Steel wire rod large stock 5.5mm-14mm different grad

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 14231 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Wire rod is used for many different products. Depending upon how it is cold formed and heat treated,

wire is used, for example, to produce not only wire ropes, barbed wire, wire mesh and nails, but also

springs, welded wire mesh and reinforcement wire.

Our service:

(1) We cooperate with famous factories with advanced equipment and well trained workers.

(2) We can provide factory price with trading company service.

(3) We continuously work on the improvement of our processes, guaranteeing

consistently high standards of quality to keep none compensation.

(4) We guarantee 24 hours response and 48 hours solution providing service.

(5) We accept small order quantity before formal cooperation.

(6) We deliver the agreed quality at the agreed time, reacting to changes in

customer wishes in a flexible way.

(7) Due to our volume and selling power, we have excellent freight rates with

shipping lines.

(8) We strive to always be fair and honest in our dealings with customers.

(9) We strive to work together with customers to achieve much more than we can

achieve alone.

(10) Through our passion and commitment we aim to be a market leader in all our

key markets. To maintain our position as market leader we must continue to add

value in all that we do.

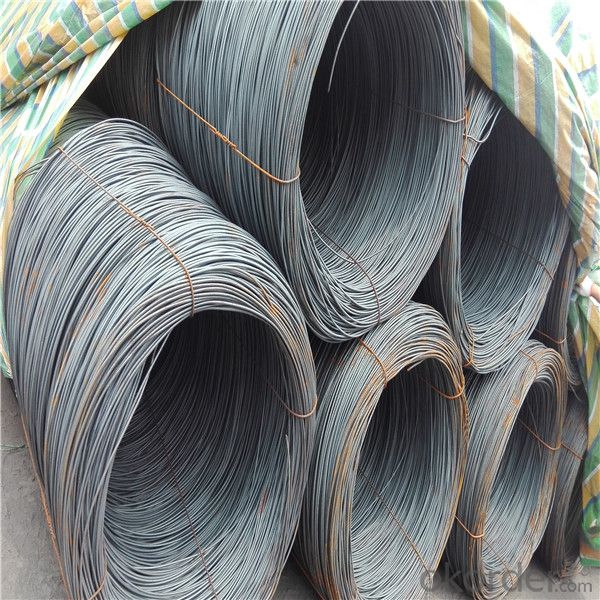

Product Description :

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material/steel grade | Q195-Q235,SAE1006B,SAE1006CR, SAE1008B, SAE1008CR, SAE1010B, SAE1018B, or according to customers requirements |

Wire Gauge | 5.5-12mm |

Coil weight | 1.8-2.1mts |

MOQ | 25MT |

Delivery Time | 15-30 days after receipt of L/C or deposit by T/T |

Packing | In coil and load in container, if large quantity, by bulk vessel; Can be packed as customers' special requirements |

Payment terms | 1).100% irrevocable L/C at sight. 2).30% T/T prepaid and the balance against the copy of B/L. 3).30% T/T prepaid and the balance against L/C |

Application | widely used in machinery parts, manufacturing industry, electronics industry, metal tools and others |

Application :

Mainly used in building and construction as binding wire, tie wire and baling wire; also can be make

for wire mesh.

Packing :

Hot-rolled wire rod is held in a unit with at least four steel straps in the

transverse direction and transported and stored without further packaging.

Before

the steel strapping is applied, the wire rod must be sufficiently compressed.

The strapping is fixed in the transverse direction with a single circumferential

strap so that the strapping does not slip and cause the coil to come apart.

FAQ:

1.Q:Can you accept mixed order?

A: Yes, mixed acceptable .

2. Q: How can I buy CNBM products in my country?

A:Please send us an inquiry or email ,we will reply to you if there is distributor in your country

3. Q: Can we visit your factory?

A: Warmly welcome. Once we have your schedule, we will arrange the

professional sales team to follow up your case.

4. Q: How long does it take to get the product if i place an order?

A:With the process of your requirements,we will pack and deliver in 3

-7 days. If it is by sea shipment,it will take 15-45 days depending on different locations

- Q: How is steel wire rod used in the manufacturing of wire forms for conveyor belts?

- Steel wire rod is used in the manufacturing of wire forms for conveyor belts as it serves as the raw material for creating the wires that make up the belts. The steel wire rod is first drawn and shaped into the desired wire diameter and then woven or welded together to form the wire mesh or spiral strands that make up the conveyor belt. This ensures the strength, durability, and flexibility necessary for the conveyor belt to effectively transport materials.

- Q: How is steel wire rod used in the manufacturing of wire forms for musical instruments?

- Steel wire rod is an essential component in the manufacturing of wire forms for musical instruments. It serves as the base material for creating various wire shapes, such as springs, hooks, and braces, which are crucial for holding instrument parts together or providing tension. The high-quality and strength of steel wire rod ensure durability and reliability in these wire forms, enabling musicians to produce precise and harmonious sounds from their instruments.

- Q: How is steel wire rod used in the manufacturing of wire mesh for concrete reinforcement?

- Steel wire rod is used in the manufacturing of wire mesh for concrete reinforcement by being formed into a grid-like pattern. This wire mesh is then embedded within the concrete to provide added strength and stability, preventing cracking and ensuring durability. The steel wire rod acts as a reinforcement, distributing the load and increasing the overall structural integrity of the concrete.

- Q: How is the brittleness of steel wire rod determined?

- The brittleness of steel wire rod is typically determined by conducting a series of mechanical tests, such as the Charpy impact test or the tensile test. These tests help measure the amount of force or energy required to fracture or break the steel wire rod, providing an indication of its brittleness. Additionally, microscopic examination techniques, like optical microscopy or scanning electron microscopy, can be used to analyze the internal structure of the steel wire rod and identify any signs of brittleness, such as the presence of cracks or grain boundaries.

- Q: What are the different coating options available for steel wire rod?

- There are several different coating options available for steel wire rod, each providing unique benefits and characteristics. Some of the most common coating options include: 1. Galvanized Coating: This is one of the most popular coating options for steel wire rod. It involves applying a layer of zinc to the surface of the wire rod, which provides excellent corrosion resistance. Galvanized coating also enhances the durability and lifespan of the wire rod. 2. Epoxy Coating: Epoxy coating is a type of protective coating that is applied to steel wire rod to provide resistance against corrosion and abrasion. It creates a smooth and durable surface that prevents moisture and other corrosive elements from reaching the wire rod. 3. Polymer Coating: Polymer coatings are commonly used for steel wire rod that is exposed to harsh environmental conditions. These coatings provide excellent resistance against corrosion, chemicals, and UV radiation. Polymer coatings also enhance the aesthetic appearance of the wire rod. 4. Phosphating Coating: Phosphating is a chemical treatment that is applied to steel wire rod to enhance its corrosion resistance. This coating option converts the surface of the wire rod into a layer of phosphate crystals, which creates a protective barrier against rust and other forms of corrosion. 5. Powder Coating: Powder coating is a popular choice for steel wire rod that requires a decorative finish. This coating option involves applying a dry powder to the wire rod and then baking it to create a hard and durable coating. Powder coatings offer excellent resistance against corrosion, chemicals, and scratches. 6. Ceramic Coating: Ceramic coatings are often used for steel wire rod that is exposed to extreme temperatures or abrasive environments. These coatings provide excellent resistance against heat, wear, and corrosion. Ceramic coatings also enhance the strength and durability of the wire rod. It is important to choose the appropriate coating option based on the specific requirements and the intended application of the steel wire rod. Consulting with a coating specialist or manufacturer can help determine the most suitable coating option for the desired purpose.

- Q: How is steel wire rod used in the manufacturing of fasteners?

- Steel wire rod is commonly used in the manufacturing of fasteners as it provides the necessary strength and durability required for various applications. It is typically processed further, undergoing drawing and cold-heading processes to form the desired shape and size of the fastener. The steel wire rod serves as the primary raw material, ensuring that the fasteners possess the required tensile strength and corrosion resistance, making them reliable and long-lasting.

- Q: How is steel wire rod used in the manufacturing of suspension cables?

- Suspension cables, which are crucial components in structures like bridges and buildings, rely on steel wire rod for their strength and durability. This material is chosen because of its unique properties, such as high tensile strength, which enables it to bear heavy loads without breaking. To enhance its mechanical properties, the steel wire rod undergoes a process called wire drawing, where its diameter is reduced and length increased. Additionally, a protective coating is applied to prevent corrosion. The processed wire is then twisted together to form strands, which are further twisted to create a cable. The specific requirements of the suspension cable determine the number of strands and arrangement of wires. Once installed and tensioned, the high strength of the steel wire rod ensures that the cable can effectively support the weight of the structure. Its durability also guarantees the reliability and safety of the suspension cable over time. In conclusion, steel wire rod is essential in the manufacturing of suspension cables due to its strength, durability, and resistance to corrosion. It is the primary material used to create these cables, ensuring their ability to support heavy loads and maintain stability in various structures.

- Q: What are the different microscopy techniques used for steel wire rod analysis?

- There are several microscopy techniques that can be used for steel wire rod analysis. These techniques provide valuable information about the microstructure, composition, and defects in the wire rod. 1. Optical Microscopy: This is a commonly used technique that involves using visible light to observe the microstructure of the wire rod. It can provide information about the grain size, grain boundaries, and any visible defects such as cracks or inclusions. 2. Scanning Electron Microscopy (SEM): SEM uses a focused beam of electrons to obtain high-resolution images of the wire rod's surface. It can provide information about the surface morphology, elemental composition, and the presence of any surface defects or contaminants. 3. Transmission Electron Microscopy (TEM): TEM is a powerful technique that involves passing a beam of electrons through a thin section of the wire rod to obtain detailed images of the internal microstructure. It can provide information about the crystal structure, grain boundaries, and the presence of any precipitates or defects at the atomic level. 4. Electron Backscatter Diffraction (EBSD): EBSD is a technique that combines SEM with crystallography to determine the orientation and grain structure of the wire rod. It can provide information about the crystallographic texture, grain size distribution, and any deformation or recrystallization that may have occurred during processing. 5. X-ray Diffraction (XRD): XRD is a technique that involves directing X-rays onto the wire rod's surface to analyze its crystal structure. It can provide information about the phase composition, crystallographic orientation, and the presence of any residual stress or strain in the wire rod. 6. Atomic Force Microscopy (AFM): AFM uses a small probe to scan the surface of the wire rod and obtain high-resolution images. It can provide information about the surface topography, roughness, and the presence of any surface defects such as scratches or pits. By utilizing these various microscopy techniques, researchers and engineers can gain a comprehensive understanding of the microstructure, composition, and defects in steel wire rods, which is crucial for quality control, process optimization, and material development in the steel industry.

- Q: What are the different types of finishes available for steel wire rod?

- There are several different types of finishes available for steel wire rod, each serving a specific purpose and providing unique properties. 1. Bright Finish: This is the most basic and common finish for steel wire rod. It is achieved by removing any scale or rust from the surface of the rod, resulting in a shiny and smooth appearance. Bright finish is often used for applications where aesthetics are important, such as decorative purposes or in products that are visible to consumers. 2. Galvanized Finish: Galvanizing is a process of applying a protective zinc coating to the surface of the steel wire rod. This finish provides excellent corrosion resistance and is commonly used in outdoor applications or environments with high moisture or humidity. It also offers some degree of abrasion resistance, making it suitable for certain industrial applications. 3. Phosphate Finish: Phosphating is a chemical process that creates a thin layer of phosphate coating on the surface of the steel wire rod. This finish enhances the adhesion of lubricants or coatings, improving the wire's performance in applications where lubrication or corrosion resistance is critical. Phosphate finishes are commonly used in automotive and manufacturing industries. 4. Coated Finish: Steel wire rod can be coated with various materials to provide specific properties. For example, epoxy coatings offer excellent corrosion resistance and are often used in marine or chemical environments. Polymer coatings can provide abrasion resistance, electrical insulation, or improved adhesion properties. Coated finishes are typically tailored to meet specific application requirements. 5. Black Oxide Finish: Also known as blackening, this finish is achieved by converting the surface layer of steel wire rod into a black iron oxide compound. Black oxide finishes provide mild corrosion resistance and improve the wire's appearance. They are commonly used in applications where a black or darkened finish is desired, such as in architectural or decorative products. 6. Zinc-Nickel Finish: This finish is a combination of zinc and nickel plating, providing enhanced corrosion resistance compared to traditional galvanized finishes. Zinc-nickel coatings are commonly used in automotive and aerospace industries, where high corrosion resistance is required. These are just a few examples of the different types of finishes available for steel wire rod. The choice of finish depends on the intended application and the specific properties required, such as corrosion resistance, abrasion resistance, or aesthetics.

- Q: What are the different types of steel wire rod surface defect measurement devices?

- There are various types of devices used for measuring surface defects in steel wire rods. These include optical inspection systems, laser scanning devices, eddy current testing equipment, and ultrasonic testing machines. Each of these devices employs different techniques to detect and analyze defects such as scratches, cracks, pits, and surface roughness in steel wire rods, ensuring product quality and safety in various industries.

Send your message to us

Steel wire rod large stock 5.5mm-14mm different grad

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 14231 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords