Zircon Brick for Furnaces - High Quality Zircon Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Zircon Refractory Bricks For Furnaces

CMAX Zircon Refractory Bricks are made from chrome and magnesia. Magnesia chrome brick is mainly made from sintered magnesia and chrome-oxide, by high pressure shaping and chrome-oxide,by high pressure shaping and high temperature firing.According to different requirements the contents of the Cr2O3 can be changed. The product has good specifications for the shock resistance and high temperature performance. It's characterized by the small thermal expansion.The good thermal shock resistance and slag resistance.It is widely used for many industrial furnaces and kilns such as cement kilns,open-hearth furnace and melting furnace for nan-ferrous metals.Extra high temperature firing direct bonded,rebounded,rebounded and semirebonded magnesia-chrome brick,which are made from purity material all or part of the material that is synthesizeed through fusion,pressed with fine ingredients and high pressure and sintered by extra high temperature.

Product Applications:

Zircon Refractory Bricks are ideal for use in the below applications

Metallurgy industry of open-hearth furnace top , electric furnace roof, Mixer linings etc.

RH, VOD, AOD, and other refining installations;

Non-ferrous metallurgical furnace, vacuum treatment equipment;

Building materials , glass furnace regenerator; cement rotary kiln calcination etc.

Product Advantages:

CNBM has success in its magnesia chrome bricks due to their cost-effectiveness and excellent insulating properties. The refractoriness of magnesia chrome bricks are more than 2000°C, and the refractory under load is a above 1550°C.Good steady volume in high temperature, the performance of meeting sudden cold and sudden hot is better than magnesia bricks.

Main Product Features:

Low porosity, high compressive strength, flexural strength of high pressure, good bulk stability;

Good thermal shock resistance, anti-spalling

Easy-to-skin hanging in the kiln, and low thermal conductivity;

High temperature of refractoriness under load.

Ultra-high-temperature firing, high direct binding rate, high refractoriness and corrosion resistance.

Strong resistance against alkaline substances, the acid resistance better than the magnesia refractories.

Product Specifications:

Fused-rebonded Magnesia Chrome Brick | |||||||

ITEM | FRMC-12 | FRMC-14 | FRMC-16 | FRMC-18 | FRMC-20 | FRMC-22 | FRMC-26 |

MgO, % ≥ | 68 | 65 | 60 | 58 | 55 | 50 | 45 |

Cr2O3, % ≥ | 12 | 14 | 16 | 18 | 20 | 22 | 26 |

SiO2, % ≤ | 1.2 | 1.4 | 1.4 | 1.5 | 1.5 | 1.5 | 1.5 |

Apparent Porosity, % ≤ | 16 | 16 | 16 | 16 | 16 | 16 | 16 |

Bulk Density, g/cm3 ≥ | 3 | 3.05 | 3.08 | 3.1 | 3.15 | 3.2 | 3.25 |

Cold Crushing Strength, Mpa ≥ | 50 | 50 | 50 | 50 | 50 | 50 | 50 |

Refractoriness Under Load, ℃ ≥ | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 | 1700 |

FAQ:

Q1: Are you a manufacture or trader?

A1: Factory+trade (mainly for manufacturing, also do some business of related products).

Q2: What's the MOQ of trial order?

A2: No limit,We can offer the best suggestions and solutions according to your requirements.

Q3: After an order is confirmed,when to deliver?

A3: According to your order quantity, normally, 15-25 days after deposit received.

Q4: Is your company accept customization?

A4: We have our own factories and excellent technical team, and we accept OEM service.

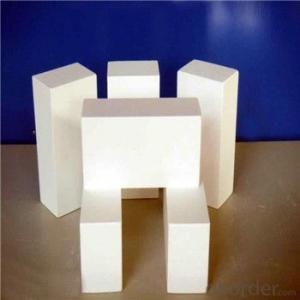

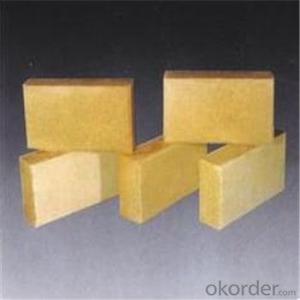

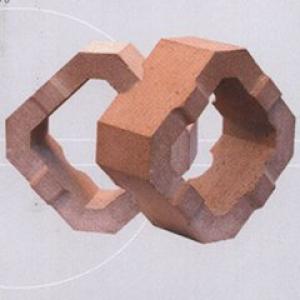

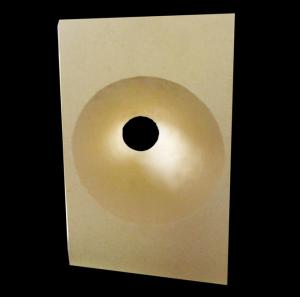

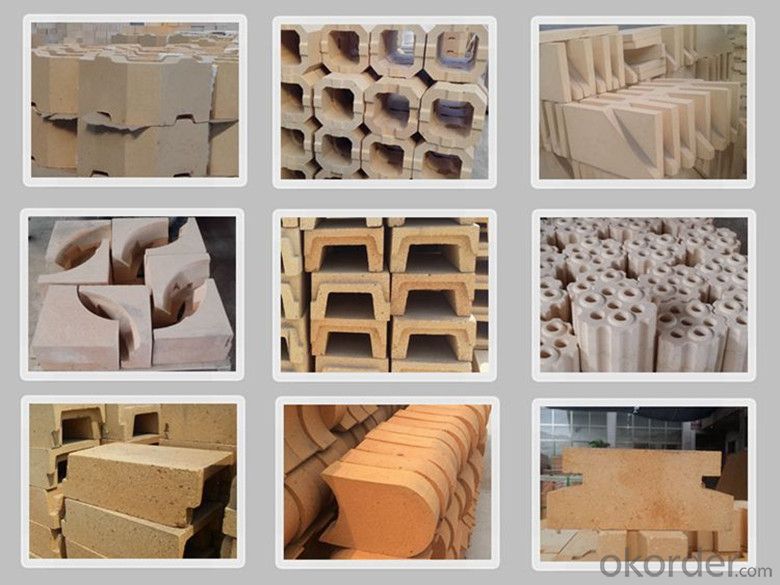

Product Picture

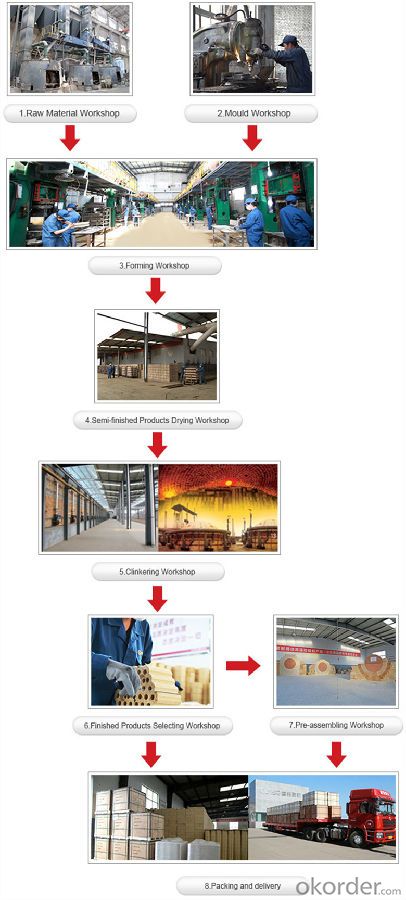

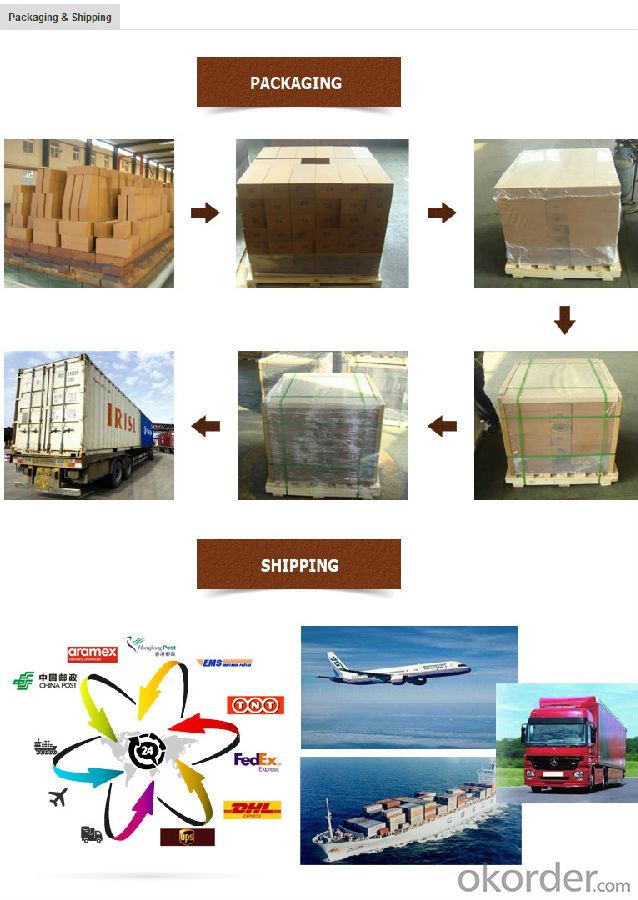

Produce Processing

- Q: What are the ingredients in the binder of the yttrium zirconium brick?

- In the case of adhesive, the normal binder includes the solvent, curing agent, toughening agent, preservative, colorant, defoaming agent and so on.

- Q: What metal materials withstand 1000 degrees high temperature long burning contact with open flame?

- Zirconia brick can withstand 2600 degrees high temperature and good heat insulation performance and long service life

- Q: What's the difference between zirconium and zirconia? What are the fields in which applications?

- Fused zirconia is mainly used for refractory materials, such as zirconia bricks, and used in crystal materials, such as making diamond, and making high-temperature resistant coatings, etc. ~!

- Q: Continuous basalt fiberThere are several questions that we write on paper!Please let me know if you have any information about itHow to choose the heating system for the crucible furnace?The commissioning process of the furnace?

- Generation of platinum crucible and its only bushing connected electrode made of platinum rhodium alloy, and the crucible body and its relevant subsidiary components from refractories and. Liquid glass crucible by molten glass itself as an electrically heating resistor, or by a platinum alloy heater placed in the crucible for heating glass, can also use the resistance heater (with silicon carbide) by radiation heating glass in the glass, the glass liquid reaches the required temperature.

- Q: What is a zirconium drill? Is it valuable?

- Zircon is a natural gemstone in the refractive index after diamond, high dispersion value of the gem, colorless transparent zircon similar to diamond, is a good substitute for diamonds. Commonly used zircon mostly colorless, reddish brown, brown red, green and so on. But the most popular colors are blue and colorless two, in which the blue value is higher, and generally by artificial heat treatment. Many Zircon on the market are sold after heat treatment. This is because the treated stones are prettier and better than the original gemstone.

Send your message to us

Zircon Brick for Furnaces - High Quality Zircon Refractory Bricks

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 pc

- Supply Capability:

- 2000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords