Wholesale Wooden Grain Coating High Quality Aluminum Coil Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Wooden Grain Coating Aluminum Coil with High Quality

Material | Alloy Aluminum 6063,6061,6005 or customer nominated |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Colour | Any colour based on Standard Germany RAL Mark |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Press Machine | 500-4000 tons all together 64 press lines. |

Fabrication | 1. Windows and doors; 2. Drilling; 3. Bending; 4. Cutting; 5. etc. |

Certificate | ISO 9001 |

Moulding | 1. Using our moulds, no fee; |

2. Using customer drawing, opening mould, usually about 10~50 tons then the moulding can be refunded. | |

3. Mould cost is negotiable base on the order quantity | |

Capability | Annual output 100,000 tons |

2. Application of Wooden Grain Coating Aluminum Coil with High Quality

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Wooden Grain Coating Aluminum Coil with High Quality

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

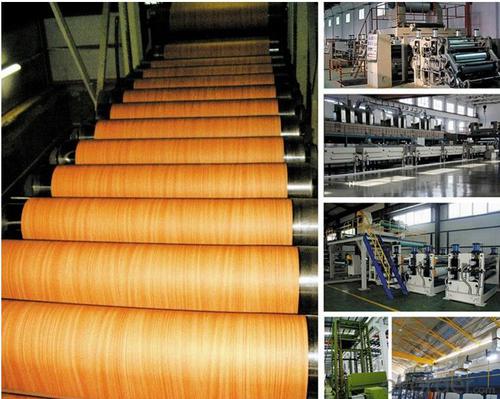

5. Image of Wooden Grain Coating Aluminum Coil with High Quality

6. Package and shipping of Wooden Grain Coating Aluminum Coil with High Quality

eye to wall

eye to the wall

with wood pallet (wooded case also available)

7. FAQ

1) What is the delivery time?

Dpends on actual order, around 20 to 35 days

2)What is the QC system:

We have QC staff of 20 persons and advanced equipment, each production is with MTC traced from Aluminum ingot lot.

3) What market do you mainly sell to?

Australia, America, Asia, Middle East, Western Europe, Africa etc

- Q: What are the transportation and storage requirements for aluminum coils?

- There are several factors that determine the transportation and storage requirements for aluminum coils. Firstly, it is crucial to handle the coils with caution during transportation in order to avoid any harm. Secure packaging is necessary to prevent potential scratches, dents, or deformation. Additionally, safeguarding the coils from moisture is essential as exposure to water or high levels of humidity can result in corrosion. During transportation, it is advisable to employ appropriate vehicles or containers that can sufficiently support the weight and dimensions of the aluminum coils. The coils should be firmly secured to prevent any movement or shifting that may cause damage. Regarding storage, it is of utmost importance to store aluminum coils in an area that is clean, dry, and well-ventilated. Ideally, the storage facility should maintain a stable temperature and humidity level to prevent any negative effects on the coils. If the coils are stored outside, they should be adequately covered and protected from direct sunlight, rain, and other weather conditions. Furthermore, it is crucial to store aluminum coils away from any substances or chemicals that may cause damage. They should be stored in a manner that prevents contact with other materials, as physical contact can lead to scratching or other types of damage. In summary, the transportation and storage requirements for aluminum coils involve careful handling, protection from moisture and corrosive materials, proper packaging and securing during transportation, and storage in a clean and suitable environment. By adhering to these guidelines, the integrity of the aluminum coils can be preserved, ensuring their quality and usability.

- Q: Can aluminum coils be customized in terms of thickness?

- Aluminum coils can indeed undergo customization in terms of thickness. The specific requirements of a particular application can determine the adjustment of aluminum coils' thickness. This customization is attained through the process of aluminum coil slitting, which involves cutting the original coil into narrower coils of the desired thickness. This method enables the flexibility to meet a range of needs and specifications across diverse industries.

- Q: Can aluminum coils be used in the manufacturing of lighting fixtures?

- Yes, aluminum coils can be used in the manufacturing of lighting fixtures. Aluminum is a lightweight and durable material that is commonly used in various industries, including the lighting industry. It offers excellent heat dissipation properties, making it suitable for fixtures that generate heat, such as LED lights. Additionally, aluminum coils can be easily shaped and molded into different designs, making them a versatile choice for lighting fixture production.

- Q: Aluminum reacts with water so why is it used in buildings and cooking??Some help by today would be good!! :DThanxx

- Aluminum reacts with water under certain conditions, but cookware does not usually present any of those conditions. Aluminum cookware takes advantage of the oxidizing process, which creates a natural protective layer over the aluminum. It doesn't react with water in the same way that chemical equations say it will because cooking surfaces are designed to maximize the oxidation effect. This is basically the same reason why aluminum foil doesn't react in water. In building materials, it's less about exposure to the elements and more about how cheap and lightweight it is. Many building materials are aluminum alloys, which makes them more susceptible to corrosion than purer aluminum, and the use of aluminium roofing material, though fairly corrosion-resistant by itself (for the same reasons as cookware), gets compromised by the proximity of other metals used in construction, like non-stainless steel nails and screws, for example, or copper pipes without insulation. The trade-off is that aluminium alloys hold their shape better and have greater tensile strength, some of which approach that of steel.

- Q: How do aluminum coils contribute to fire safety?

- Fire safety is greatly enhanced by the presence of aluminum coils. Primarily, aluminum is a material that does not burn or support combustion, making it an ideal choice for industries where fire safety is of utmost importance, such as construction. In the manufacturing sector, aluminum coils are commonly utilized to create fire-resistant barriers and protective claddings. These barriers function as a shield, effectively halting the spread of flames and heat across different sections of a building. By containing the fire and preventing its spread, aluminum coils play a pivotal role in limiting the destruction caused by fires and ensuring the safety of individuals. Moreover, aluminum coils are frequently employed in the fabrication of fire-resistant doors, windows, and curtain walls. These components are specifically designed to endure high temperatures and serve as an effective barrier against the propagation of fire and smoke. By utilizing aluminum coils as the fundamental material for these products, they can offer superior fire protection and help prevent the rapid advancement of flames in the event of a fire. Additionally, aluminum possesses excellent thermal conductivity in addition to being non-combustible. This characteristic enables it to swiftly dissipate heat, reducing the risk of ignition and minimizing the potential for fire accidents. Aluminum coils are often incorporated into heat exchange systems, such as HVAC units and refrigeration systems, where their thermal conductivity aids in temperature regulation and prevents overheating, further reducing the risk of fire. In conclusion, aluminum coils make significant contributions to fire safety by virtue of their non-combustible nature, their ability to serve as fire-resistant barriers, and their use in the production of fire-resistant doors and windows. Their capacity to dissipate heat rapidly also plays a crucial role in minimizing the risk of fire accidents. By employing aluminum coils in various fire safety applications, we can enhance the protection of buildings and ensure the safety of individuals in the event of a fire.

- Q: Can aluminum coils be used for roofing?

- Certainly, roofing can be done using aluminum coils. Aluminum is widely regarded as a top preference for roofing materials because of its sturdy composition, lightweight properties, and exceptional resistance to corrosion. In a wide range of roofing applications, including residential, commercial, and industrial structures, aluminum roofing coils are frequently employed. They offer exceptional safeguarding against severe weather conditions like intense rainfall, snowfall, and powerful winds. Furthermore, aluminum coils possess energy-efficient attributes as they possess the ability to reflect solar heat, thereby aiding in preserving a cool indoor environment and reducing energy expenditures. All in all, aluminum coils present a dependable and enduring roofing solution.

- Q: How are aluminum coils tested for quality?

- To ensure compliance with the necessary standards, a variety of methods are employed to test the quality of aluminum coils. Trained personnel conduct visual inspections to identify any visible defects, such as scratches, dents, or surface imperfections. Likewise, dimensional inspections are carried out, utilizing precision instruments to measure the thickness, width, and length of the coils. This guarantees that the coils are manufactured within the specified tolerances. Furthermore, mechanical testing is performed to evaluate the strength and durability of the aluminum coils. Tensile and yield strength tests measure the maximum load a coil can endure without breaking or deforming, while bend tests assess flexibility and resistance to cracking. Moreover, chemical composition analysis is conducted to verify the purity and consistency of the aluminum material. Spectroscopy techniques, such as atomic absorption or emission spectroscopy, are commonly employed to determine the exact elemental composition of the coils. Coating tests are also conducted to assess the quality of any protective or decorative coatings applied to the aluminum coils. These tests include adhesion testing, corrosion resistance testing, and evaluation of color consistency. In addition to these conventional methods, advanced non-destructive testing techniques are utilized to detect any internal flaws or defects in the coils. Ultrasonic testing, eddy current testing, and X-ray inspection are employed to identify hidden defects without causing damage to the material. Ultimately, a combination of visual, dimensional, mechanical, chemical, and non-destructive tests ensures that aluminum coils meet the necessary quality standards before being utilized in various industries, such as construction, automotive, or electronics.

- Q: This question asks for a brief explanation of the process involved in the manufacturing of aluminum coils.

- <p>Aluminum coil is made through a series of processes starting with the melting of aluminum ingots or scrap. The molten aluminum is then poured into a casting machine where it's cooled and solidified into large slabs. These slabs are then heated and passed through a series of rolling mills to reduce their thickness and achieve the desired coil gauge. The rolling process is often hot or cold, depending on the final application of the coil. After rolling, the aluminum is coiled into rolls and may undergo additional treatments like annealing to improve its properties. Finally, the aluminum coil is cleaned, inspected, and shipped for use in various industries such as construction, automotive, and packaging.</p>

- Q: Are aluminum coils suitable for interior design applications?

- Yes, aluminum coils are suitable for interior design applications. Aluminum is a versatile material that offers durability, lightweight properties, and resistance to corrosion. It can be easily shaped, painted, or coated to match various design aesthetics. Additionally, aluminum coils are commonly used for decorative purposes like ceiling panels, wall cladding, and furniture components, making them a popular choice in interior design projects.

- Q: What is the typical conductivity of aluminum coils?

- The typical conductivity of aluminum coils is relatively high, with values ranging from 34 to 38 million Siemens per meter (MS/m) at room temperature. Aluminum is known for its excellent electrical conductivity, which is why it is widely used in various electrical applications, including power transmission lines, electrical conductors, and coils. This high conductivity allows for efficient and effective flow of electric current through aluminum coils, making them suitable for conducting electricity in a reliable and efficient manner.

Send your message to us

Wholesale Wooden Grain Coating High Quality Aluminum Coil Roll

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords