Whole Aluminum Formwork with Different Sizes Used in Large Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

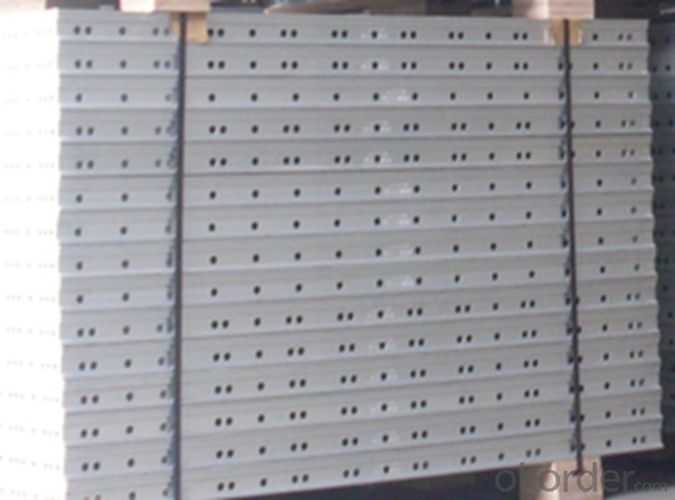

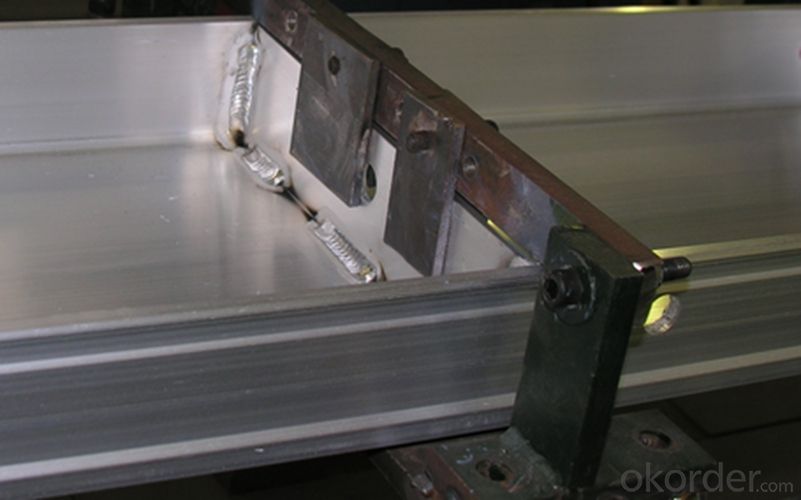

3. Whole Aluminum Formwork Images

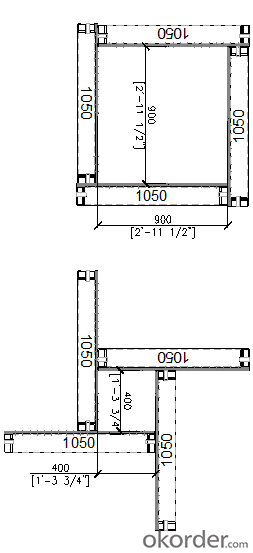

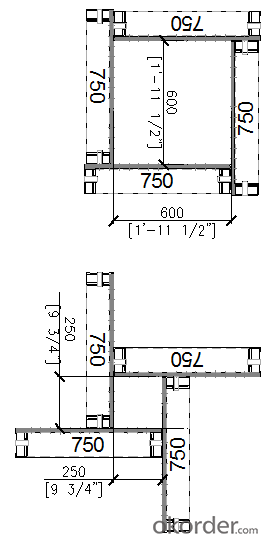

4.Whole Aluminum Formwork Specifications

1) MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2) DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3) StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4) StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

We can provide you the professional technical team.

We can provide professional building proposal for your projects.

Please feel free to customize.

2) What promises can be done by us?

If interested in this kind of formwork, please feel free to write us for any QUOTE.

If need any technical and building assistance, we could provide on-site professional staff for instruction.

Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale services?

Response will be carried out in 24hours after receiving any complain or request.

- Q:What is a door rack for a construction site? How high is it generally?

- Door scaffolding has not yet unified design and product standards, the products of different specifications, quality is inconsistent. Not only for construction units to use and management of great difficulties, is not conducive to the promotion of applications, but also to the construction safety risks. Therefore, it is necessary to organize and issue a unified standard for door scaffolding

- Q:What functions should be achieved in mechanical structure design?

- Mechanical structure design plays an important role in mechanical design. This chapter mainly discusses the characteristics, steps and mode of thinking of mechanical structure design. The working principle and design requirements of the machine assembly is a major factor in determining the structure and shape of the parts, followed by the selection of materials, manufacturing process requirements, which has the advantages of good manufacturability (processing and assembly). In addition, the perfection of the structure and shape of the parts has a great influence on the strength and stiffness.

- Q:What measures can effectively reduce the construction accident rate?

- Hefei construction workers training _ fail safe design: in the part of the system, equipment malfunction or damage, can also ensure the safety of safety and technical measures known as fault - Safety Design in a certain period of time (fail-safe). Generally speaking, through careful technical design, the system and equipment are in a low energy state when the fault occurs, thus preventing the unexpected release of energy. For example, a fuse in an electrical system is a typical fault - Safety Design; when the system is overloaded, the fuse is fused and the circuit is disconnected to ensure safety. Although the fail safe design is an effective measure of safe technology, but considering the fail safe design itself may not work due to failure, so the choice of safety technical measures should not give priority to the use of.

- Q:What are the sectors of machine building and parts processing?

- 1., industry generally refers to its production of similar products, or with the same process, or to provide similar labor services division of economic activities, categories.

- Q:What are the details of construction machinery parts in sand casting?

- (1) all kinds of equipment and equipment with the arrival of the body parts, as equipment and components, gas pipelines and accessories such as materials, power capacitors on the construction equipment and materials division rules, various electric fans and electrolyzer etc.. 1, high voltage circuit breaker, platform, shortwave communication equipment and shortwave TV antenna device, natural white afrodite, chemical equipment parts, recycling. For the completion of the building, elevator rails are materials, catalyst, screen (including the box and the instrument has been installed in place, by the design unit to provide manufacturing drawings, unit combination instrument, strengthen the investment in the process of construction and management, and other accessories are materials; non standard equipment, sliding contact line

- Q:Where does Heilongjiang do the most construction machinery?

- In the world, the industry address basic similar, of which the United States and Britain called the construction machinery and equipment, construction machinery and equipment for Germany, Russia called for the construction and road construction machinery, construction machinery called japan. In China, some products are also known as construction machinery, and in the mechanical system, according to the State Council to set up the industry approval, collectively referred to as construction machinery, has continued to the present

- Q:What are the mechanical drawing software?

- Personally, CAD is suitable for large machines or buildings, and CAXA is the real machine industry's universal software, and can also save drawings in various formats.

- Q:Where was the construction machinery conference held in 2015?

- 2015 Bada international construction machinery exhibition, exhibition information time: June 5, 2015 (Friday) - 7 day (Sunday) location: Shandong Bada international engineering machinery City Theme: cooperation, win-win, innovation, development, guidance: National Quality Supervision and inspection center of engineering machinery, Shandong Machinery Industry Association, Shandong province transportation and Logistics Association Shandong, Shandong Jiaotong University, Shandong Institute of road, economic development zone of Qihe Province

- Q:China mechanical net

- There are mechanical product development and design, mechanical equipment transformation, mechanical equipment maintenance, data inquiries, standard inquiries, mechanical professional translation, mechanical CAD and other mechanical and technical services.

- Q:Where are the mechanical pressurization air supply facilities set up?

- The purpose of setting up a mechanical pressurization air supply smoke prevention system is to provide evacuation routes and shelters without smoke interference in the event of a fire in the building. Therefore, in the closed door, pressing position, and the fire floor must maintain a certain pressure difference, the position of the air pressure value is a relative positive pressure); at the same time, in the open part of the pressure when the door can have enough air velocity in the opening section, to effectively prevent the intrusion of flue gas, the safety of personnel ensure evacuation and refuge.

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Whole Aluminum Formwork with Different Sizes Used in Large Projects

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 10000000 m²/month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords