Steel Wire Rods Hot Rolled High Carbon First Class Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Wire Rod Steel for Construction Description

Wire rod steel is widely used for commercial building structure, pre-engineering buildings, machinery support structures, prefabricated structure, medium scale bridges and so on. We have supplied this product for many years and gained widespread reputation.

2.Main Features of the Wire Rod Steel for Construction

fasteners, bolts, rivets, screws,

general purpose wires,

electrode wires, industrial wires, agriculture wires,

bush wires, chain rivet wires,

detonator wire,

Umbrella ribs, upholstery wires, cycle spokes, needle wires, heald wires, staple pin Wire, safety pin wires

ACSR wires, earth wires,

tyre and hose reinforcement wires,

prestressed concrete wire, springs and rope wires,

card clothing wires,

vineyard wires,

ball bearing quality

Automobile parts like screw, fasteners, bush, spline, socket, connecting rod, shaft, gear, rivets, engine shaft, connecting rod, spindles, gears, etc.

3.Wire Rod Steel for Construction Images

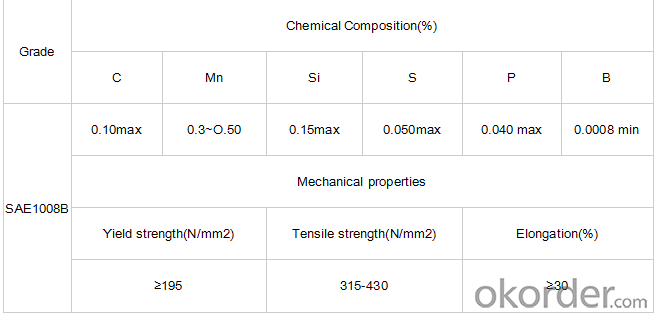

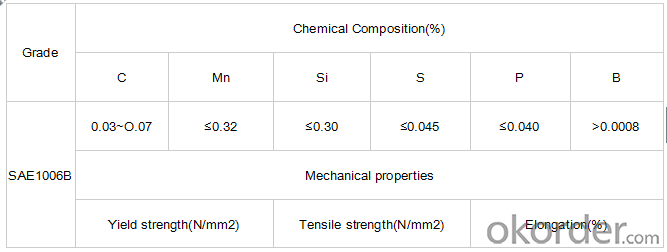

4.Wire Rod Steel for Construction Specification

5.FAQ of Wire Rod Steel for Construction

We have organized several common questions for our clients,may help you sincerely:

1.What is your minimum order quantity ?

Our MOQ is 500mt for each size. And we will consider to give more discount if you make big order like 10000 tons and more. Further more, the more appropriate payment term your offer the better price we can provide.

2.Please tell me the daily output and wire rod mill’s brand ?

Our daily output is 4000mt/day and our rolling mill from Germany’s SMS MEER

3.Which countries are your main sales?

Thanks to the professional international trade team, solid distribution channel and long – term cooperation customers, our market share in overseas realizes a tremendous growth, now we already became a main player in Middle East and South East Asia. Meanwhile, we are also the biggest supplier of Pre-painted galvanized steel coil in Philippines, Saudi Arabia, United Arab Emirates, Iran, Sudan etc.

- Q: What are the main factors influencing the choice of steel wire rod coating?

- The choice of coating for steel wire rods is impacted by several key factors: the intended use, environmental conditions, durability needs, and cost considerations. First and foremost, the intended application of the wire rod is crucial in determining the appropriate coating. Different coatings offer specific properties like corrosion resistance, lubricity, or electrical conductivity. For instance, if the wire rod will be used outdoors or exposed to moisture, a corrosion-resistant coating like zinc or zinc-aluminum is preferred. On the other hand, if the wire rod is intended for electrical purposes, a coating with high electrical conductivity may be necessary. Secondly, the environmental conditions in which the wire rod will be utilized also play a significant role in coating selection. Factors such as temperature, humidity, exposure to chemicals, and UV radiation can impact the coating's performance and durability. Therefore, coatings that exhibit excellent resistance to these environmental factors are often chosen. Durability requirements are another influential factor. Depending on the wire rod's intended lifespan and the level of wear and tear it will face, different coatings with varying levels of durability may be chosen. Some coatings, such as epoxy or polyurethane, offer exceptional resistance to abrasion and impact, making them suitable for applications involving frequent handling or harsh environments. Lastly, cost considerations are important in coating selection. Different coatings come at different price points, and the cost must be balanced with desired performance and durability. It is crucial to choose a coating that meets requirements at a reasonable cost, ensuring a cost-effective solution without compromising the wire rod's performance. In conclusion, the choice of coating for steel wire rods hinges on the intended application, environmental conditions, durability needs, and cost considerations. By taking these factors into account, manufacturers can select the most suitable coating that provides the necessary properties and durability for the specific application while remaining cost-effective.

- Q: What are the different hardness measurement methods for steel wire rod?

- There are several hardness measurement methods for steel wire rods, including Rockwell hardness, Brinell hardness, Vickers hardness, and Knoop hardness. These methods involve applying a specific load to the surface of the wire rod and measuring the depth of indentation or the size of the impression left by the indenter. Each method has its own advantages and limitations, and the choice of method depends on factors such as the type of steel, the desired accuracy, and the specific application of the wire rod.

- Q: What are the main factors influencing the choice of steel wire rod order tracking system?

- Several key factors influence the selection of a steel wire rod order tracking system. To begin with, the size and complexity of the system are important considerations. If the company deals with a large number of orders, it may require a more advanced and sophisticated tracking system to efficiently manage and track them. Conversely, if the company has fewer orders, a simpler system may suffice. Additionally, the specific requirements and needs of the company play a crucial role in determining the choice of order tracking system. Each company may have different priorities and objectives, such as reducing lead times, improving accuracy, or enhancing customer satisfaction. The chosen system should align with these goals and effectively address the company's unique needs. Integration and compatibility with existing systems and processes are also significant factors. The order tracking system should seamlessly integrate with other systems and processes within the company, such as inventory management, production planning, and customer relationship management. This ensures smooth operations and avoids any disruption or duplication of efforts. Furthermore, the order tracking system should be scalable and flexible. As the company grows and expands, the system should be able to accommodate increasing order volumes and changing requirements. It should be easily adaptable to meet the evolving needs of the business. Cost and return on investment are important considerations as well. The system should provide value for money by improving efficiency, reducing errors, and enhancing customer satisfaction. The upfront and ongoing costs of implementing and maintaining the system should be assessed and weighed against the potential benefits. Lastly, the availability of technical support and training is crucial. The chosen tracking system should be supported by a reliable and responsive technical support team, capable of promptly addressing any issues or concerns. Additionally, comprehensive training and documentation should be provided to ensure that the company's employees can effectively utilize and maximize the benefits of the system. In conclusion, the choice of a steel wire rod order tracking system is influenced by various factors, including the size and complexity of the system, specific requirements and needs of the company, integration and compatibility with existing systems, scalability and flexibility, cost and return on investment, and availability of technical support and training. By considering these factors, a company can make an informed decision and select the most suitable order tracking system for their operations.

- Q: How is steel wire rod stored and handled to prevent corrosion?

- To minimize the risk of corrosion, steel wire rod is typically stored and handled in a manner that takes certain precautions. Firstly, it is stored in a dry and well-ventilated location to prevent the accumulation of moisture, which can hasten corrosion. Additionally, the storage area is shielded from direct exposure to rain or other sources of water. To further prevent contact with moisture, steel wire rods are often stored off the ground using racks or pallets. This not only keeps them away from any moisture that may be present on the floor but also allows for better airflow around the stored material, reducing the likelihood of corrosion. Moreover, a protective layer is commonly applied to the steel wire rods, such as oil or a corrosion-resistant coating. This coating acts as a barrier, preventing direct contact between the metal and the surrounding environment. By inhibiting the oxidation process, it safeguards the rods from corrosive elements. During the handling process, it is crucial to use appropriate equipment such as cranes, forklifts, or other lifting devices to minimize the risk of physical damage. Any scratches or dents on the surface of the wire rod can compromise the protective coating and increase the chances of corrosion. Regular inspections are essential to identify any indications of corrosion or damage. If any issues are found, immediate measures should be taken to prevent further deterioration. This may involve reapplying the protective coating or treating the affected area with rust inhibitors. In conclusion, the storage and handling of steel wire rods follow specific practices to minimize the risk of corrosion. By storing the rods in a dry and well-ventilated area, elevating them off the ground, applying protective coatings, using appropriate handling equipment, and conducting regular inspections, the potential for corrosion can be significantly reduced.

- Q: What are the different transportation methods for steel wire rod?

- The different transportation methods for steel wire rod include trucking, rail transportation, and shipping via cargo vessels.

- Q: What are the main factors affecting the product innovation of steel wire rod?

- The main factors affecting the product innovation of steel wire rod include technological advancements, market demand, competition, government regulations, and environmental sustainability. Technological advancements play a crucial role in enhancing the quality, strength, and durability of steel wire rod. Market demand and competition drive manufacturers to continuously innovate and develop new products to meet customer needs and stay ahead in the market. Government regulations, such as safety standards and environmental regulations, also influence product innovation by setting requirements and guidelines that manufacturers must adhere to. Lastly, the focus on environmental sustainability has prompted the steel industry to develop innovative and eco-friendly products and processes, leading to further innovation in steel wire rod.

- Q: What are the common applications of low carbon steel wire rod?

- Low carbon steel wire rod has a wide range of applications due to its various beneficial properties. Some of the common applications of low carbon steel wire rod include: 1. Construction: Low carbon steel wire rod is widely used in the construction industry for various purposes. It is commonly used for reinforcing concrete structures such as beams, columns, and slabs. The high tensile strength and ductility of low carbon steel wire rod make it an ideal choice for reinforcing purposes. 2. Manufacturing: Low carbon steel wire rod is extensively used in manufacturing industries for the production of various products. It is commonly used for manufacturing nails, screws, bolts, and other fasteners due to its excellent formability and strength. Additionally, it is used in the production of wire mesh, wire ropes, and cables. 3. Automotive industry: Low carbon steel wire rod finds applications in the automotive industry as well. It is used for manufacturing parts such as springs, suspension systems, and tire cords. The flexibility, strength, and durability of low carbon steel wire rod make it suitable for these applications. 4. Agriculture: In the agricultural sector, low carbon steel wire rod is commonly used for constructing fences and wire mesh. It provides durability and strength to the fencing systems, ensuring the security of livestock and crops. Additionally, it is used for making trellises and support structures for plants. 5. Household applications: Low carbon steel wire rod is also used in various household applications. It is used for making hangers, racks, and shelves due to its ability to withstand heavy loads. Additionally, it is used for manufacturing kitchen utensils, wire baskets, and other household items. Overall, low carbon steel wire rod is a versatile material used in numerous industries and applications. Its properties such as formability, strength, and durability make it a preferred choice for various manufacturing and construction purposes.

- Q: How is steel wire rod used in the production of tire reinforcement materials?

- Steel wire rod is used in the production of tire reinforcement materials by being transformed into steel cords through a series of processes. These steel cords are then embedded in the tire's rubber to enhance its strength, durability, and resistance to punctures. The steel wire rod plays a crucial role in providing the necessary tensile strength and stability to the tire, making it suitable for high-speed applications and ensuring the overall safety and performance of the tire.

- Q: Can steel wire rod be used in the production of wire mesh?

- Yes, steel wire rod can be used in the production of wire mesh.

- Q: How does the brittleness of steel wire rod vary with different wire drawing processes?

- The brittleness of steel wire rod can vary with different wire drawing processes. Generally, the more intense the wire drawing process, the higher the brittleness of the steel wire rod. This is because the wire drawing process involves reducing the diameter of the wire rod, which can result in an increase in internal stress and dislocations within the material. These defects can make the steel wire rod more prone to fracture and reduce its overall toughness. However, with proper heat treatment and control of the wire drawing parameters, it is possible to minimize the brittleness and enhance the mechanical properties of the steel wire rod.

Send your message to us

Steel Wire Rods Hot Rolled High Carbon First Class Quality Best Seller

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 20000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords