Wood Plastic Composite Flooring Use for Dustbin

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

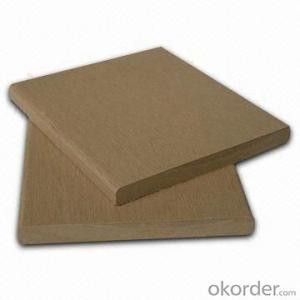

Introduction of Wood Plastic Composite Flooring Use for Landscape

A safe, environmentally responsible alternative to traditional decks, conserving energy and resources. Not only does this save your time over the maintenance, but it will save you money as well.

Composition of Wood Plastic Composite Flooring Use for Landscape

30% HDPE+60% bamboo/wood fiber+10% Chemical additives.

Advantage of Wood Plastic Composite Flooring Use for Landscape

· Maximum length: 6m

· UV resistance, durable

· Safe, environmentally responsible alternative to traditional decks, conserving energy and resources

· Low maintenance

· 100% recyclable

· Saves forest resources

· With look of natural wood but no timber problems

· Moisture/water-resistant

· No rotten, proven under salt water condition

· Barefoot friendly, anti-slip, no cracking and warping

· Requires no painting and glue

· Weather-resistant

· Termites, insects and moldy-proof

· Easy to install and clean

· Available in various colors

· Can be used in Temperature: -40 to +60°C

Installation of Wood Plastic Composite Flooring Use for Landscape

Correct installation needs your high attention!

1 Always leave space (5-7mm) between 2 boards, or between board and wall.

2 Where there are 2 board ends meet, put 2 pcs of keels under each board end.

3 Keep the space of 2 keels at 25-750px.

4 Do not use glue to install.

5 Do not use our product where is always wet and sunless.

Other Information of Wood Plastic Composite Flooring Use for Landscape

HS code: 3918909000

Time for production(1x20fcl): 15 days

Warranty: 10 years.

Certificate: CE, ISO

- Q: Performance requirements for plastic flooring

- Water resistance. Resistance to washing, no deformation, loss of light, fading, etc..4, dimensional stability. The size of the bulk floor has strict requirements.

- Q: EVA plastic floor and PVC plastic floor which is good

- PVC: is stable; it is not easy to be corroded by acid and alkali.

- Q: Plastic floor gap can be used to do plastic glass

- Hello landlord! Select the plastic floor must choose the site dedicated, the wrong choice of use and material life, you know! There are many types of plastic floor, mainly divided into coil and sheet, is the most common material, plastic sheet flooring series of thousands of species, like the current popular commercial floor: PVC floor (such as shopping mall (supermarket), hotel, hotel, hospital, school, kindergarten, family, office, commercial airport... Site

- Q: How to tear off the plastic film on the floor tiles

- If it is anti fouling wax, live for a few days did not, and would like to remove a one-time use of fly powder (dry), with a dry cloth can be wiped directly.

- Q: PVC plastic floor defects

- PVC, also known as polyvinyl chlorideAdvantages: corrosion resistance! Good tensile strength; compressive strength!Disadvantages: poor ventilation; flexible than other plastics; quality is not good PVC also has a small amount of toxicity; at low temperature is more brittle; smell is relatively large!Uses: agricultural water supply and drainage, irrigation, rainwater pipes, exhaust pipes, wire conduits, industrial anti-corrosion pipe, toys, stationery, plastic flooring, etc..

- Q: What is the difference between PVC plastic floor and composite floor?

- The appearance of solid wood composite floor with the same wood flooring with beautiful wood texture, good dimensional stability, easy installation and maintenance. But still can not get rid of the fear of fire, fear of water, fear of the shortcomings of the tide, it is not as good as PVC floor environmental protection, wear resistance is not as good as PVC floor.

- Q: There is a layer of plastic on the floor of the room

- The ground cushion treasure is a new type of lightweight sheet made of polystyrene resin and other additives. The utility model has a continuous uniform and dense surface layer and a closed cell structure, and the wall of the honeycomb structure has the same thickness. Therefore, the utility model has the advantages of superior thermal insulation performance, good moisture resistance, long durability, high compression resistance and good sound insulation effect. And it is non-toxic environmentally friendly products.

- Q: 2mm thick PVC plastic floor is generally one square meter

- The answer is not unique.PVC floor coil and blocks, and the wear layer thickness is not the same. Weight is not necessarily the same.I specialize in Bonie PVC flooring.Generally 1KG per square meter

- Q: What is the material of the plastic foam plate

- PVC soft material floor soft PVC roll floor general use calendering production. Among them, the filler is less and the plasticizer is more than PVC

- Q: What are the hazards of plastic floor?

- The utility model relates to a plastic floor leather, which belongs to the soft floor, which is made of polyvinyl chloride resin as the main raw material, and is added with appropriate auxiliary agent

Send your message to us

Wood Plastic Composite Flooring Use for Dustbin

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords