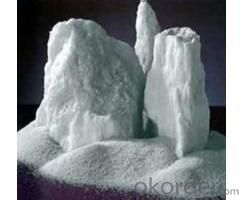

Raw Materials for Refractory - White Fused Alumina 99.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | 25kg bag or ton bag or as your requirement. |

| Delivery Detail: | within 20 days delivery after receipt of advance payment. |

Specifications

99% high purity abrasive White fused alumina for refractory

1.White fused alumina99%

2.Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm

Products discription

1.Introduction

The main raw material of white fused alumina is high grade processed alumina, which is fused with the carbon material and scrap iron in the electic furnace under the high temperature of above 2200°C.The product is characterized by low expansion coefficient, high refractoriness, good thermal and chemical stability.

2. Grain size commonly used

Refractory: 0-1mm, 1-3mm, 3-5mm, 5-8mm ,200#-0, 325#-0.

Abrasives: F24-F60.

Sandblasting abrasive:F10-F240.

Precision casting: F80-100, F100-F120.

Ceramic & electronic polishing:F240-800.

3.Physical properties of White Fused Alumina

Item | Color | Color System | Mohs Hardness | Melting Temperature(°C) | Refractory Temperature(°C) | True Density( g/cm3) | Magnetic Material |

Specification | white |

trigonal system | min10 | 2250°C | 1900°C | min3.50 | max0.003%

|

4.Chemical index of White Fused Alumina

Purpose | Specification | Chemical composition(%) | Magnetic material content(%) | ||||

Al2O3 | Na2O | SIO2 | CaO | ||||

For abrasive | F | 12#—80# | min99 | max0.6 | max0.4 | max0.003 | |

90#—150# | min98.5 | max0.003 | |||||

180#—240# | min98.2 | max0.7 | max0.4 | max0.002 | |||

For refractory | Size sand | 0—1mm | min99 | max0.5 | max0.4 | max0.003 | |

1—3mm | |||||||

3—5mm | |||||||

5—8mm | |||||||

Fine powder | 200#—0 | min98.5 | max0.5 | max0.5 | max0.003 | ||

325#—0 | |||||||

- Q: How many kinds of refractory materials are there in the EI?

- I suggest that you contribute articles to foreign SCI journals for the odds are better, and generally the articles that fill the bill will not be rejected. The traditional refractory materials can contribute to EI journal. If being rejected by EI journal, you can also contribute to Russia's journal Industrial Ceramics and Refractories. I didn't contribute to the Journal of Wuhan University of Science and Technology, the receiving cycle is almost 3 to 4 months. Though the impact factor is low, domestic EI journal is not so good, it is still SCI journal. This is my own experience, please take my advice. The best journals are the Journal of the American Ceramic Society and the Journal of the European Ceramic Society, I heard that they are not bad. But the best domestic EI refractory material journal is the Journal of The Chinese Ceramic Society. It is very long, but if it belongs to your university, it is another pair of shoes. Journals now all want to have materials about functional ceramics, and they don't want Chinese articles, if your English is not well enough, you can choose Ceramics International and Japan Ceramics but they have strict manuscripts reviewing standards.

- Q: The fire prevention board line is made of what material?

- Crural line: wooden, in the market, there are sjoiner woodblock, peach wood and artificial engraving. The second classification is stone and the most used one is the marble graved or ceramics well-made one is taken as the first choise. Its price is a little bit expensive than the wooden one, but also a suitable choise. Condole supports: It has various category. The general furniture choose plaster and anti-firing plate and the other also have a choice of steel. You can make a suitable choice according to the need. If it is contracting project, it depends on your project specific plan and funds plan. In a word, beauty and harmony should be given priority since it is the source of design.

- Q: What brands are the best in the A-level refractory materials?

- 1 International (It is a well-known brand in the field of global boats and protective coatings, the products are famous for its safety, strength and smoothness, Akzo Nobel (China) Investment Co., Ltd.) 2 LANLING (It is a high-tech enterprise, and a large provider of industrial coatings, started in 1980, as well as a famous brand of Jiangsu Province, Jiangsu Lanling Chemical Group Co., Ltd.) 3 Champion (It is a high-tech enterprise who is involved in developing a number of industry standards, it is a industry-leading brand brand of Jiangsu Province Jiangsu champion coating Technology Group Limited) 4 BBMG Coating (It is a large coating enterprise and a leading brand of fire-resistant coating who draft up the fireproof coating industry standards, Beijing BBMG Coating limited liability company) I hope my answer can help you .

- Q: What are the requirements of refractory temperature of refractory brick?

- Refractory bricks furnace pipe material is generally divided into two types, namely, shapeless refractory material and shaped refractory. Shapeless refractory material, also known as castable refractory, is hybrid powder material made up of many kinds of aggregate or aggregate and a kind of or many kinds of binders. It must cooperate and evenly stir with a kind or many kinds of liquids during use and has strong mobility. Shaped refractory material usually refers to refractory brick whose shape has standard rules. It can also be processed temporarily during cutting according to requirement. Refractory brick, called refractory brick for short, is refractory material made by firing refractory clay or other refractory raw materials. Faint yellow or brownish, it is mainly used in building smelting furnace. It can resist 1,580 ℃-1,770 ℃ high temperature.

- Q: Does anyone know about the fire resistance period of thin fireproof coatings?

- The columns are 2.5 to 3.0 hours, beams are 2.5 hours, C-shaped steels are 0.5 hours. The thin steelwork fireproof coatings are primarily water-soluble, which will be expanded and foamed when exposing to the fire. Thus the fire-resistant insulation layer formed through expansion and foaming will delay the temperature increase of the steel and protect of steel components. The thin fireproof coatings are made of adhesives, catalysts, carburizers, foamers, fillers, fibers and modifiers. The required emulsion polymers must have good adhesion, durability, and water-resistance to the steel substrates. The coating has a strong adhesion and good flexibility, is light and thin, as well as highly resistant to vibration. It is especially applicable for indoor bareness steel structure, light layer steel structure, and steel structure with decoration demands whose fire resistance requirement is within 1.5-2.5 hours.

- Q: How many refractories are there for boiler above 1200 ℃?

- In addition to refractory brick, refractories include refractory concrete (refractory cement+aggregate), fire-resistant insulating layer (refractory cement+vermiculite powder or refractory cement + diatomaceous earth) and the like. Refractories often used are azs brick, corundum brick, direct-bonded?magnesia-chrome?bricks, carborundum brick, silicon nitride bonded silicon carbide brick, nitride, silicide, sulfide, boride, carbide and other nonoxide refractory materials, calcium oxide, chromium hemitrioxide, aluminium oxide, beryllia and other refractories. Thermal insulation refractory materials often used are diatomite product, asbestos product, insulation?board,etc. Unshaped refractories often used are repairing?mass, ramming?mass, castable refractory, plastic refractory, refractory mortar, refractory gunning mix, sling refractory, refractory coating, lightweight refractory?castables, stemming, etc.

- Q: What are the main characteristics of the sic refractories?

- 1. The usge temperature of silicon carbide refractory is generally 1760 ℃ 2. The silicon carbide refractories can withstand the dramatic changes of temperature and have a good thermal shock resistance performance. To prevent the cracking or breaking of lining refractories. 3. Under the conditions of high or low temperature, it can withstand a certain compressive stress. 4. Under the conditions of high or low temperature, it can withstand friction. 5. It can withstand the huge hydraulic pressure or buoyancy of the metal. 6. It can also withstand the effect of furnace gases to prevent the infiltration of other refractories and reactions.

- Q: how to classify Insulating Refractory ?

- We are glad to answer your questions! This one is professional. My advice is to go through relevant webs for reference.

- Q: What are the material requirements of class A fire resistant door ?

- Refractory time should be no less than 1.5 hours.

- Q: Can the teflon material resist fire?

- Teflon does not burn and with the ability of flame retardant.

Send your message to us

Raw Materials for Refractory - White Fused Alumina 99.5%

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords