Silica Brick for Coke Oven with Zero Thermal Expansion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

General Introduction:

Zero thermal expansion silica brick is also known as fused-quartz brick or thermal shock resistance silica brick.

It has extremely low thermal expansion rate, excellent thermal shock resistance, high SiO2 content etc. Zero thermal expansion silica brick is widely used in hot repair project on coke oven.

By using zero thermal expansion silica brick, the maintenance time for coke oven shortens greatly.

Cunse has the ability on providing the hot repair solution on coke oven, we also can do the EPC project on regular maintenance of coke oven.

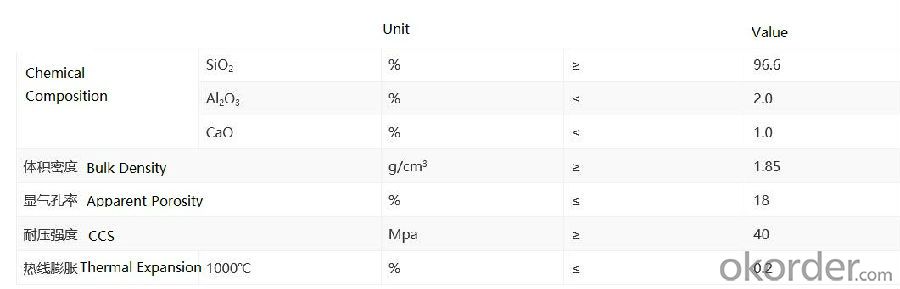

Technical Data:

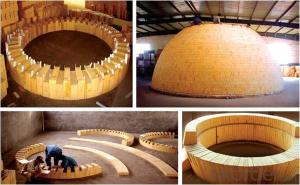

Coke Oven After Repairing

Company Information

CNBM International Corp., established in 2004, is the business entity for international business and logistic of CNBM Group.

CNBM International is highly recognized by its business partners and clients all over the world and has established good business relationship with the customers in over 160 countries and regions all over the world.

FAQ

Q:Are you a trading company or manufacturer?

A:CNBM is a large-scale central governmental industrial group with its own manufacturing sector, research and development sector, trading sector and logistics sector.

Q:I have some special requirement about specifications.

A:We have a well-rounded product range, which endows us with the capability of applying many special specifications. Please feel free to contact us with yours.

Q:Do you accept OEM service?

A:Yes, we do.

Q:What is your delivery time?

A:It depends on the size/complexity of your order and our own production schedule. Usually we provide a faster delivery than the industry's average.

Q:What is the payment term?

A:Our payment terms are negotiable.

Q:Can I have my own logo on the product?

A:Sure, we can apply your own logo on the products according to your drawings.

- Q: The introduction of silica brick

- The characteristics of silica brick:Brick belongs to refractory materials, with strong resistance to acid slag or acid solution erosion ability, high load softening temperature are excellent properties of silica brick, usually 1640-1680 C.The use of silica brick:Mainly used for masonry brick oven carbonization chamber, a combustion chamber and a partition wall, glass furnace and kiln roof, pool wall, high temperature hot blast furnace, glass furnace, load-bearing pool wall, hot blast stove, baking furnace of carbon bearing part of high temperature furnaces etc.. Rongsheng with refractory

- Q: Glass kiln brick for physical and chemical indicators?

- Glass kiln with high quality silica brick products according to the standard JC/T615-1996, the single brick is divided into 3 grades: XBG-96, ZBG-96, DBG-96.

- Q: How to judge the quality of brick, clay brick, high alumina brick furnace from the appearance?

- Mainly depends on the color and density of brick. Another black clay brick and brick with iron oxide formation and how much the size of bricks

- Q: Can iron oxide be used as refractory material?

- Is widely used in this area. Mentioned refractory material of high school textbooks generally refers to three two aluminum oxide (alumina), alumina is also used as a refractory material, refractory crucible, porcelain, artificial gemstones.

- Q: The high thermal conductivity of silica brick and traditional brick what is the difference?

- Tridymite content high thermal conductivity silica brick is 70%, tridymite content of traditional brick is 60%, tridymite content high thermal conductivity of silica brick than tridymite high content of 10% traditional brick,

- Q: Common bond brick?

- Manufacturing for silica brick binder hi-li sulfate pulp waste liquid and lime milk. When lime milk is used as a bond, it acts as a plasticizer. To increase the strength of lime brick in the drying process, as mineralizer in the firing, promote the transformation of quartz.

- Q: How to improve the thermal conductivity of the coke silicabrick rate?

- To improve the thermal conductivity of silica brick for coke oven rate method:Manufacture of high density and high thermal conductivity of silica brick, adding additives such as CuO, Cu2O, TiO2, Fe2O3, (FeO), can improve the thermal conductivity of silica brick.

- Q: Why is the highest brick coke oven temperature measuring point temperature not exceeding 1450

- That is because the brick load softening point the maximum temperature is 1450 degrees.

- Q: What is the silica refractory products?

- High silicon content in high temperature expansion sintering temperature between 1390-1410 in furnace arch

- Q: Why in the production of the brick to detect the volume density

- Density is the property of material, different density of materials, density of the same kind of material is not up to standard, affecting performance.

Send your message to us

Silica Brick for Coke Oven with Zero Thermal Expansion

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 pc

- Supply Capability:

- 1000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords