Hot-dip Zinc Aluzinc Coated galvanized steel sheet coil For Metal Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Hot –dip aluzinc steel sheet/coil is substrated on cold rolled steel (CRC) in various strength and specification.

Coating composition is 55% aluminum in weight ratio, 43.4% zinc, and 1.5% silicon, with excellent corrosion and heat resistance performance.

The combination of zinc and aluminum in Galvalume enhances both the positive and negative effects of aluminum.

Galvalume has barrier corrosion resistance and heat resistance similar to aluminized material and good bare edge galvanic protection and forming qualities like galvanized material.

Consequently, Galvalume and Galvalume Plus will resist rust, the elements and fire while providing a sturdy and protective covering.

Standard and Grade :

Hot-dip Aluzinc steel coils | ||||

ASTM A792M-06a | EN10327-2004 | JIS G 3321:2010 | AS- 1397-2001 | |

Commercial quality | CS | DX51D+AZ | SGLCC | G1+AZ |

Structure steel | SS GRADE 230 | S220GD+AZ | SGLC400 | G250+AZ |

SS GRADE 255 | S250GD+AZ | SGLC440 | G300+AZ | |

SS GRADE 275 | S280GD+AZ | SGLC490 | G450+AZ | |

SS GRADE 340 | S320GD+AZ | SGLC570 | G450+AZ | |

SS GRADE 550 | S350GD+AZ | G500+AZ | ||

S550GD+AZ | G550+AZ | |||

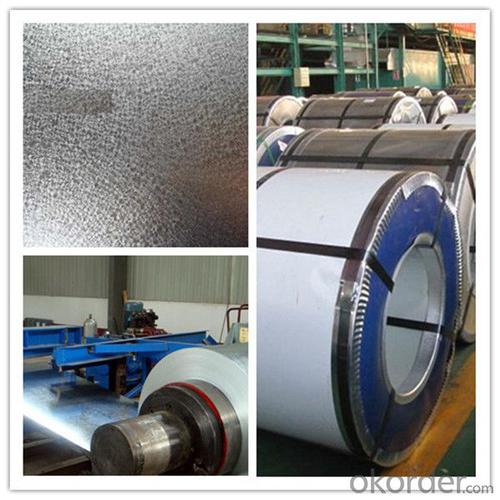

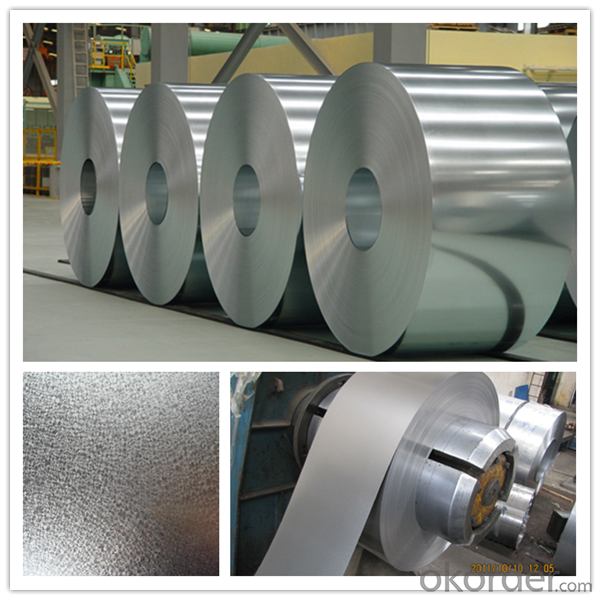

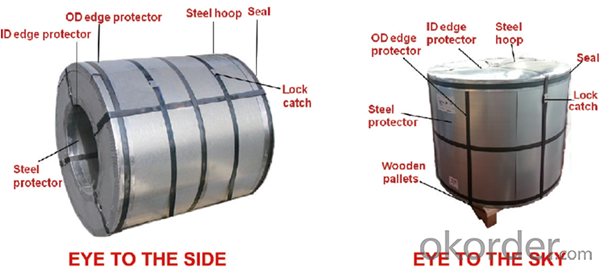

Pictures of Hot-dip Aluzinc steel coils

Application :

Production of cold formed corrugated sheet and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

Packaging & Shipping

Our Advantage

* Professional Personnel of Steel Trading

* Strong Steel Industry Background

* Conveniently Geographic Location

- Q: i always have eaten rolled oats and i have never tried steel cut oats. what are your opinions on them for oatmeal and which do u like better?

- Steel cut oats take very long to cook. They have a bit more bite to them but the flavor is really the same. It's more a question of which texture you prefer.

- Q: How are steel coils used in the manufacturing of railroads?

- Steel coils are used in the manufacturing of railroads to produce rails, which form the tracks that trains run on. These coils are rolled into long, straight sections and then shaped into the required rail profile. The rails are then cut to the desired length and undergo various processes, such as heat treatment and finishing, to enhance their strength and durability. Overall, steel coils are a crucial raw material in the creation of reliable and robust railroad infrastructure.

- Q: Can steel coils be embossed?

- Yes, steel coils can be embossed. Embossing is a process that involves creating raised or indented patterns on a surface, and it can be done on various materials including steel coils. This technique is often used to enhance the aesthetic appeal or provide functional properties to the steel coils.

- Q: How are steel coils inspected for edge quality?

- Steel coils are inspected for edge quality through visual examination, measuring thickness and width, and conducting various tests such as bend tests and surface inspections.

- Q: I was wondering whether anyone knew if painted steels rusts at the same speed as steel that isn't painted. Also, does steel rust quicker than aluminium?Thank you

- Painted Steel

- Q: I'm in the process of buying a new car, and wondering if there are more benefits from Aluminum tire rims over Steel. Aluminum wheels cost more, but you'd think that steel would last longer. Are Aluminum wheels just for looks?

- aluminum is lighter , alot of performance cars use them to trim unsprung weight from the wheels ... steel wheels are cheaper but u have to put hub caps on them ... eeeeeuuuuueeewww!!!!!

- Q: Are steel coils used in the oil and gas industry?

- Yes, steel coils are commonly used in the oil and gas industry for various applications. They are utilized in the manufacturing of pipelines, storage tanks, and other equipment due to their strength, durability, and resistance to corrosion. Steel coils are also employed in the construction of offshore platforms and drilling rigs, where they provide structural support and ensure the safety and reliability of the infrastructure.

- Q: What are chemical properties of high speed steel? Physical properties?What is high speed steel used for? One interesting fact about high speed steel?

- wikipedia: High speed steel (often abbreviated HSS, sometimes HS) is a material usually used in the manufacture of machine tool bits and other cutters. It is often used in power saw blades and drill bits. It is superior to the older high carbon steel tools used extensively through the 1940s in that it can withstand higher temperatures without losing its temper (hardness). This property allows HSS to cut faster than high carbon steel, hence the name high speed steel. At room temperature, in their generally recommended heat treatment, HSS grades generally display high hardness (above HRC60) and a high abrasion resistance (generally linked to tungsten content often used in HSS) compared to common carbon and tool steels. see reference for more info .

- Q: Does steel have a valence number and if so, what is it?

- Steel is a mixture, so it doesn't have any valence number. On the other hand, all of the components of the steel mixture are in their elemental forms, so all the various valences are zero.

- Q: How do steel coil manufacturers minimize waste and maximize efficiency?

- Steel coil manufacturers minimize waste and maximize efficiency by implementing various strategies such as optimizing production processes, recycling and reusing scrap materials, adopting advanced technologies for energy conservation, and implementing lean manufacturing principles to eliminate unnecessary steps and reduce downtime. They also focus on continuous improvement, employee training, and regular maintenance of equipment to ensure smooth operations and minimize waste generation.

Send your message to us

Hot-dip Zinc Aluzinc Coated galvanized steel sheet coil For Metal Roofing

- Loading Port:

- China main port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 17654 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords