Z1J-SG-1002 Impact Drill

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

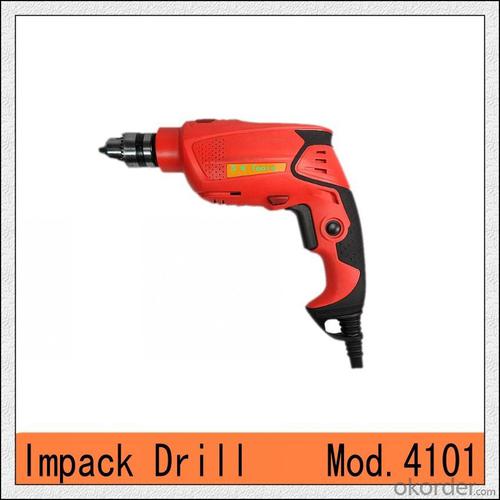

You Might Also Like

Type: Impact Drill Model : Z1J-SG-13

No-load speed : 0-3000 (r / min) hole diameter : 13mm Power Type: AC

No-load speed : 0-3000 (r / min) hole diameter : 13mm Power Type: AC

Power supply voltage : 220V Rated output power : 550 (W) Rated speed : 0-3000 (r / min)

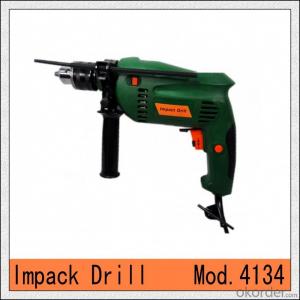

Basic technical parameters

Standard models : Z1J-SG-10 Order number : 41002

Voltage : 110V / 220V Frequency : 50 / 60Hz

Rated speed : 0-3000r / min Drilling Direct : 10mm

Motor : 30mm casing colors: Bosch Blue ( 500 or more can be customized)

Packaging: carton packaging accessories: drill chuck key , manual

Packing Size : 50X40X30 Number of units : 10 units / piece 14KG / 16KG

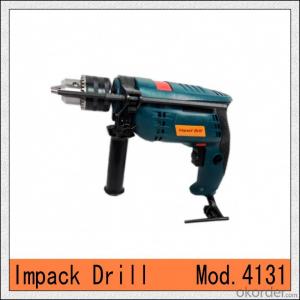

Standard models : Z1J-SG-10 Order number : 41002

Voltage : 110V / 220V Frequency : 50 / 60Hz

Rated speed : 0-3000r / min Drilling Direct : 10mm

Rated power : 500W

Motor : 30mm casing colors: Bosch Blue ( 500 or more can be customized)

Packaging: carton packaging accessories: drill chuck key , manual

Packing Size : 50X40X30 Number of units : 10 units / piece 14KG / 16KG

- Q: Why do electric drills use brush motors?

- Start J torque and strong overload capacity single-phase series motor starting torque is large, 12000 R / mln motor starting torque of up to 4 to 6 times the rated torque of AC motor, and the other is 1 times the most single-phase so it is applicable to electric overload capacity, also suitable for heavy load.

- Q: Is it easy to consult an electric drill?

- A tapping hand drill, the early start is not easy, we must first need to have a 1. speed and reversing the electric drill, the bottom 2. is slightly larger than the manual, 3. volume efficiency, 4. general material is relatively thin (shallow tapping) 5. material hardness, 6. skilled degree. To sum up, it is not very convenient, (if it is self tapping screws or more convenient), the amount of small, use manual bar

- Q: How does electric drill leakage repair? What are the problems of electric power in front of drill bits?

- If you are using an impact drill, it is generally suspected that the insulation pipe of the motor rotor is subjected to high voltage breakdown or breakage.An insulating tube is placed on the rotor shaft of the motor rotor, then pressed on the silicon steel sheet and then wrapped around the enameled wire. Thus, the rotating shaft of the motor is insulated from the energized part. If the insulating pipe is damaged, the current is transmitted from the shaft to the holder, which is very dangerous, and is suggested to be replaced immediately.

- Q: An electric drill has direct current and alternating current. What advantages and disadvantages do they have? Which is better in routine maintenance?

- Mainly power and portability are different, all need carbon brush, so almost the other.

- Q: What's the difference between an impact drill and an ordinary electric drill?

- The percussive drill works by rotating and impacting and can be used for natural stones or concrete. Impact drill work in a drill chuck adjustment knob, adjustable normal electric drills and impact drills in two ways. But the impact of drilling is the use of internal gear to achieve mutual beat of impact, the impact force is far less than the hammer.

- Q: On a bench drill and drill power question

- Different types of motor structure vary greatly, the drill is ordinary mussaurus AC asynchronous motor, it has very few, have a fixed speed;

- Q: How to detect the short circuit of an electric motor stator?

- You unpack the rotor, the stator of single power supply, for the moment, a long time will burn the coil, you do not know what type of motor has no capacitor, if found stator coil line is relatively new, generally not short. Or look at the capacitor, wiring is a problem.

- Q: What is a brush drill, what is a brushless electric drill, what is the difference?

- First of all, the cost problem, brushless motor drive device is very expensive (brushless motor itself is cheap), electric adjustment + motor one hundred to hundreds of pieces uncertain.Now, the AC excitation motor used by the electric drill doesn't use any microelectronic chip. It only uses copper wire and silicon steel sheet, which is very cheap.

- Q: BOSCH BOSCH electric drill can distribution when grinding head grinders?

- Of course, if you still use the same type of electric drill after modification, it belongs to intermittent use. That's ok. As for what kind of grinding head, as long as the size of the right, but also do not allow the motor to bear the burden on it.

- Q: What size is the drill bit used to install the ceiling drill?

- The basic requirement of lamp installation is that it must be firm. Installation of various types of lamps should be installed according to the requirements of lighting installation. If the weight of the lamp is greater than 3kg, the embedded hook shall be used or the hanger shall be fixed directly from the roof with expansion bolts.

Send your message to us

Z1J-SG-1002 Impact Drill

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords