Whole Aluminum Formwork System For Large Area Slab Formwork System

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Whole Aluminum Formwork Description

Whole Aluminium Formwork System is designed to reduce material quantity, erection and dismantling time as well as effort, subsequently increasing efficiency and reducing general construction time, materials and labour cost. All main components are manufactured from high grade aluminium alloy. This structural grade aluminium has exceptional properties being extremely light in weight but also heavy-duty and durable. When incorporating this into a design which utilizes standard components and allows several possible plan and elevation variables, it provides a lightweight solution for a large area slab formwork system.

2. Main Features of Whole Aluminum Formwork

-Light and easy assemble

-Simple structure.

-Competitive prices

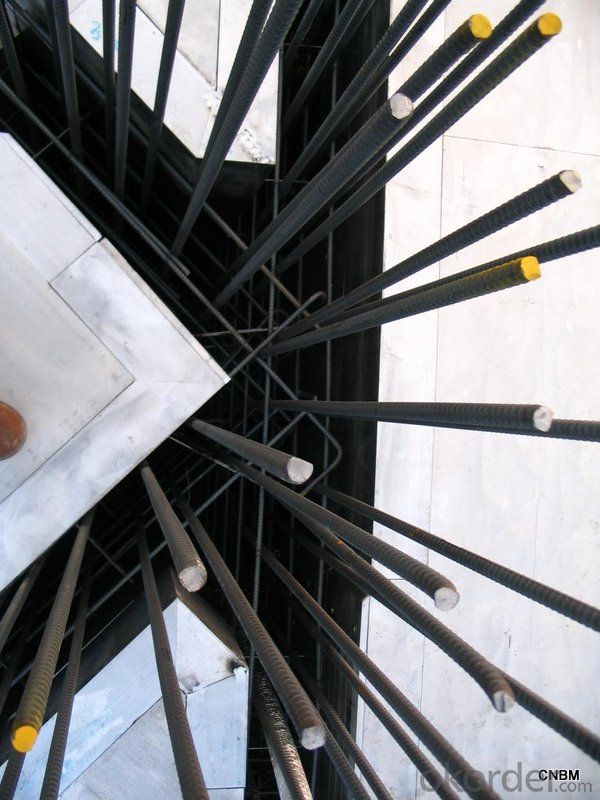

3. Whole Aluminum Formwork Images

4. Whole Aluminum Formwork Specifications

1: MaximumColumn Size:900 x 900mm

(2’-11.5”x 2’-11.5”)

2: DesignConcrete Pressure: 1,800 psf (90 kN/m2)

3:StandardPanel Width 900mm, 750mm & 600mm

(2’-11.5”,2’-5.5” & 1’-11.5”)

4:StandardPanel Height: 3.0m, 2.4m, 1.2m

5.FAQ of Whole Aluminum Formwork

1) What can we do for you?

.We can ensure the quality of the Whole Aluminum Formwork and avoid extra expenses for customers.

.We can provide you the professional technical team.

.We can provide professional building proposal for your project.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in this kind of formwork, please feel free to write us for any QUOTE.

. If need any technical and building assistance, we could provide on-site professional staff for instruction.

. Please DO check goods when courier knocks your door and contact us asap if any issueS.

3) What about of our after-sale services?

. Response will be carried out in 24hours after receiving any complain or request.

. Any formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

-Packing: wood package and adhesive tape

-Shipping: by sea

-Shipping time: Normally small orders just takes 7 business days to arrive your hand;. When it comes to the customs declaration, it may need 2weeks.

Ten superiorities in Aluminum Formwork

1.Environmental Protection.

2.Low using cost.

3.Saving labor & Easy installation.

4.Fast speed of construction.

5.Recycling 300 times.

6. High stability and load bearing capacity.

7. Safety & convenience.

8. Recovery of high value.

9. Strong versatility.

10. Precision design & compact joint.

Introduction of Aluminum Formwork System

| Material | 6061-T6 Aluminum alloy |

| Main Components | Wall |

| Beam | |

| Column | |

| Prop | |

| Others | |

| Applications | Exhibition setup |

| Interior refurbishing | |

| All the towers can be connected together for multi-purpose | |

| Yield strength | ≥30KN/m2 |

Size | Non-standard, custom-made as per buy's request |

| Features | Easy to Handle |

| High Concrete Pouring Rate | |

| More Reuses | |

| Great Recyclable Value | |

| Environmental Friendly | |

| One-time Pouring |

- Q: What are the mixing arms of the concrete mixer?

- Mixing arm concrete mixer is a component of the mixing arm itself and divided into lateral mixing arm (positive and negative points), stirring arm (also have positive and negative points), stirring arm below is the bearing seat connected, connected with 4 sets of high strength bolts with stirring arm. The top is equipped with wear-resistant mixing blades, connecting with mixing blades, high-strength bolts 2 sets. In addition, some manufacturers have designed mixing side bonded shaft swivel, is installed in the interval between the stirring arm fixed and rotated in two ways.

- Q: What are the details of construction machinery parts in sand casting?

- Lighting distribution box and other small appliances, slot box, detection control device, air inlet, bell, industrial TV, muffler and its components, dust removal equipment, and the communication line at the same time, a combination of the components installed. (4) refractory used for masonry at site.

- Q: Changsha Sanlian Building Machinery Fittings Factory

- The company in Changsha Hongdun business online can not find, provided by his address: two Changsha section of Xingsha Economic Development Zone Yuan Ming Road, I checked 114 specially call 12580 to booking the hotel near the road, not the road. Definitely a liar.

- Q: How are the machine parts stacked?

- Then there is a point to note, that is, from there to get used, must be put back where, so that will be organized, all things are owned by you, it will not mess.

- Q: What are the safety protection equipment, machinery and equipment, construction machinery and accessories for construction enterprises?

- As well as scaffolding, protective fence, all belong to the safety protection facilities, does not belong to the safety protection appliances. Safety protection tools are many, it is characteristic of the operator to carry, I will not list

- Q: What are the mechanical drawing software?

- Personally, CAD is suitable for large machines or buildings, and CAXA is the real machine industry's universal software, and can also save drawings in various formats.

- Q: What are the world famous mechanical equipment exhibition?

- 2 、 Las Vegas Construction Machinery Exhibition (Conexpo-Con/Agg) sponsored by the American equipment manufacturers association, the American precast concrete association, the United States sand association. It is the world's second largest construction machinery exhibition after BAUMA. The exhibition, sponsored by the American Association of equipment manufacturers, has been held every three years for nearly a hundred years. The next exhibition will be held on March 2017 7-11. The exhibition is of great size and numerous merchants. It has focused on world famous brands such as Caterpillar, Komatsu, Liebherr and Volvo. It is an important platform for displaying the latest technology, equipment and products in the industry.

- Q: Construction machinery production need to deal with what documents?

- The person in charge of the enterprise, the person in charge of the project, full-time safety management personnel in "safety assessment qualified" column content according to the "three persons" Safety Assessment Certificate (fill in the contents of enterprise work safety management staff should meet the enterprise production safety management, the safety management department staff with the qualification to the total contract for not less than 5, not less than 3 professional contracting labor subcontracting, not less than 1; the construction site should be equipped with full-time safety management personnel according to the project size can be determined, according to the construction area of less than 10 thousand M2 project has at least a part-time staff of more than 10 thousand M2; project 1 - 2 full-time staff; more than 50 thousand M2 large sites, according to different professional safety management group);

- Q: What are the construction materials, components, fittings and equipment in construction?

- Board: cast-in-place slab, prefabricated slab, prefabricated hollow slab, reinforced concrete slab, wood board. The wall, brick wall, concrete wall, roof parapet, wall light. Door: solid wood door, plywood door, steel door. Window: window, wooden window, Aluminum Alloy window, plastic steel window. The building is in addition to other parts of the building and construction of houses built some auxiliary components, such as scaffolding, construction with pipe thread adjuster, building rod, triangle construction support, reinforced joints etc..

- Q: What is the difference and connection between equipment manufacturing and machine building?

- In accordance with the standards of classification, including metal products, general machinery manufacturing, machinery manufacturing, transportation equipment manufacturing, electronic and communication equipment manufacturing industry, electrical machinery and equipment manufacturing, instrumentation and office machinery manufacturing seven deducted 186 small consumer related manufacturing industry after class. Equivalent to the European countries referred to as "capital goods manufacturing", that is, we often say "the production of means of production industry."".

Send your message to us

Whole Aluminum Formwork System For Large Area Slab Formwork System

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 pc

- Supply Capability:

- 10000000 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords