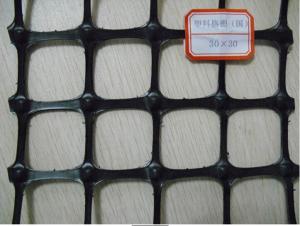

Woven Polyester Geogrids Geocomposite Geomembrane for Rock Fill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

The description of Geocomposite Geomembrane for Rock fill dam and transportation tunnel

Made by non woven geotextile and PE/PVC geomembrane. Categories are including geotextile and geomembrane, geomembrane with non woven geotextile on both sides, non woven geotex-tile with geomembrane on both sides, multi-layer geotextile and geomembrane.

Specification of eocomposite Geomembrane for Rock fill dam and transportation tunnel:

L. One geotextile and one geotextile, geotextile: 100 - 800g/m', geomembrane O. 1-I. Omm.

2. Geomembrane with geotextile on both sides: Geotextile 100 - 400G/M2; Geomembrane: 0.2 - l. Omm

3. Geotextile with geomembrane on both sides: Geotextile 100 - 800G/M2; Geomembrane: 0.1- 0.8mm

Features or Property of Geocomposite Geomembrane for Rock fill dam and transportation tunnel:

L. Good flexibility

2. Separation, reinforcement and protection

3. Waterproofing

Application of Geocomposite Geomembrane for Rock fill dam and transportation tunnel:

L. Reinforcement in channel

2. Embankment, reservoir

3. Waterproofing in reservoir

4. Rock fill dam and transportation tunnel

Production Standard of Geocomposite Geomembrane for Rock fill dam and transportation tunnel:

GB/T17642-2008

Area |

|

Hydraulic | Lagooning and Water Treatment, Ornamental Ponds, Golf Courses Aquaculture and Desalination Water LagoonsTanks, Reservoirs, Liquid WasteFloating Cover SolutionsDrainage and FiltrationShading Cover Solutions |

Environment | Tailing ponds, Leach mining,Landfills,Landfill Capping,Protection against corrosion,Vertical Barriers |

- Q: How much is the tensile strength of geogrid???????

- Whole plastic stretch type: two-way products: 15KN--50KN one-way products: 50KN---300KN

- Q: History of geotechnical materials

- Geosynthetics are widely used in geotechnical engineering at present, which is a general name of polymer products. As early as in 1920s, the chemical industry was successful in the production of synthetic materials, but it was not until the late 50s that the material was gradually used as a new type of building materials to be used in geotechnical engineering. In the early stage, the products were mainly pervious to spinning and non-woven geotextiles, and later produced impermeable geomembrane. With the requirement of engineering practice and the improvement of manufacturing technology, the geogrid and other composite products with high strength reinforcement are manufactured. In this way, the original geotechnical fabric word has not summarized all kinds of products in the international meaning, so there are many alternative names, the geotextile material was the most common, but the habit still referred to as geotextile. Geotechnical material is divided into several categories of materials: geotextile, geomembrane, geogrid, drainage board, composite geomembrane, geotextile, geocell, bentonite waterproof blanket, etc..

- Q: What is the difference between a woven and a non-woven geogrid?

- A woven geogrid is made by weaving polyester or polypropylene yarns together, creating a strong and stable grid structure. On the other hand, a non-woven geogrid is made by bonding polyester or polypropylene fibers together, forming a random network of filaments. This results in different characteristics and performance. Woven geogrids typically have higher tensile strength and are more rigid, making them suitable for applications requiring load distribution and soil reinforcement. Non-woven geogrids, while generally having lower tensile strength, offer excellent filtration and separation capabilities, making them ideal for erosion control, drainage, and subgrade stabilization.

- Q: How do geogrids compare to other soil reinforcement methods?

- Geogrids are a highly effective soil reinforcement method that offers several advantages over other techniques. Unlike traditional methods like retaining walls or soil nails, geogrids are lightweight and easy to install, making them a cost-effective solution. Geogrids also provide excellent tensile strength and stability, increasing the load-bearing capacity of soil and preventing erosion. Additionally, geogrids are flexible and adaptable, allowing for better distribution of load and accommodating ground movements. Overall, geogrids are a superior choice for soil reinforcement due to their versatility, durability, and cost-efficiency.

- Q: Classification and application of polyethylene geogrid?

- The utility model is suitable for the construction of roads, railways, rivers, lakes, and coastal areas, such as reinforced retaining walls, dams, bridge decks, steep slopes and geocell. Its function is to improve the bearing capacity of the retaining wall or embankment, prolong the service life, reduce the occupation area, shorten the construction period, reduce the cost and reduce the maintenance cost.

- Q: Can geogrids be used in shoreline erosion control?

- Yes, geogrids can be used in shoreline erosion control. Geogrids are commonly utilized in shoreline stabilization projects to reinforce and stabilize the soil, preventing erosion caused by waves, currents, and other environmental factors. They are effective in providing long-term erosion control by distributing loads and preventing soil movement, making them a suitable solution for shoreline protection.

- Q: Can geogrids be used in retaining wall construction?

- Yes, geogrids can be used in retaining wall construction. Geogrids are commonly used as a reinforcement material in retaining walls to enhance stability, prevent soil erosion, and increase load-bearing capacity. They are typically installed horizontally within the soil layers of the retaining wall structure to distribute the forces exerted by the retained soil.

- Q: Can geogrids be used in retaining walls for highway sound barriers?

- Yes, geogrids can be used in retaining walls for highway sound barriers. Geogrids are commonly used in retaining walls to reinforce the soil and provide stability. They can enhance the structural integrity of the retaining wall and help it withstand the lateral pressure exerted by the soil. Additionally, geogrids can also improve the overall performance of sound barriers by reducing noise transmission through the wall.

- Q: Steel wire mesh is a kind of geotechnical material

- The total area of the grille rib, rib steel wire grid as much as possible is less than the opening area, in order to ensure the mechanical occlusion compared with the interlocking effect. That is to say, to make the mesh as much as possible to bite the soil area, in order to give full play to the role of occlusion. But the mesh size should not be too large, otherwise the stiffness of rib is small, but the bite force decreased. Three. The ribs and ribs of the grid should be perpendicular to each other so as to transfer the load more effectively. If both are not vertical...

- Q: Biaxial tension geogrid

- Here you want to see what the specifications, different specifications of different weight,

Send your message to us

Woven Polyester Geogrids Geocomposite Geomembrane for Rock Fill

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords