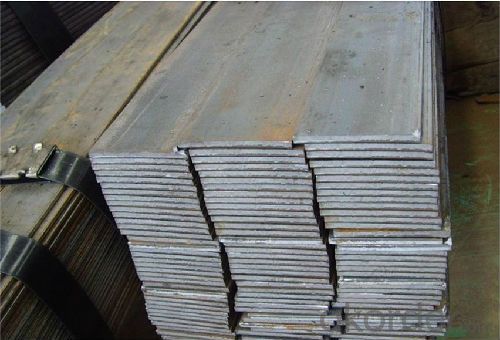

Wide flat bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

OKorder is offering Wide flat bar for construction made in China at great prices with worldwide shipping. Our supplier is a world-class manufacturer of steel, with our products utilized the world over. OKorder annually supplies products to European, North American and Asian markets. We provide quotations within 24 hours of receiving an inquiry and guarantee competitive prices.

Product Applications:

Wide flat bar for construction made in China are ideal for structural applications and are widely used in the construction of buildings and bridges, and the manufacturing, petrochemical, and transportation industries.

Product Advantages:

OKorder's Wide flat bar for construction made in China are durable, strong, and resist corrosion.

Main Product Features:

· Premium quality

· Prompt delivery & seaworthy packing (30 days after receiving deposit)

· Corrosion resistance

· Can be recycled and reused

· Mill test certification

· Professional Service

· Competitive pricing

Product Specifications:

Specifications of Bearing Steel Round Bar

Grade | AISI 52100, ASTM E52100, DIN 1.3505,JIS SUJ2, GCr15 |

Dimensions | Diameter: 30-60mm Length: 2000-13000mm or as required |

Shape | Round Bar |

Type | Alloy Steel Bar |

Delivery Condition | Black Surface |

Material | Bearing Steel |

Technique | Hot Rolled |

Usage and Applications of Bearing Steel Round Bar

Bearing steels are used for ball and roller bearing applications and are comprised of low carbon steels and high carbon through harden able steel.

First the famous 1C-1.5Cr steel from which the majority of bearings are made. Its structure is apparently well-understood and the focus is on purity in order to avoid inclusions which initiate fatigue during rolling contact. Then there is the M50 steel and its variants, from which bearings which serve at slightly higher temperatures in aeroengines are manufactured, based on secondary-hardened martensite.

Tapered roller bearing are generally used to support combined load mainly consisting of radial load. Their cups are separable for easy assembling ,During mounting and using, radial clearance and axial clearance can be adjusted and preloaded mounting can be made.

Packaging & Delivery of Bearing Steel Round Bar

Packaging Detail: ASTM 52100 Steel in seaworthy packing or on customer request; Packed in bundles with standard export sea-worthy package or as customer require

Delivery Detail: 45 days after confirmed

Trade terms: FOB, CFR, CIF ou as customer's required

MOQ: 25 tons or at customer's demands. If the quantity is good, the price will be better.

Processing of Bearing Steel Round Bar

The processing of Bearing Steel Round Bar is hot rolled (strictly control sulphur, phosphorus and non-metallic inclusions content and distribution)

Chemical Composition of Bearing Steel Round Bar

C | Si | Mn | Cr | Ni | Cu |

Equal or less than | |||||

0.95-1.05 | 0.15-0.35 | 0.25-0.45 | Cr:1.40-1.65 | 0.30 | 0.25 |

All products' chemical composition and specification can be design according to customers' requirement.

Note of Bearing Steel Round Bar

1. According to national standard (GB) for our products, if not, supply according to national standards (GB) or agreement.

2. We can not only provide electric furnace +LF+VD and electros lag re-melting (ESR) steel forging materials, but also forging products of piece, bar, etc.

3. Our company is equipped with roll equipment and can provide our customers with roll billets or finished.

4. Please send us your detailed specifications when inquire. We will reply to you ASAP.

5. Certificate of quality is issued in English, in addition the normal terms, production process, the mechanical property (yield strength, tensile strength, elongation and hardness. forged ratio, UT test result, Grain size, heat treatment methods and the sample of is shown on the certificate

FAQ:

Q1: How soon can we receive the product after purchase?

A1: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Q2: Can stainless steel rust?

A2: Stainless does not "rust" as you think of regular steel rusting with a red oxide on the surface that flakes off. If you see red rust it is probably due to some iron particles that have contaminated the surface of the stainless steel and it is these iron particles that are rusting. Look at the source of the rusting and see if you can remove it from the surface.

- Q: How does special steel perform in high-pressure environments?

- Special steel performs exceptionally well in high-pressure environments due to its high tensile strength, excellent corrosion resistance, and ability to withstand extreme temperatures. Its superior mechanical properties make it highly suitable for applications such as oil and gas pipelines, pressure vessels, and offshore drilling equipment, where it can effectively handle the intense pressures and maintain structural integrity even under harsh conditions.

- Q: What are the main applications of special steel in the defense electronics?

- Special steel is used in defense electronics primarily for its exceptional strength and durability. It is commonly used in the manufacturing of critical components such as missile casings, armor plating, and submarine hulls. Its high resistance to corrosion and extreme temperatures make it suitable for harsh environments, while its electromagnetic shielding properties help protect sensitive electronic equipment from interference. Special steel's unique characteristics ensure the reliability and performance of defense electronics in various military applications.

- Q: What are the main factors affecting the cost of special steel?

- The main factors affecting the cost of special steel include the cost of raw materials, such as iron ore and other alloying elements, as well as the cost of energy required for the manufacturing process. Other factors include the complexity of production methods, the level of demand and supply in the market, transportation costs, and any additional costs associated with quality control and compliance with industry standards.

- Q: What is the role of special steel in the oil and gas industry?

- Special steel plays a crucial role in the oil and gas industry as it is used in various critical applications. It provides high strength, corrosion resistance, and durability, making it suitable for manufacturing drilling equipment, pipelines, valves, and offshore structures. Special steel's ability to withstand extreme conditions, such as high pressure and temperature, ensures the safety and reliability of oil and gas operations, ultimately supporting the efficient exploration, extraction, and transportation of these resources.

- Q: What is the cost difference between regular steel and special steel?

- The cost difference between regular steel and special steel can vary significantly depending on various factors such as the specific type of special steel, its grade, production techniques, and market demand. In general, special steel tends to be more expensive than regular steel due to its enhanced properties, specific alloy compositions, and specialized production processes. However, it is important to note that the cost difference may fluctuate and it is best to consult with suppliers or conduct market research for accurate and up-to-date pricing information.

- Q: How is bearing steel used in the manufacturing of bearings?

- Bearing steel is specifically designed for the manufacturing of bearings due to its high hardness, wear resistance, and excellent rolling contact fatigue strength. This type of steel is used to produce the inner and outer rings, as well as the rolling elements of bearings. It undergoes a specialized heat treatment process to enhance its mechanical properties and ensure proper microstructure. The use of bearing steel in manufacturing ensures the durability and longevity of bearings, allowing them to withstand heavy loads, high temperatures, and corrosive environments.

- Q: What are the main applications of special steel in the packaging industry?

- Special steel is widely used in the packaging industry for a range of applications. One of the main uses is in the manufacturing of packaging machinery, such as filling machines, sealing machines, and wrapping machines, where the high strength and durability of special steel components ensure smooth operation and longevity. Additionally, special steel is utilized for the production of packaging tools, like cutters, blades, and molds, which require resistance to wear and corrosion. The use of special steel in the packaging industry helps to enhance productivity, improve product quality, and ensure the safety and integrity of packaged goods.

- Q: Can special steel be used in the rubber manufacturing industry?

- Yes, special steel can be used in the rubber manufacturing industry. Special steel is often used to create molds, tools, and equipment that are used in the production of rubber products. It is valued for its strength, durability, and resistance to wear and tear, making it suitable for various applications in the rubber manufacturing process.

- Q: What is the impact of high temperature on the mechanical properties of special steel?

- High temperatures can significantly affect the mechanical properties of special steel. As the temperature increases, the steel's strength and hardness decrease, leading to reduced load-carrying capacity and increased susceptibility to deformation and failure. High temperature can also cause a decrease in toughness and ductility, making the steel more brittle and prone to fracture. Additionally, the expansion and contraction of the steel due to thermal cycling can induce stress and lead to thermal fatigue, further compromising its mechanical integrity. Therefore, it is crucial to consider the impact of high temperature on the mechanical properties of special steel when designing and operating systems that involve elevated temperatures.

- Q: How does special steel compare to other materials such as aluminum or titanium?

- Special steel boasts a unique set of advantages and characteristics when compared to materials like aluminum or titanium. Firstly, its exceptional strength and durability set it apart. With a higher tensile strength than aluminum and titanium, it is ideal for applications that require withstanding heavy loads or high-stress environments. This strength also ensures a longer lifespan by resisting wear and tear. Furthermore, special steel maintains its mechanical properties even at extreme temperatures. Unlike aluminum and titanium, which experience a significant decrease in strength at elevated temperatures, special steel retains its structural integrity, making it suitable for applications involving high temperatures or thermal cycling. In terms of cost-effectiveness, special steel often proves to be more affordable than titanium, especially in large-scale production. While aluminum is generally cheaper than special steel, it may lack the same level of strength or resistance to corrosion, limiting its applicability in certain industries. Additionally, special steel exhibits excellent machinability and can be easily formed into different shapes and sizes, allowing for greater design flexibility. This quality makes it suitable for various industries such as automotive, aerospace, construction, and manufacturing, where complex components or structures are required. Lastly, special steel showcases superior corrosion resistance compared to aluminum and titanium. It can be treated or coated to provide additional protection against rust and other forms of degradation, further extending its lifespan. In summary, special steel surpasses aluminum and titanium in terms of strength, durability, temperature resistance, and corrosion resistance. Its cost-effectiveness, machinability, and versatility make it a preferred material in various industries, where high-performance and reliability are crucial factors.

Send your message to us

Wide flat bar for construction made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords