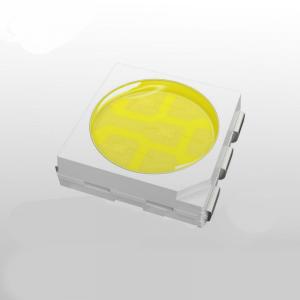

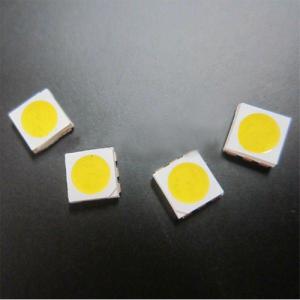

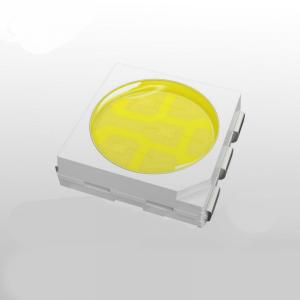

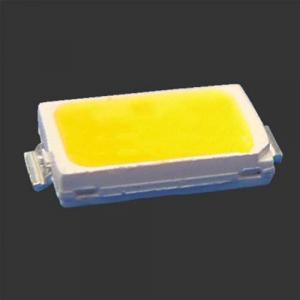

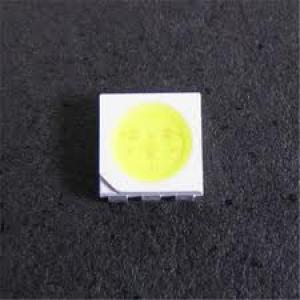

New 5730 SMD Led, 0.5W 5730 SMD Led, 60 Lm 5730 SMD Led

- Loading Port:

- Shanghai

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 3000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction

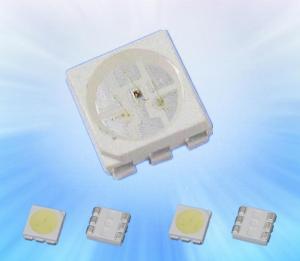

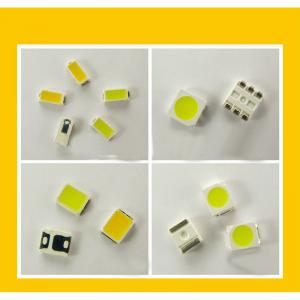

5730 smd led features

Specification

ELECTRICAL/OPTICAL CHARACTERISTICS AT Ta=25°C:

PARAMETER | SYMBOL | TEST CONDITION | Color | MIN | TYP | MAX | UNIT |

Forward Voltage | VF | IF=150mA | White |

3.0

| 3.2 | 3.6 | V |

Reverse Current | IR | VR=5V | White |

|

| 50 | μA |

Peak Emission Wavelength | CT | IF=150mA | White | 6000 | ----- | 6500 | K |

Luminous Intensity | IV | IF=150mA | White | 50 | --- | 60 | LM |

Customized options

Customized label/ Logo can be made onto packing box.

Packaging & Delivery

Package:

1 x Box

Delivery:

Shipping Service | Estimated Delivery Time |

DHL | 2-8 business days |

FedEx | 3-8 business days |

TNT | 2-10 business days |

UPS | 1-7 business days |

EMS | 6-14 business days |

ePacket | 7-12 business days |

China Post Air Mail | 7-15 business days |

China Post SAL | 14-30 business days |

By sea | 30-40 business days |

1. 3-10 business days for Sample Orders; 7-40 business days for Bulk Orders.

2. "Business days" means Monday-Friday, excluding holidays.

3. DHL and UPS cannot ship to military or P.O. boxes address.

4. The Shipping Service above is for reference only, for any other questions, please feel free to contact us.

- Q: What is the difference between SMT LED packaging with silicone and epoxy resin transparent package? What is the market situation of these two types of packaging?

- Epoxy resins turn yellow during short wave irradiation or long periods of high temperature, so they are very short lived when applied to high power lighting. That's why the LED lighting market is dominated by silica gel.But because of the low price of epoxy resin (silica gel and not at a level), and storage, use and processing is superior to silica gel, so the low power LED and some optical components still use epoxy resin package.

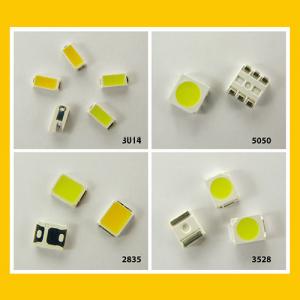

- Q: LED patch lamp band, how to calculate how many watts a meter, such as 3528-60 beads is how much?

- 3528 single lamp is 0.06W 0.06*60 lamp =3.6W 3528-60 bead is 3.6W/ meters

- Q: What should I notice when I want to solder 1206 LED patch type luminous tube on fine copper wire?,

- It is best to use a hot-air gun heat transfer high air volume adjustable low moment welding, the specific heat jump to the appropriate place to see what you use what kind of welding wire, welding wire of different because of the different melting point impurities also some differences. The air volume is too high, easy to blow the original

- Q: What, in what way do I shunt the LED?

- The voltage problem is determined by the size of your POWER SUPPLY, according to Ohm's Law: the series voltage is accumulated and the shunt voltage is the same.

- Q: Is the forward voltage drop of the patch LED too large or too small?

- The pressure drop in the normal range is generally better. The smaller the pressure drop, the lower the power dissipation. The more you save the electricity bill.But not to say that the smaller the better, not in the normal range of low pressure drop products may be defective.In addition, the uniformity of the LED pressure drop is also important.

- Q: What are the storage requirements of SMT patch LED (LED)?

- Keep in storage- the original sealing bag packing in the condition of the <40 C and <90% RH degrees for 12 months, more than the storage period will bake.Please check the leak before opening the packing bagIn opening the sealed bag, should be placed in SMD LED and C 60%RH. < < 30 degrees under the conditions in the above conditions, SMD LED must be in the open package using reflow within 24 hours. If placed more than 24 hours, you need to bake- baked, SMD LED in C + 80 degrees 5 degrees C and <=10%RH relative humidity in the oven for 24 hours? remove the pouch before baking, and do not open the oven door frequently

- Q: Patch LED features

- The seismic resistance, high reliability, low operation cost system.It is easy to small, thin, lightweight, easy to shape without restrictions, made all kinds of application.

- Q: What is the difference in performance between the LED plug-in and the LED patch?

- The cooling of the plug-in is not good, because the plug-in's lamp foot, in order to save costs, generally use iron plus coating, heat conduction is not very good.The strength of aluminium alloy is not enough, it is easy to break, and copper is expensive.Relatively speaking, the patch is good, because the heat is welded on the PCB, copper or direct aluminum substrate cooling, patches near.Otherwise, why do high-power patch it?!SMT direct placement machine, a high degree of automation, low rate of bad.

- Q: Notes on patch LED

- Storage bags are sealed and stored at a temperature of <40 DEG C.

- Q: The ten patch LED lights are connected in parallel. The rated power is 5 watts. How much voltage do you need?

- The voltage needs to be determined according to the product specification, usually 3.1 - 3.5V

Send your message to us

New 5730 SMD Led, 0.5W 5730 SMD Led, 60 Lm 5730 SMD Led

- Loading Port:

- Shanghai

- Payment Terms:

- L/C,T/T

- Min Order Qty:

- 3000 Pcs pc

- Supply Capability:

- 100000 Pcs Per Month pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords