color patch is relatively easy to maintain.

- Q: LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- 3528 single lamp is 0.06W 0.06*60 lamp =3.6W 3528-60 bead is 3.6W/ meters

- Q: How can I install the patch LED lamp belt on the wood chip casting board? With double-sided glue will be hot, and can not use the clip on the screw, what should I do?

- Installed indoors, you can directly tear off the stickers on the 3M double-sided adhesive surface, and then fix the light bar where it needs to be installed. Just press it with your hands.

- Q: Led lamp and Led patch two what is the difference between ah, the feeling is a patch of long service life, whether or not? 5-10 meters pan area lighting lamp selection Everbright shaped or patch shape?

- Patches do some high-end things, large luminous area, from afar to see more clearly, 5-10 meters with patches better!

- Q: How does the LED placement lamp distinguish the positive and negative poles? There is no sign on the light. Thank you

- You can also use the ohmmeter's ohmmeter. To dial multimeter, to "ohm X1" file, the light emitting diode when the red pen is connected to the positive terminal of SMD LED, the black probe is connected to the negative terminal of SMD LED.

- Q: LED light SMD LED package in what form, trouble you under the guidance of...

- The LED chip has bumps and is welded to the PCB board using FLIP CHIP to packaging technology.LED is English light emitting diode (light emitting diode) abbreviation, its basic structure is a electroluminescent semiconductor chip light emitting materials, with silver glue or glue curing to the bracket, connecting a chip and a circuit board and then with silver or gold, then sealed with epoxy resin around, to protect the internal core role finally, the installation shell, so the seismic performance of LED lamp is good. Field of application involves mobile phones, desk lamps, household appliances and other daily household electrical appliances and machinery production.

- Q: Which is good for LED patch and LED bulb?

- LED (light emitting diode) patch (package)LED patch (SMD) made by FPC circuit board, LED, high quality silica gel. The waterproof performance, using low voltage DC power supply is safe and convenient, light colors, bright colors; outdoor use can be anti UV aging, yellowing, high temperature resistance and other advantages, the products are widely used in building lights, decorative lighting, advertising - Entertainment decorative lighting lighting field.LED bulbA solid state semiconductor device that converts electric energy into visible light by means of LED (light-emitting diode), which converts electricity directly into light; LED = Large, Electronic, Display,;

- Q: Patch LED light broken one, short circuit can use it?

- Can not casually short-circuit, according to the LED connection, but also to see the power supply voltage and current, all the LED can not flow. Any short circuit may cause excess LED to flow over or over, causing a chain reaction, a bad string,...... .

- Q: Such as title, please have welding patch LED lamp experience expert guidance, do not search from the Internet to the theoretical knowledge, thank you!

- When soldering, the temperature is best to be lower, and the average welding temperature is about 360. That's enough, because the melting temperature of the tin wire is about 220 degrees, so if it is allowed, the temperature can be reduced as low as possible.

Send your message to us

High Lumen 60-65Lm White SMD LED 5730 For LED Bulb

- Loading Port:

- Shenzhen

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 1 Pc pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords