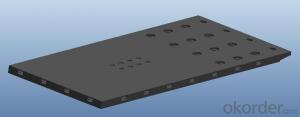

Wood plastic building templates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Wood plastic building templates

Wood plastic building template is to replace the steel templates and bamboo glue board new template. With light weight, impact strength is big, easy to assemble, high turnover rate, smooth surface, no moisture absorption, no mildew, acid and alkali resistance, no crack, board of big, less seams, sawing, can be nailed, can be processed into any length, and many other advantages. Can be recycled repeatedly, the price is much lower than the current use of bamboo template construction, and it has excellent flame retardant performance, from self-extinguishing fire, smoke-free, no gas. Is a new generation of safe green energy-saving products.

Related regulations standard:In accordance with the national standard GB/T29500-2013

Specifications: 50 per pack

Each size :1830*915*15mm

Color: Light green

Weight : 17.5 kg

The main raw material:

Wood plastic, or wood plastic composite, is booming inrecent years a new type of composite material at home and abroad, the use ofpolyethylene, polypropylene and PVC, etc., instead of the usual resin adhesive,with more than 35% to more than 70% of the wood powder, rice husk, straw wasteplant fiber blend into a new wooden material, then through extrusion, plasticmold, injection molding processing, production of the sheet or shaped. Mainlyused in building materials, furniture, logistics packaging, etc. Plastic andwood powder mixed in certain proportion after hot extrusion forming of plank,called extrusion wood plastic composite plate.

Wood plastic template product energy-saving advantages:

1, wood and plastic sheet can be instead of wood, the protection of forest resources;

2, wood and plastic sheets available plant straw, reduce environmental pollution;

3, wood and plastic sheet can eliminate the white pollution, beautify the environment.

Ten advantages of material:

(1) waterproof,moistureproof. Fundamentally solved the wooden products after absorbing waterbe affected with damp be affected with damp in damp and much water environmentare easy to corrupt, expansion deformation problem, can be used to theenvironment of traditional wood products cannot be applied.

(2) theinsect-resistant, termite resistance, effectively prevent insect harassment,prolong service life.

(3)colorful, many colors available. Both have natural woodiness feeling and woodtexture, and can according to your own personality to customize the color youneed

(4)plasticity, can be very simple to realize personalized modelling, reflectindividual character style adequately.

(5) highenvironmental protection, pollution-free, pollution-free, recyclable. Productdoes not contain benzene, formaldehyde content is 0.2, below EO level standard,for the European environmental protection standard of grading, recycled greatlysave the wood use, suitable for the sustainable development of the nationalpolicy, the benefit of society.

(6) highfire resistance. Effective flame retardant, fire rating to achieve B1 level, inself-extinguishing fire, do not produce any toxic gases.

(7) goodmachinability, available, planing, sawing, drilling, surface can be painted.

- Q:Shear wall plastic template for the wall height and thick ratio requirements is how much?

- The support system of the building template should be able to maintain the safety and reliability of the vertical placement of the building template and its own stability under the wind load. The length of the foot adjustment bolt should meet the need to adjust the vertical installation of the template and adjust the self-stabilizing angle. The foot adjustment device should be easy to adjust and turn flexible. Panel should be used not less than 5mm thickness of the production of steel, the material should not be lower than the performance requirements of Q215A, the template of the ribs and back corure should use steel, cold-formed thin-walled steel production, material and steel panel material should be the same brand to ensure Welding performance and structural properties. Panel system, support system, operating platform system and connectors and other components. Composition of the building template The connection between the various systems must be safe and reliable.

- Q:Plastic building template made of what material

- Building template is generally wood template, steel formwork, plastic template (also can be said that the composite template), steel plate high strength, can be reused many times

- Q:I am a novice, do this product development, and now design a set of products, and now take the product to open the mold, it is not clear what kind of material template selection! Please advise experts who look

- You do not explain your product is to open a metal mold or plastic mold, the two mold materials are not the same! I do plastic mold, we mainly use the factory S136 quenching material as a mold material, the slider generally use 718. And you also have the output of the product requirements of the mold, the production will choose a better point of the material.

- Q:Plastic mold dynamic template, the size of the template

- A lot of it? What are you talking about? Plastic mold points a lot of tonnage, there are 80T, 120T, 240T, 1000T, 1250T

- Q:Want to purchase a number of building templates and found a new plastic building template, do not know how the quality?

- Plastic construction template is the disadvantage of airtight and non-absorbent, in the mold, the wall will blister, can not meet the construction requirements, especially high-rise buildings, repeated use after a few times can no longer use. At present, a large number of domestic or wood template.

- Q:Will the plastic building template on the builders really do not use the price is how much price

- Easy to use, heat insulation. A lot of building materials market there ah, to see what you want the model, the price range,

- Q:Europe and the United States national construction template is made of plastic or wood

- Although the problem is not understand the landlord can not help.

- Q:Does the building plastic template use it? How's the effect? Can I use 30 to 50 times? Can the fire protection requirements of the steel plate on the cast-in-place plate be achieved?

- I used, hand drawing is very convenient, can use hundreds of times, made of plastic

- Q:Plastic construction template has no one used? How about the effect of using. How much can the main savings? Can really use 50 times?

- By our site identification: hollow plastic building templates to protect the case of the use of 50 times is not a problem, even more than 50 times. Not capped Plastic non-stick cement. You know.

- Q:Who used it, how not universal.

- 4. The product pouring concrete surface smooth, bright as a mirror, to meet the requirements of decorative and decorative water, eliminating the need for secondary plastering process. 5. Turnover times more than 50 times, the template each time the amortization cost is less than 3 yuan, steel frame plastic template turnover times more than 300 6. The material is non-toxic, harmless, pollution-free, 100% recovery, green products The 7. The product acid, alkali, anti-corrosion performance. Product use temperature of -80 ℃ ~ 100 ℃, good weather resistance.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wood plastic building templates

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Related keywords