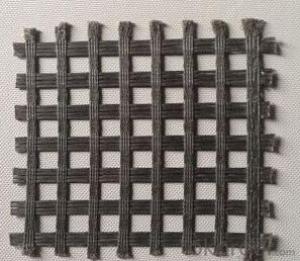

Polymer Geogrids Reinforced Nonwoven Geotextiles in Civil Engineering Composite Geotextile with Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

1) Weight:100gsm-1500gsm

2) width:Within 8m

3)le

composite geotextile with membrane,nonwoven Geotextiles In Civil Engineering

Product Description

Geotextiles also called geotextile fabrics, it’s permeable geosynthetics made of synthetic fibers through woven or needle punched.

Geotextiles including :needle punched nonwoven geotextile , filament woven geotextile , split yarm PP woven geotextile,composite geotextile + geomembrane,Geotextile Bags.

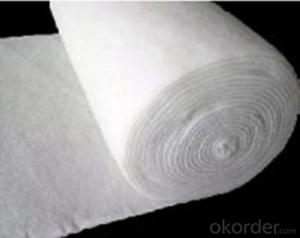

1) Staple fibers needle punched non woven geotextile

The geotextile is made of polypropylene staple fibers on cross-laying equipment and needle punched equipment.

It owns the advantages of acid and alkali resistance, erosion resistance, aging resistance, large strength, stable size, good filtrability etc.

2 ) Filament non woven geotextile

Filament geotextile has features as follows: High strength, good capacity of elongation and high biology tolerance, alkali tolerance, acidity tolerance, weather resistance good filtration and fine drainage capacity etc. Also it is of low cost, easy in construction and use effects.

3) Geotextile membrane:

1. One piece of geotextile and one piece of membrance :Wight:100~1000/m2 , Thickness : 0.1~1.5mm

2. Two piece of geotextile and one piece of membrance :Wight:80~600/m2 , Thickness : 0.2~1.5mm

3. One piece of geotextile and two piece of membrance : Wight:100~1000/m2 , Thickness : 0.1~0.8mm

4. multi-layers :Wight:100~1000/m2 , Thickness : 0.1~0.8mm

Flexibility is good,except of geotextile's isolation,drainage, reinforcement,protective functions,It is also impermeable.

Usage: Widely used in dam,traffic tunnel,road,airport,drainage,housing,environmental protection and other fields for waterproof protection,reinforcement etc.

- Q: What are the benefits of using geogrids in retaining walls?

- The benefits of using geogrids in retaining walls include increased stability, improved load-bearing capacity, reduced soil erosion, and longevity of the structure. Geogrids reinforce the soil, preventing it from sliding or collapsing under pressure, making the retaining wall more durable and resilient. Additionally, geogrids distribute the loads evenly, reducing the risk of settlement and enhancing the overall performance of the wall. They also enhance drainage and filtration, minimizing water buildup behind the wall and preventing soil erosion. Overall, geogrids help to ensure the longevity and effectiveness of retaining walls.

- Q: The effect of steel and plastic grille in steel and plastic grille

- 1 plastic steel plastic grille used to increase the bearing capacity of the road (ground), Yan Changlu (ground) based service life.2 plastic steel plastic grille used to prevent road (ground) surface collapse or crack, keep the ground beautiful and tidy.

- Q: Can geogrids be used in erosion control blankets?

- Yes, geogrids can be used in erosion control blankets. Geogrids are commonly used as reinforcement materials in erosion control applications to provide additional strength and stability to the blanket, preventing soil erosion and promoting vegetative growth.

- Q: Classification and application of polyethylene geogrid?

- A grille is made of polypropylene, PVC polymer and thermoplastic or molded by two-dimensional grid or a certain height of the three-dimensional mesh screen, when used as a civil engineering, called geogrid

- Q: How do geogrids enhance the stability of steep slopes?

- Geogrids enhance the stability of steep slopes by providing reinforcement and confinement to the soil. They are typically installed within the slope, creating a strong interlocking network that distributes loads and prevents soil movement. This reinforcement helps to increase the overall strength of the slope, reducing the risk of slope failure and improving stability.

- Q: What way to quickly cut the geogrid

- Unidirectional geogrid, 1 unidirectional Geogrid Reinforced Soft Foundation: Geogrid can rapidly improve the bearing capacity of the foundation and development of settlement control, can effectively load to the base of a wider upper limit on the road side, thereby reducing the base thickness, reduce project cost, shorten the construction period, prolong the service life.2, check the geogrid reinforced asphalt pavement or cement: Geogrid laying layer at the bottom of asphalt or cement, can reduce rutting depth, prolong the fatigue life of the pavement, but also can reduce the asphalt or cement pavement thickness, in order to save costs.

- Q: Can geogrids be used in soil reinforcement for pipeline projects?

- Yes, geogrids can be used in soil reinforcement for pipeline projects. Geogrids provide stability and enhance the load-bearing capacity of soil, making them effective in preventing soil erosion and maintaining the integrity of pipelines. They are commonly used to reinforce weak or unstable soils, improving the overall performance and longevity of pipeline projects.

- Q: Can geogrids be used in reinforced earth bridge abutments in liquefaction-prone areas?

- Yes, geogrids can be used in reinforced earth bridge abutments in liquefaction-prone areas. Geogrids are often used in such areas to provide additional stability and to mitigate the effects of liquefaction. They help distribute loads and reinforce the soil, reducing the risk of settlement or failure during liquefaction events.

- Q: How do geogrids help in reducing the environmental impact of construction?

- Geogrids help in reducing the environmental impact of construction by providing soil stabilization and reinforcement, reducing the need for excessive excavation and material usage. This results in minimized disturbance to natural habitats, reduced waste generation, and lower carbon emissions, ultimately promoting sustainable construction practices.

- Q: Are geogrids suitable for use in sports field construction?

- Yes, geogrids are suitable for use in sports field construction. Geogrids provide excellent soil stabilization, reinforcement, and drainage properties, which are essential for maintaining the durability and stability of sports fields. They help prevent soil erosion, improve load-bearing capacity, and enhance the overall performance of the field, making geogrids a reliable choice for sports field construction.

Send your message to us

Polymer Geogrids Reinforced Nonwoven Geotextiles in Civil Engineering Composite Geotextile with Membrane

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords