Z275G Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

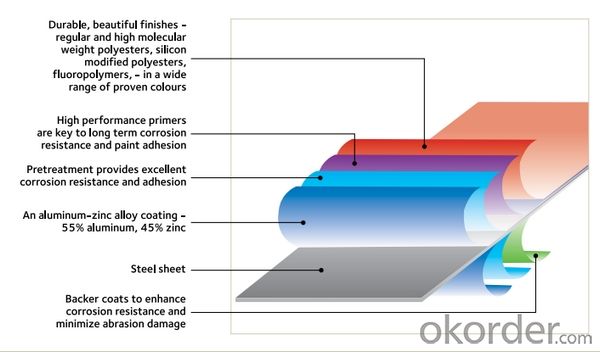

Structure of Z275G Rolled Prepainted Steel Coil for Construction

Description of Z275G Rolled Prepainted Steel Coil for Construction

BMT Prepainted Rolled Steel Coil is a kind of coated steel coil/sheet. PPGL Coil is coated with organic layer, which provides higher anti-corrosion property and a longer lifespan than that of galvanized or galvalume steel sheets. The finish coats of PPGL Coil can be classified into groups as follows: Polyester, silicon modified polyesters, polyvinylidene fluoride, high-durability polyester, etc.

Main Feature of Z275G Rolled Prepainted Steel Coil for Construction

1.Corrosion resistance: It mainly depends on the aluminum protection. When the zinc being worn, the aluminum will form a dense layer of aluminum oxide, resist corrosion material to prevent further corrosion inside.

2. Heat reflective: Galvanized steel plate heat-reflective high rate is twice as galvanized steel, often used to make insulation materials.

3. Economy: Because density of 55% AL-Zn is smaller than the density of Zn, so in the same weight and thickness of Galvanized zinc layer, aluminum-zinc steel plate is larger area more than 3% of galvanized steel sheet.

Applications of Z275G Rolled Prepainted Steel Coil for Construction

1. Construction and building: roofing; ventilating duct; handrail; partition panel

2. Electric appliance: refrigerator; washing machine; refrigerator..

3. Transportation: oil tank; road sign; etc.

4. Agriculture:barn; etc.

5. Others: vending machine; game machine; etc.

Specifications of Z275G Rolled Prepainted Steel Coil for Construction

Product | BMT Prepainted Rolled Steel Coil for Construction |

Material Grade | SGCC / SGCH / DX51D+AZ, etc |

Thickness | 0.18-1.5mm |

Width | 900-1250mm |

Tolerance | Thickness: +/-0.02mm , Width:+/-2mm |

Zinc-coating | Z35-275g/m2 |

Technique | Raw material: Hot rolled steel coil > Cold rolled>hot dipped galvalume |

Surface | Dried, Chromated, Unoiled |

Spangle | Regular spangle , small spangle, zero spangle |

ID | 508MM 610MM |

Coil weight | 3-7MT |

Export package | Cardboard inner sleeves, Waterproof paper, galvanized steel covered and steel strip packed |

FAQ of BMT Rolled Prepainted Steel Coil for Construction

We have organized several common questions for our clients,may help you sincerely:

1. What is your MOQ ?

Our MOQ is 50mt. And there is more discount if you order like 1000 tons and more. The more appropriate payment term your can offer, the better price we can provide.

2. Can you provide the high strength roof sheet/coil?

Yes, G550, with its yield strength over 550 mpa

3. How do you promise the quality of the steels?

We have established the international advanced quality management system ,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

4. What different between PE and PVDF?

PVDF is the most advanced painting in construction industry, it is with high corrosion resistance and color retention, and the life time could last to 20-25 years. Currently, PE is the most widely-used painting in the color coated steel coils. It is characterized by good overall performance, and high economic as well

- Q: so what is stronger tempered steel Blade or carbon steel Blade? a Machete made of those i said above what will last longer,what can cut better,which will will shatter first.

- 1. all steel blades are tempered, whether they are high carbon blades or low carbon blades. 2. It depends on what kind of steel they are made from. So im going to answer this question, using the following qualifications. 440A stainless steel 440C stainless steel - high carbon. The higher the carbon level, the more brittle a blade becomes. But the higher the carbon level, will increase a steel’s wear resistance , meaning it will have a better edge retention 2. They both will work well. Pros's / Con's The 440C blades will need less sharpening, but are harder to sharpen The 4401 blades will need to be sharpened more, but are far easier to resharpen. So it basically comes down to where you will be using them and how you will be using them. If your gonna be out in the middle of the jungle and stopping for the night, then the high carbon blade would probably be better, you use it all day, resharpen it at night. If your gonna be cutting brush, tobbaco, etc on your land, then the 440A would be better, because you can take a couple of min's to resharpen it often

- Q: I asked a question last week about stainless steel and got some great answers. I combed all over the internet to try to figure this one out but could not find anything. What resists bending better: chrome vanadium steel (i.e. a steel commonly used to make tools) or stainless steel 304. My guess would be the chrome vanadium alloy but thats just a guess. Which on resist's bending better and by how much (#'s please :-)). Also, if anyone knows if chrome vanadium steel is cheaper than stainless steel 304 that would be awesome? I can't find a price per pound on chrome vanadium steel anywhere! Please help. Thanks in advance-Josh

- Fill the pot up w/cold water to cover the burned on rice. Bring it up to a boil. Do it again w/some high powered soap in the mix. This time let the water sit in the pan until its luke warm, dump it out and scrub it up w/the plastic scouring pad. You should be all set.

- Q: What are the different types of steel coil coatings?

- There are several different types of steel coil coatings that are used for various purposes. Some of the most common types include: 1. Galvanized Coating: This is a zinc-based coating that provides excellent corrosion resistance to steel coils. It is often used in outdoor applications where the coils are exposed to harsh weather conditions. 2. Galvannealed Coating: Similar to galvanized coating, galvannealed coating also contains zinc, but it is heat-treated to form an alloy with the steel surface. This type of coating provides better paint adhesion and is often used in applications where the coated coils will be painted or further processed. 3. Pre-painted Coating: As the name suggests, pre-painted coatings are applied to steel coils before they are delivered to customers. These coatings can be made of various materials, including polyester, polyurethane, epoxy, or fluoropolymer. Pre-painted coils are commonly used in construction, automotive, and appliance industries. 4. Electro-galvanized Coating: This coating is applied to steel coils through an electroplating process, where a thin layer of zinc is deposited on the surface of the steel. Electro-galvanized coatings provide good corrosion resistance and are often used in indoor applications or where a thinner coating is desired. 5. Aluminized Coating: Aluminized coatings are made by applying a thin layer of aluminum to the surface of steel coils. This type of coating provides excellent heat resistance and is commonly used in exhaust systems, ovens, and other high-temperature applications. 6. Organic Coatings: Organic coatings are typically applied to steel coils to provide additional protection against corrosion and improve aesthetics. These coatings can be in the form of paints, lacquers, or powder coatings, and they can be customized to meet specific requirements in terms of color, gloss, and durability. Overall, the choice of steel coil coating depends on the specific application, environmental conditions, desired aesthetics, and performance requirements.

- Q: How are steel coils welded together?

- Steel coils can be welded together using various methods, depending on the specific requirements and the type of steel being used. One common method is the use of electric resistance welding (ERW), where an electric current is passed through the steel coils to generate heat. This heat melts the edges of the coils, and pressure is applied to join them together. ERW is a quick and cost-effective method for welding steel coils. Another method is high-frequency induction welding (HFIW), which is commonly used for thinner steel coils. In this process, an induction coil is used to generate an alternating magnetic field, which induces an electric current in the steel coils. The resistance of the coils to this electric current generates heat, causing the edges to melt and form a weld. For thicker and heavier steel coils, submerged arc welding (SAW) is often employed. This method involves the use of a granular flux and a continuous electrode, which is fed into the weld area. The flux melts, creating a protective shield for the weld pool, and the electrode melts to form the weld. SAW is a robust and efficient method for welding steel coils. Additionally, laser welding and gas metal arc welding (GMAW) can also be used to weld steel coils. Laser welding offers high precision and speed, while GMAW, also known as MIG welding, uses an electric arc between a consumable wire electrode and the steel coils to create a weld. Regardless of the welding method used, the key factors for successful welding of steel coils are proper preparation of the edges, maintaining the appropriate heat and pressure levels, and ensuring the correct welding technique is employed.

- Q: does anyone out there know where to get a good deal on a pedal steel guitar? i am from northern indiana and i'm willing to travel some if i have to.i am just getting into pedal steel guitar and i really don't have any idea what i need. i don't know how to play a guitar (i do know how to play the piano and the drums) at all but i want to learn to play the pedal stell guitar and i can't do that without getting one first so, if anyone can help me out i would greatly appreciate it! :o)

- Pedal steel guitars are a challenge to learn but they're a great instrument. More, even a starter pedal steel is going to run you $800 or so. Elderly Instruments in Lansing, Michigan sells a Carter brand starter pedal steel for $795 which is about as low as I've seen new ones. It has 3 foot pedals and 4 knee levers so it's nicely equipped. From northern Indiana it's not that far I would think. Good luck.

- Q: How are steel coils used in the production of oil and gas pipelines?

- Steel coils are used in the production of oil and gas pipelines as they are formed into pipes and provide the necessary strength and durability required for transporting these resources over long distances. The coils are uncoiled and then shaped into pipes through a process called pipe forming or rolling, which allows for the creation of seamless or welded pipes depending on the specific requirements. These pipes are then further processed, such as being welded together, coated, or threaded, to ensure their suitability for the transmission of oil and gas. Overall, steel coils play a crucial role in the manufacturing of pipelines by providing the necessary raw material for their construction.

- Q: Cast steel welding

- I Use these for cast iron, www.yms .uk/welding-rod-small-pack/2.5mm-cast-iron-welding-rod-small-pack/1951/11612/detail.asp they are expensive when compared to welding rods for steel but i find that normal steel ones dont work on cast iron

- Q: What are the advantages of using pre-painted steel coils?

- There are several advantages of using pre-painted steel coils. Firstly, they offer a wide range of color options, allowing for greater design flexibility and customization. Secondly, pre-painted steel coils have a protective coating that enhances their durability and resistance to corrosion, extending their lifespan. Additionally, pre-painted steel coils are available in various finishes, such as matte, glossy, or textured, providing aesthetic appeal. Furthermore, these coils are ready for immediate use, saving time and labor costs associated with painting on-site. Overall, pre-painted steel coils offer convenience, durability, versatility, and enhanced aesthetics, making them a preferred choice in various industries.

- Q: How are steel coils processed for galvanizing or coating?

- Steel coils are processed for galvanizing or coating through a series of steps. Firstly, the coils undergo surface preparation, which involves cleaning, degreasing, and removing any rust or mill scale. This is done using chemicals, mechanical methods, or both. Next, the coils are immersed in a zinc bath for galvanizing or passed through a coating application process for other types of coatings. This ensures a uniform and protective layer on the steel surface. Finally, the coated coils are cured or dried using heat or air, after which they are ready for further processing or shipment.

- Q: I am trying to clean up a stainless steel back splash and some kitchen appliances that have brown spots that look like rust spots. I was able to remove most of them with stainless steel cleaner but does anyone know any tricks?

- if okorder /

Send your message to us

Z275G Rolled Prepainted Steel Coil for Construction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 30000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords