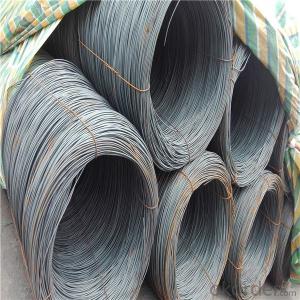

Prime alloy steel wire rod different grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 17623 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wire rod is a rolled alloy or nonalloy steel product, produced from a semi (e.g. bloom) and having a round,

rectangular or other cross-section. Particularly fine cross-sections may be achieved by subsequent cold

forming (drawing). Wire rod is wound into coils and transported in this form.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make

for wire mesh.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

FAQ:

1.Q:Can you accept mixed order?

A: Yes, mixed acceptable .

2. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

3. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

4. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: What are the different types of wire mesh filters made from steel wire rod?

- Steel wire rod is used to create a variety of wire mesh filters, which find wide application in industries for purposes like filtration, sieving, and separation. One kind of wire mesh filter, known as the plain weave filter, is produced by weaving the steel wires in a simple over-and-under pattern. This results in a mesh that is uniform and has square-shaped openings. Plain weave filters are renowned for their durability and strength, making them suitable for tasks that require heavy-duty performance. Another type of wire mesh filter is the twill weave filter, created by interlacing the steel wires in a pattern that gives rise to a diagonal or herringbone-like appearance. Compared to plain weave filters, twill weave filters offer a tighter weave and a finer mesh. They are commonly utilized in applications that demand precision and fine filtration. Besides plain and twill weaves, there are other wire mesh filters made from steel wire rod. These include Dutch weave filters, reverse Dutch weave filters, and welded wire mesh filters. Dutch weave filters have a coarser mesh with more wires in the weft direction, while reverse Dutch weave filters have a finer mesh with more wires in the warp direction. Welded wire mesh filters are produced by welding the intersections of the steel wires, resulting in a mesh structure that is stronger and more rigid. Overall, the various types of wire mesh filters made from steel wire rod offer a range of options to meet diverse filtration requirements. Whether it is for coarse or fine filtration, heavy-duty or precision applications, these filters provide efficient and dependable solutions.

- Q: How does the brittleness of steel wire rod vary with different wire drawing processes?

- Different wire drawing processes can result in varying brittleness of steel wire rod. Wire drawing involves reducing the wire's diameter by pulling it through dies. The specific process used has a significant impact on the wire's final properties, including brittleness. One factor affecting brittleness is the reduction in area during wire drawing. This refers to the amount of material removed as the wire passes through the dies. Higher reductions in area lead to more deformation and strain, increasing brittleness. This occurs because the steel's grain structure becomes elongated and aligned, making it more prone to cracking and breaking under stress. Another influence on brittleness is the drawing speed. Higher speeds create greater strain and deformation, increasing brittleness. Rapid cooling during drawing can also contribute to brittleness by promoting the formation of brittle phases in the steel structure. The heat treatment applied after drawing can also impact brittleness. Processes like annealing can relieve internal stresses and improve wire ductility, reducing brittleness. Conversely, improper heat treatment or inadequate cooling can increase brittleness. To achieve desired mechanical properties, manufacturers must carefully control factors such as reduction in area, drawing speed, cooling rate, and heat treatment. By doing so, they can ensure the desired brittleness of the steel wire rod.

- Q: How does the hardness of steel wire rod vary with different heat treatment processes?

- The hardness of steel wire rod can differ greatly depending on the heat treatment processes employed. Heat treatment is a controlled procedure utilized to modify the characteristics of steel through specific heating and cooling conditions. Annealing, quenching, and tempering are the three primary heat treatment processes employed for steel wire rod. During annealing, the steel wire rod is heated to a specific temperature and then gradually cooled, typically within a furnace. This process serves to relieve internal stresses, enhance ductility, and refine the grain structure of the steel. Consequently, the hardness of the steel wire rod decreases, rendering it softer and more pliable. On the other hand, quenching entails rapidly cooling the steel wire rod by immersing it in a quenching medium, such as oil, water, or a polymer solution. This rapid cooling prevents the formation of a more stable crystal structure, resulting in a harder and more brittle material. The hardness achieved through quenching depends on the rate of cooling and the steel's composition. Steels with higher carbon content generally exhibit higher hardness after quenching. Tempering is a subsequent process to quenching. It involves reheating the quenched steel wire rod to a specific temperature below its critical point and subsequently allowing it to cool gradually. This process diminishes the brittleness caused by quenching and enhances the toughness and ductility of the steel. The hardness achieved through tempering is generally lower than that achieved through quenching, but the steel wire rod becomes more suitable for various applications that require a balance between hardness and toughness. In conclusion, the hardness of steel wire rod varies depending on the heat treatment processes employed. Annealing reduces hardness, resulting in softer and more pliable steel. Quenching increases hardness, yielding a harder and more brittle material. Tempering achieves a balance between hardness and toughness, making the steel wire rod more suitable for specific applications. The selection of a heat treatment process depends on the desired mechanical properties and intended use of the steel wire rod.

- Q: What are the different surface defects that can impact the corrosion resistance of steel wire rod?

- There are several surface defects that can impact the corrosion resistance of steel wire rod. These include scale, pits, scratches, and oxide inclusions. Scale refers to the thin layer of iron oxide that forms on the surface of steel during the manufacturing process. Pits are small cavities or depressions that can form on the surface due to localized corrosion. Scratches can provide a site for corrosion initiation and propagation. Oxide inclusions are foreign particles embedded in the steel, which can act as corrosion initiation sites. All these surface defects can compromise the corrosion resistance of steel wire rod, making it more susceptible to rust and corrosion.

- Q: How is steel wire rod used in the manufacturing of wire forms for display racks?

- The manufacturing of wire forms for display racks heavily relies on steel wire rod. This component plays a vital role as the raw material that is subjected to a range of manufacturing processes in order to create wire forms with precise shapes and sizes. The initial step involves carefully selecting the appropriate quality and diameter of steel wire rod. This selection process is dependent on the desired strength, durability, and flexibility of the wire forms. Once the suitable steel wire rod has been chosen, it is fed into a wire drawing machine. In this machine, the steel wire rod is pulled through a series of dies, effectively reducing its diameter and increasing its length. Once the wire has been successfully drawn to the desired size, it proceeds to undergo a series of shaping and bending processes. These processes may entail the utilization of specialized machines or tools to bend the wire into specific angles, curves, or shapes that are required for the display racks. Additionally, the wire may also be cut into specific lengths as per the design requirements. In order to retain the desired shape and structure of the wire forms, further processes such as heat treatment or galvanization may be carried out. Heat treatment serves to strengthen the wire forms, making them more resistant to bending or deforming when subjected to heavy loads. On the other hand, galvanization entails applying a protective layer of zinc onto the wire forms to safeguard against corrosion, thereby enhancing their lifespan. Once the wire forms have been shaped, bent, and treated, they are now ready to be assembled into the display racks. These wire forms can be employed for various purposes within the display rack industry, such as forming shelves, hooks, or frames. The versatility of steel wire rod allows for the production of wire forms in different designs, sizes, and load capacities, thus enabling them to meet the specific requirements of display rack applications. To summarize, the manufacturing process of wire forms for display racks heavily relies on steel wire rod. This crucial component undergoes a range of processes including wire drawing, shaping, bending, and treatment to produce wire forms with specific shapes, sizes, strength, and durability. Once assembled into display racks, these wire forms provide a robust and adaptable solution for showcasing products.

- Q: What are the specifications for steel wire rod in different international standards?

- The specifications for steel wire rod vary in different international standards, but generally include criteria such as the chemical composition, mechanical properties, dimensions, and tolerances. These standards may differ in terms of specific requirements, such as the maximum carbon or sulfur content, tensile strength, or diameter range. Some commonly referenced international standards for steel wire rod include ASTM A510 (United States), EN 10016 (Europe), JIS G 3505 (Japan), and GB/T 4354 (China). It is important to consult the relevant standard for specific details regarding the specifications of steel wire rod.

- Q: How long does it take to produce steel wire rod from raw materials?

- The production process of steel wire rod from raw materials can vary depending on several factors, including the specific manufacturing method, equipment used, and the desired quality and specifications of the final product. Generally, the process involves several stages, including iron ore extraction, ironmaking, steelmaking, casting, and rolling. Iron ore extraction involves mining and processing iron-rich rocks or minerals, which can take varying amounts of time depending on the location and size of the mine. Once the iron ore is extracted, it goes through a series of processes, including crushing, grinding, and beneficiation, to remove impurities and improve its quality for steel production. Ironmaking is the next stage, where the processed iron ore is transformed into molten iron through a blast furnace or direct reduction process. This stage typically takes several hours to complete, depending on the size and efficiency of the furnace. Steelmaking, also known as primary steel production, involves converting molten iron into steel by removing excess carbon and other impurities. This process is typically carried out in a basic oxygen furnace or electric arc furnace and can take several hours to complete. Once the steel is produced, it needs to be cast into semi-finished products like billets or blooms, which can take several minutes to hours depending on the casting method and equipment used. Finally, the steel is shaped into wire rod through the rolling process, where it is passed through a series of rolling mills to reduce its diameter and achieve the desired dimensions. Rolling can take anywhere from a few minutes to several hours, depending on the required length and thickness of the wire rod. Overall, the time required to produce steel wire rod from raw materials can vary significantly depending on the specific processes, equipment, and quality standards involved, but it generally ranges from several hours to several days.

- Q: What are the common applications of high carbon and oil tempered steel wire rod?

- High carbon and oil tempered steel wire rod have a wide range of applications due to their unique properties. Some of the common applications of these materials include: 1. Springs: High carbon and oil tempered steel wire rod are commonly used in the manufacturing of springs due to their excellent strength, flexibility, and durability. These materials can withstand high stress and repeated bending, making them ideal for various types of springs, including automotive suspension springs, valve springs, and mattress springs. 2. Wire ropes and cables: High carbon and oil tempered steel wire rod are also used in the production of wire ropes and cables. These materials offer high tensile strength and resistance to wear, making them suitable for applications that require heavy lifting, such as cranes, elevators, and suspension bridges. 3. Wire mesh and fencing: The strength and durability of high carbon and oil tempered steel wire rod make them ideal for manufacturing wire mesh and fencing products. These materials provide excellent security and can withstand harsh weather conditions, making them suitable for use in construction sites, agriculture, and animal enclosures. 4. Automotive applications: High carbon and oil tempered steel wire rod are widely used in the automotive industry. They are used in the production of various components, including engine valve springs, clutch springs, and brake springs. These materials offer high fatigue resistance and can withstand the demanding conditions of automotive applications. 5. Construction and infrastructure: High carbon and oil tempered steel wire rod are used in the construction industry for various applications. They are used in the reinforcement of concrete structures, such as beams, columns, and precast elements. The high strength and corrosion resistance of these materials make them suitable for withstanding the stresses and environmental conditions encountered in construction projects. 6. Industrial machinery: High carbon and oil tempered steel wire rod find applications in the production of industrial machinery and equipment. They are used in the manufacturing of conveyor belts, machine components, and wire forms. These materials provide the necessary strength and flexibility required for smooth and efficient operation of industrial machinery. In conclusion, high carbon and oil tempered steel wire rod have numerous applications across various industries. Their high strength, durability, and flexibility make them ideal for springs, wire ropes, wire mesh, automotive components, construction reinforcement, and industrial machinery.

- Q: What are the common industry qualifications for steel wire rod professionals?

- Common industry qualifications for steel wire rod professionals can vary depending on the specific role and level of expertise required. However, some of the common qualifications include a degree or certification in materials science, metallurgy, or mechanical engineering. Additionally, specialized certifications such as Certified Welding Inspector (CWI) or Certified Materials Professional (CMP) can also be beneficial in demonstrating expertise in the field. Experience working with steel wire rod production processes and knowledge of industry standards and regulations are also highly valued qualifications.

- Q: How is steel wire rod coated for corrosion protection?

- Steel wire rod is coated for corrosion protection through a process called galvanization. This involves immersing the wire rod in a bath of molten zinc, which forms a protective layer over the surface of the steel. The zinc coating acts as a barrier, preventing contact between the steel and corrosive elements, thereby significantly reducing the risk of corrosion.

Send your message to us

Prime alloy steel wire rod different grade

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 17623 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords