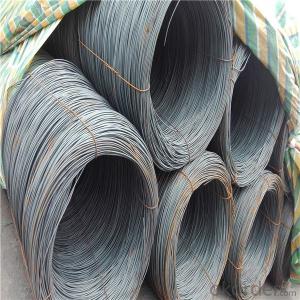

Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality is widely used in construction and manufacturing. Carbon steel wire rod is mainly used for reinforcement of reinforced concrete and welded structure or reprocessed (roberts , nail, etc.) materials, especially used to produce wire drawing, welding electrode, nails, spring, electronic, precise machinery parts and so on.

Product Advantages:

OKorder's Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality are durable, strong.packed and suitable for wire mesh,nail manufacture and construction

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Manufacture: Hot rolled

Grade: SAE1006 SAE1008 SAE1010 SAE1012 SAE1016 SAE1018

Certificates: ISO, SGS, BV, CIQ

Weight per Coil:2-2.05tons

Packaging: Export packing, packed by coil

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q4: How many tons can be loaded into one 20ft container?

A4: Around 18—20tons

Q5: What is the chemical composition and physical properties of SAE1008?

A5:

Grade | Chemical Composition (%) | |||||

C | Mn | S | P | Si | B | |

SAE1008B | 0.10max | 0.32max | 0.045max | 0.040max | 0.30max | 0.0008min |

Mechanical properties | ||||||

Yield strength(N/mm2) | Tensile strength(N/mm2) | Elongation (%) | ||||

≥195 | 350-380 | ≥32 | ||||

Images

- Q: How is steel wire rod used in the manufacturing of wire for power distribution systems?

- Steel wire rod is a crucial component in the manufacturing of wire for power distribution systems. It serves as the raw material from which the actual wire is produced. Firstly, steel wire rod is commonly made from carbon steel and has high tensile strength, making it ideal for carrying electricity over long distances. The wire rod undergoes a series of processes such as hot rolling, drawing, and annealing to turn it into a thin and flexible wire. During the hot rolling process, the steel wire rod is heated to a specific temperature and then passed through a series of rollers to reduce its diameter. This process helps in refining the steel's grain structure, enhancing its strength and flexibility. Next, the wire rod is drawn through a series of dies to further reduce its diameter and increase its length. This drawing process also improves the wire's mechanical properties, such as its tensile strength and conductivity. The wire rod is pulled through the dies by a drawing machine, resulting in a continuous length of wire. After the wire is drawn, it undergoes an annealing process, which involves heating it to a specific temperature and then slowly cooling it. Annealing helps relieve any residual stresses in the wire, making it more flexible and easier to handle during the manufacturing process. Once the wire rod has been transformed into wire, it can be further processed and insulated to meet the specific requirements of power distribution systems. Insulation materials such as PVC or XLPE (cross-linked polyethylene) are applied to the wire to provide electrical insulation and protect against moisture, temperature fluctuations, and physical damage. Finally, the insulated wire is used to manufacture various components of power distribution systems, including cables, conductors, and overhead lines. These wires are utilized to transmit electricity from power plants to substations, then further distributed to homes, businesses, and other facilities. In summary, steel wire rod is an essential material in the manufacturing of wire for power distribution systems. Through processes such as hot rolling, drawing, and annealing, the wire rod is transformed into thin and flexible wire, which is then insulated to meet the specific requirements of power distribution applications. This wire plays a crucial role in carrying electricity safely and efficiently over long distances.

- Q: How are steel wire rods used in the production of electrical wires for conducting electricity?

- Steel wire rods are used in the production of electrical wires as the core material for conducting electricity. The rods are drawn through a series of dies to reduce their diameter and increase their length. This process, known as wire drawing, creates a smooth and uniform wire that is then coated with an insulating material, such as PVC or rubber, to ensure electrical safety. The resulting electrical wire is flexible, durable, and capable of efficiently transmitting electricity without any significant loss.

- Q: What are the major growth strategies adopted by companies in the steel wire rod industry?

- Companies in the steel wire rod industry utilize various strategies to expand their market share and increase profitability. Some of the key strategies employed by these companies include: 1. Expanding Market Reach: Companies aim to extend their market presence by targeting new geographical regions or entering different market segments. This involves investing in market research and developing new distribution channels to reach a broader customer base. 2. Investing in Product Innovation: Steel wire rod companies constantly invest in research and development to create new and improved products. They strive to stay ahead of the competition by offering innovative solutions that cater to the evolving needs and preferences of customers. This strategy helps companies attract new customers and retain existing ones. 3. Vertical Integration: Some companies in the steel wire rod industry adopt a vertical integration strategy by acquiring or investing in companies involved in the upstream or downstream processes of the industry. By integrating backward or forward in the value chain, companies gain more control over their supply chain, reduce costs, and enhance competitiveness. 4. Collaborating through Strategic Partnerships and Alliances: Collaborating with other industry players through strategic partnerships and alliances can be an effective growth strategy. Companies can benefit from shared resources, exchange of knowledge, and joint marketing efforts, leading to increased market penetration and customer acquisition. 5. Pursuing Mergers and Acquisitions: Mergers and acquisitions are common in the steel wire rod industry as companies aim to consolidate their market position and achieve economies of scale. By acquiring or merging with other companies, they can eliminate competition, access new markets, and diversify their product offerings. 6. Diversifying into Related Industries or Product Lines: Steel wire rod companies may also adopt a diversification strategy by expanding into related industries or product lines. This strategy allows companies to reduce their reliance on a single market and mitigate risks associated with market fluctuations. For example, a company may diversify into manufacturing wire mesh or wire products for different industries. 7. Improving Operational Efficiency: Enhancing operational efficiency is a crucial growth strategy for companies in the steel wire rod industry. By investing in advanced technologies, automation, and lean manufacturing practices, companies can reduce costs, increase productivity, and improve overall profitability. It should be noted that the specific growth strategies employed by companies in the steel wire rod industry may vary depending on their size, resources, and market dynamics. However, these strategies provide a general overview of the major approaches used by companies to achieve growth and success in this highly competitive industry.

- Q: How is steel wire rod used in the manufacturing of suspension components for automobiles?

- Due to its superior strength and durability, steel wire rod is widely utilized in the production of suspension components for automobiles. These essential components, including coil springs, torsion bars, and stabilizer bars, are responsible for providing stability, control, and comfort to the vehicle's ride. Coil springs, a crucial part of the suspension system, are manufactured using steel wire rods. Designed to absorb shocks and vibrations from the road, coil springs ensure a smooth and comfortable ride for passengers. The steel wire rod is typically shaped into a helical form and possesses high tensile strength, enabling it to withstand the compression and extension forces exerted on it. Another type of suspension component utilizing steel wire rod is the torsion bar. These bars resist the twisting motion of the suspension system, promoting stability and preventing excessive body roll during cornering. Torsion bars made from steel wire rods with specific properties, such as high yield strength and torsional rigidity, are able to withstand the required torque and stress. Stabilizer bars, also known as sway bars or anti-roll bars, are commonly employed in suspension systems to reduce body roll during cornering. These bars are constructed using steel wire rods with specific diameters and stiffness. By forming the steel wire rod into a tubular shape, the stabilizer bar can effectively resist the twisting forces encountered when the vehicle turns. The high strength of the steel wire rod ensures that the stabilizer bar can efficiently transfer forces from one side of the suspension system to the other, minimizing body roll and enhancing vehicle stability. To recapitulate, steel wire rod plays a vital role in the manufacturing of suspension components for automobiles. Its exceptional strength, durability, and resistance to various forces make it an ideal material for coil springs, torsion bars, and stabilizer bars. By incorporating steel wire rods in the production of suspension components, automotive manufacturers can guarantee the performance, safety, and comfort of their vehicles.

- Q: What are the main factors influencing the choice of steel wire rod buyer?

- The choice of steel wire rod buyer can be influenced by various factors, depending on the specific needs and requirements of the buyer. However, there are several common factors that significantly impact the decision-making process. Firstly, buyers place utmost importance on the quality of steel wire rods. They carefully assess factors such as composition, strength, and durability. Furthermore, buyers evaluate the supplier's quality control measures, certifications, and track record to ensure that they receive high-quality products that meet their specifications. Secondly, pricing plays a crucial role for buyers as it directly affects their overall costs. Buyers compare prices from different suppliers to find the most competitive offer without compromising on quality. Negotiations may occur to reach a mutually beneficial agreement. Thirdly, buyers prefer suppliers who demonstrate reliability by consistently meeting their demands and delivering products on time. Reliability in terms of product availability, timely delivery, and consistent performance is crucial for buyers to ensure smooth operations and avoid disruptions in their supply chain. Furthermore, steel wire rod buyers often require technical support from their suppliers. They seek assistance in selecting the appropriate grade and size of wire rods for their specific applications. Additionally, buyers value suppliers who provide technical data and specifications and offer expertise in troubleshooting or addressing any concerns that may arise during usage. In addition, the reputation and trustworthiness of potential suppliers are important considerations for buyers. They may request references, reviews, and feedback from other customers to evaluate the supplier's track record and reliability. A good reputation can instill confidence in buyers and influence their decision. Moreover, buyers appreciate suppliers who offer excellent after-sales service. This includes providing assistance with any issues or concerns that arise after the purchase, offering warranty or guarantee programs, and providing ongoing support to ensure customer satisfaction. Lastly, with the increasing emphasis on sustainability, buyers are becoming more mindful of the environmental impact of their purchases. They may prefer suppliers who employ sustainable and environmentally friendly practices, such as using recycled materials or implementing energy-efficient production processes. In conclusion, the choice of steel wire rod buyer is influenced by factors such as quality, price, reliability, technical support, reputation, after-sales service, and sustainability considerations. By considering these factors, buyers can make informed decisions that not only meet their immediate needs but also align with their long-term goals and values.

- Q: What are the different types of steel wire rod finishes for improved adhesion?

- There are several types of steel wire rod finishes that can improve adhesion, including phosphatized, galvanized, and polymer coated finishes.

- Q: How are steel wire rods used in the production of wire mesh?

- Steel wire rods are used as a primary raw material in the production of wire mesh. The rods are first drawn through a series of dies to reduce their diameter and increase their length. These drawn wires are then fed into a mesh weaving machine, where they are interlaced to form a grid pattern. The resulting wire mesh is commonly used for various applications such as reinforcement in concrete, fencing, and filtration systems.

- Q: How is steel wire rod used in the manufacturing of wire for suspension systems in buildings?

- Steel wire rod is a crucial component in the manufacturing of wire for suspension systems in buildings. It serves as the raw material from which the wire is produced. The steel wire rod undergoes a series of processes such as cleaning, drawing, and annealing to transform it into high-quality wire with specific properties like strength and flexibility. This wire is then utilized in the construction of suspension systems, providing support and stability to various building structures such as ceilings, bridges, and curtain walls.

- Q: What are the different types of steel wire rod packaging options after wire drawing?

- After wire drawing, there are several packaging options available for steel wire rods. These options are designed to protect the wire rods during storage, transportation, and handling. The different types of steel wire rod packaging options include: 1. Coils: Steel wire rods can be packaged in the form of coils. The wire is wound around a cylindrical core, creating a compact and secure package. Coils are widely used for packaging steel wire rods, as they are easy to handle, stack, and transport. They are commonly available in different sizes, ranging from small coils for lightweight wire rods to larger coils for heavier gauge wire rods. 2. Spools: Spools are another popular packaging option for steel wire rods. The wire is wound around a spool, which provides a more organized and controlled arrangement. Spools are commonly used for smaller diameter wire rods, especially in industries where precision and ease of use are important, such as electrical and electronics industries. 3. Straight bars: In some cases, steel wire rods are packaged as straight bars. This packaging option is suitable for wire rods with larger diameters and lengths. Straight bars are often used in industries where the wire rods are further processed or cut into specific lengths for various applications. 4. Bundles: Steel wire rods can also be packaged in bundles. Bundles are created by tying together multiple wire rods using straps or wires. This packaging option is commonly used for longer wire rods that cannot be coiled or spooled. Bundles provide stability and protection to the wire rods during transportation and storage. 5. Pallets: Pallets are used to package wire rods in bulk quantities. The wire rods are stacked and secured on wooden or plastic pallets, ensuring easy handling and efficient storage. Pallets are commonly used for larger wire rod shipments, allowing forklifts or pallet jacks to move and transport the wire rods easily. 6. Containers: For international shipments or long-distance transportation, steel wire rods can be packaged in containers. Containers provide a secure and protected environment for wire rods, preventing damage from moisture, dust, or other external factors during transit. It is important to select the appropriate packaging option based on the size, weight, and specific requirements of the steel wire rods. Proper packaging ensures the integrity and quality of the wire rods, minimizing the risk of damage and facilitating efficient handling and transportation.

- Q: How is steel wire rod used in the production of wire mesh screens?

- Wire mesh screens, widely utilized in construction, mining, agriculture, and manufacturing, owe their durability and versatility to the crucial component of steel wire rod. To manufacture wire mesh screens, the starting material is the steel wire rod. This rod, typically made from low carbon steel, undergoes a series of processes to reach its final form. An initial step involves drawing the steel wire rod through dies, effectively reducing its diameter and increasing its length. This process, known as wire drawing, yields long continuous strands of thin steel wire. Subsequently, these wire strands go through further processing using various machines to attain the desired shape and dimensions. By weaving or welding the wire together, a grid-like pattern is formed, creating the wire mesh screen. In order to meet specific application requirements, wire mesh screens can be customized with different opening sizes, wire diameters, and weaving patterns. For example, screens used in construction may feature larger openings to facilitate better airflow, while those used in mining may have smaller openings to effectively filter out specific-sized particles. The use of steel wire rod in the production of wire mesh screens guarantees strength and durability. Steel is renowned for its high tensile strength, enabling the screens to endure heavy loads, impacts, and adverse environmental conditions. Moreover, steel wire rod provides excellent corrosion resistance, a critical factor for wire mesh screens used outdoors or in industries exposed to moisture, chemicals, or other corrosive substances. In summary, the importance of steel wire rod in the production of wire mesh screens cannot be overstated. Its contribution lies in providing the necessary strength, durability, and corrosion resistance. These screens, known for their versatility and ability to meet specific application requirements, find extensive use across various industries.

Send your message to us

Hot Rolled Carbon Steel Wire Rod 5.5mm with High Quality

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords