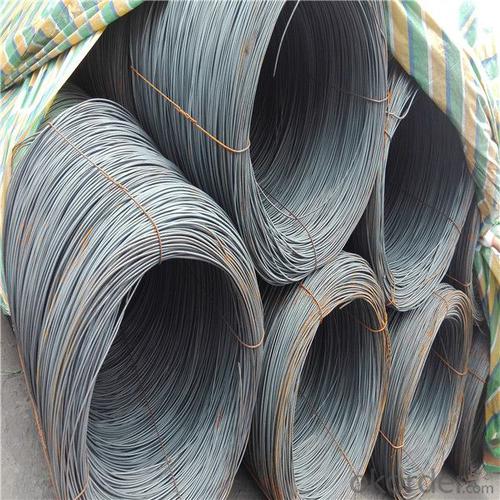

Wire rod with hot price 5.5mm-12mm different grade

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 19710 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Produced from billets at the rolling mill, wire rod is the basis of all steel wire, rope and fencing products.

The most important characteristic in determining wire rod’s end use is its drawability. Common low carbon

wire rod is used for nails, small shaped products, barbed wires, various wire nettings, steel chains, and other

applications. High Carbon wire rod uses include steel tire cords for automobiles, conveyor belts, and pressure

hoses. Other applications include bolts, nuts, and machine parts, as well as compression, tension and torsion

springs

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make

for wire mesh.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

FAQ:

1.Q:Can you accept mixed order?

A: Yes, mixed acceptable .

2. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

3. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

4. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How is steel wire rod classified based on its end-use applications?

- Various categories exist for the classification of steel wire rod based on its end-use applications. One commonly used classification system is based on the intended wire production. For instance, there are wire rods specifically manufactured for construction purposes, such as reinforcing concrete structures or creating fences. These wire rods possess specific mechanical properties and are often corrosion-resistant to ensure durability in harsh environments. Another classification system is based on the wire rod's application in the automotive industry. Steel wire rods used for manufacturing automobile components, like springs, suspension systems, or seat frames, have different requirements in terms of strength, ductility, and fatigue resistance. Consequently, they are produced with specific chemical compositions and undergo specialized heat treatments to meet these demanding requirements. Furthermore, steel wire rod can be classified based on its application in the manufacturing of electrical wires and cables. These wire rods are designed to have exceptional conductivity properties and are frequently made from specific alloys, such as aluminum or copper-clad steel, to optimize electrical performance. Moreover, steel wire rods can also be classified according to their end-use applications in the manufacturing of various consumer goods. This encompasses wire rods used for producing wire ropes, nails, screws, bolts, and other fasteners. Depending on the intended use of the final product, these wire rods need to possess high tensile strength, good formability, and resistance to corrosion. In summary, the classification of steel wire rod is based on its end-use applications to ensure that it meets the specific requirements and performance expectations of various industries.

- Q: How is steel wire rod used in the manufacturing of wire for shopping baskets?

- Steel wire rod is an essential component in the manufacturing of wire for shopping baskets. It serves as the raw material that is transformed into wire through a series of manufacturing processes. The steel wire rod is first heated and then passed through a series of rollers to gradually reduce its thickness and increase its length. This process is known as drawing and it helps to improve the tensile strength and flexibility of the wire. Once the wire is drawn, it is typically coated with a protective layer to prevent corrosion and enhance its durability. This coating can be made of materials such as zinc or plastic. The coated wire is then shaped into the desired form, which in the case of shopping baskets, is usually a mesh-like structure. This shaping is done through a process called welding, where the wire is bent and joined at specific points to form the basket shape. The steel wire rod used in the manufacturing of wire for shopping baskets is chosen for its strength, resilience, and ability to withstand heavy loads. It ensures that the shopping baskets are sturdy enough to carry various items without bending or breaking. Additionally, the steel wire rod's corrosion resistance properties ensure that the wire and ultimately the shopping baskets have a longer lifespan, even when exposed to moisture or harsh environments. In summary, steel wire rod plays a crucial role in the manufacturing of wire for shopping baskets. It provides the raw material needed to produce the wire, which is then coated, shaped, and welded to create the final product. The strength, resilience, and corrosion resistance of the steel wire rod ensure that the shopping baskets are durable, long-lasting, and capable of withstanding the demands of everyday use.

- Q: How is steel wire rod used in the production of wire mesh for erosion control?

- Steel wire rod is an essential component in the production of wire mesh for erosion control. The wire rod is first passed through a series of machines to undergo a process called wire drawing, where it is stretched to a smaller diameter and shaped into a long, continuous wire. This wire is then further processed to achieve the desired thickness and strength required for erosion control applications. In the production of wire mesh for erosion control, the steel wire rod is typically woven or welded together to create a mesh structure. The wire mesh acts as a physical barrier to prevent soil erosion by holding the soil in place, especially on sloping terrain or areas prone to water flow. The wire rod's high tensile strength and durability make it an ideal material for erosion control applications. The wire mesh produced from steel wire rod is capable of withstanding harsh environmental conditions, such as heavy rainfall or strong water currents, without deforming or breaking. The wire mesh can be tailored to specific erosion control needs by adjusting the gauge and spacing of the wires. Thicker wires and smaller spacing are used for applications that require higher strength and stability, such as retaining walls or embankments. On the other hand, thinner wires and wider spacing may be suitable for less demanding erosion control situations, such as stabilizing soil on residential properties or landscaping projects. Overall, the use of steel wire rod in the production of wire mesh for erosion control provides a reliable and long-lasting solution to prevent soil erosion. Its versatility allows for customization based on specific project requirements, ensuring effective erosion control measures are implemented in various applications.

- Q: What are the main factors affecting the mechanical properties of steel wire rod?

- The main factors affecting the mechanical properties of steel wire rod include the chemical composition of the steel, the microstructure and grain size, the heat treatment process, and any mechanical or thermal processing that the wire rod undergoes. These factors can greatly influence the strength, ductility, toughness, and other mechanical properties of the steel wire rod.

- Q: How is steel wire rod used in the manufacturing of wire for suspension systems in trains?

- Steel wire rod is a crucial component in the manufacturing of wire for suspension systems in trains. It is first processed and drawn into the desired diameter to create high-strength wire. This wire is then used to form various suspension components, such as springs and cables, which are essential for maintaining stability, absorbing shocks, and supporting the weight of train cars. The strength, durability, and flexibility of steel wire rod make it an ideal material for ensuring the safety and smooth operation of train suspension systems.

- Q: How is the quality of steel wire rod assessed?

- The quality of steel wire rod is assessed based on various factors, including its chemical composition, physical properties, and surface condition. This assessment is done through rigorous testing and inspection methods such as spectroscopy, tensile strength testing, and visual examination. These evaluations ensure that the steel wire rod meets the required industry standards and specifications, guaranteeing its strength, durability, and suitability for various applications.

- Q: How is steel wire rod used in the manufacturing of wire rope bins?

- Steel wire rod is used in the manufacturing of wire rope bins as it serves as the raw material for producing the wire ropes that make up the structure of the bins. The wire rod is drawn and twisted to form durable and strong wire ropes, which are then woven or braided to create the mesh-like structure of the bins. This ensures that the bins are capable of withstanding heavy loads, providing a secure containment solution for various materials and goods.

- Q: What are the main growth drivers for the steel wire rod market?

- The steel wire rod market is driven by several key factors. Firstly, the construction industry plays a crucial role in driving demand for steel wire rods. These rods are extensively used in various construction applications, such as reinforcing concrete structures, building fences, and constructing suspension bridges. Given the ongoing urbanization and infrastructure development worldwide, the construction sector's demand for steel wire rods is anticipated to experience significant growth. Secondly, the automotive industry serves as another major driver for the steel wire rod market. Steel wire rods are essential in manufacturing automobile parts, including springs, tires, and suspension systems. As the automotive industry continues to expand globally, particularly in emerging markets, the demand for steel wire rods will inevitably increase to meet the rising production needs. Additionally, the energy sector also contributes to the growth of the steel wire rod market. Steel wire rods are vital in producing electrical cables, power transmission lines, and oil and gas pipelines. With the global demand for energy steadily increasing, there will be a higher requirement for steel wire rods to support the infrastructure necessary for energy production and distribution. Furthermore, the growing demand for consumer goods, such as electronics and appliances, plays a significant role in driving the steel wire rod market. These rods are used in manufacturing various consumer goods, including kitchen appliances, furniture, and electronic devices. As consumer spending rises and new markets emerge, the demand for steel wire rods in the consumer goods sector is expected to witness a notable surge. Lastly, technological advancements and innovations in steel manufacturing processes are propelling the growth of the steel wire rod market. These advancements have led to the production of high-quality steel wire rods with enhanced strength and durability, making them highly desirable for various applications. Additionally, the development of advanced machinery and equipment for steel wire rod production has improved efficiency and reduced production costs, further bolstering market growth. In conclusion, the primary drivers for the steel wire rod market encompass the construction industry, automotive industry, energy sector, demand for consumer goods, and technological advancements. As these industries continue to expand and evolve, the demand for steel wire rods is projected to rise, thereby stimulating market growth.

- Q: What are the different types of steel wire rod finishes for improved adhesion in rubber products?

- There are several types of steel wire rod finishes that can enhance adhesion in rubber products. Some common finishes include copper, zinc, phosphate, and brass coatings. These finishes help to create a stronger bond between the steel wire rod and the rubber, improving adhesion and overall product performance.

Send your message to us

Wire rod with hot price 5.5mm-12mm different grade

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 19710 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords