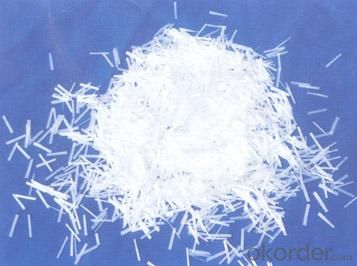

Wet Fiberglass Chopped Strands Mat Tissue

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000kg kg

- Supply Capability:

- 200000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

Wet Chopped Strands are compatible with unsaturated polyester, epoxy and phenolic resins and gypsum.

Wet Chopped Strands have moderate moisture content and deliver outstanding flowability, including dispersion in water and in gypsum.

2.Product Features:

Excellent dispersion in water

Good bonding with multiple resins

Outstanding tensile and tear properties in the final product

3.Product Specifications:

Property | Fibre diameter | Moisture Content | Size Content | Chop |

(%) | (%) | (%) | (%) | |

Mathods | IS01888 | ISO3344 | ISO1887 | |

3mm | ±10 | ≤3.0 | 0.1±0.05 | 98 |

6mm | ||||

12mm | ||||

18mm |

Special specification can be produce according to customer requirements.

4.FAQ

a.Packaging:

Each bag can be taken (15-25kgs)。 Could also take a big container bag.

b.Storage:

Unless otherwise specified, It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

- Q: Can fiberglass mat tissue be used for insulation in oil refineries?

- Yes, fiberglass mat tissue can be used for insulation in oil refineries. It is commonly used due to its excellent thermal insulation properties, resistance to high temperatures, and resistance to chemical corrosion.

- Q: Can fiberglass mat tissue be used for insulation in refrigeration systems?

- Yes, fiberglass mat tissue can be used for insulation in refrigeration systems. Fiberglass is a common material used for insulation due to its excellent thermal properties and resistance to moisture. Fiberglass mat tissue is specifically designed to provide insulation and is often used in the construction of refrigeration systems. It helps to minimize heat transfer and maintain the desired temperature inside the system. Additionally, fiberglass is lightweight, durable, and easy to install, making it a popular choice for insulation in refrigeration systems.

- Q: How long does fiberglass mat tissue typically last?

- The duration of fiberglass mat tissue's lifespan is subject to fluctuation due to a variety of factors, including material quality, exposure to environmental conditions, and maintenance level. Typically, fiberglass mat tissue has a lifespan of 20 to 30 years. Nevertheless, by implementing appropriate installation techniques and consistent maintenance practices, it has the potential to endure beyond this time frame. It is crucial to emphasize that routine inspections and maintenance aid in the detection of any indications of deterioration or harm, permitting prompt repairs or replacements to guarantee its longevity.

- Q: What is the expected lifespan of fiberglass mat tissue?

- The lifespan of fiberglass mat tissue can differ based on several factors, including material quality, exposure conditions, and specific usage. Nonetheless, fiberglass mat tissue is renowned for its longevity and durability. When manufactured and installed correctly, fiberglass mat tissue has the potential to endure for many decades. It possesses resistance against decay, corrosion, and various chemicals, making it suitable for diverse industries and applications. Furthermore, fiberglass mat tissue is esteemed for its strength and capacity to withstand high temperatures. Nevertheless, it is crucial to acknowledge that prolonged exposure to harsh environmental elements, such as extreme temperatures, UV radiation, and moisture, may gradually degrade the material. Regular maintenance and appropriate care can aid in prolonging the lifespan of fiberglass mat tissue. In conclusion, while it remains challenging to determine an exact anticipated lifespan for fiberglass mat tissue, it is generally perceived as a long-lasting material when utilized and maintained properly.

- Q: What is the flexibility of fiberglass mat tissue at low temperatures?

- The flexibility of fiberglass mat tissue at low temperatures is generally maintained, as fiberglass has low thermal expansion and contraction properties, allowing it to retain its flexibility even in cold conditions.

- Q: Can fiberglass mat tissue be used for insulation purposes?

- Yes, fiberglass mat tissue can be used for insulation purposes. It is commonly used as a layer in insulation systems to provide thermal resistance and enhance the overall insulation performance.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Yes, fiberglass mat tissue must meet specific certifications and standards. These can include ASTM International standards such as ASTM D7055 for fiberglass mat used in roofing applications or ASTM C1667 for fiberglass mat used in gypsum panels. Additionally, the product may need to comply with industry-specific certifications like ICC-ES for construction materials or UL for fire resistance. Meeting these certifications and standards ensures the quality and performance of fiberglass mat tissue in various applications.

- Q: Can fiberglass mat tissue be used for insulation in cold climates?

- Yes, fiberglass mat tissue can be used for insulation in cold climates. It is a commonly used material for insulation due to its low thermal conductivity and ability to trap air, providing effective insulation against cold temperatures.

- Q: Is fiberglass mat tissue suitable for insulation in laboratories?

- Insulation in laboratories can be effectively achieved using fiberglass mat tissue. This material is widely used for thermal insulation due to its exceptional thermal properties. With its high resistance to heat transfer, fiberglass mat tissue serves as an efficient insulator, maintaining stable temperatures within laboratory spaces. Moreover, fiberglass mat tissue offers resistance against moisture, chemicals, and fire, all of which are critical factors in laboratory settings. It can withstand exposure to harsh chemicals without degrading or losing its insulating properties over time. Therefore, it is an ideal choice for insulation in laboratories where various chemicals and substances are handled. In addition, the installation of fiberglass mat tissue is hassle-free and can be tailored to meet specific insulation requirements. It can be easily applied to walls, ceilings, and pipes, creating a barrier that prevents the transfer of heat and ensuring a controlled environment within the laboratory. In summary, fiberglass mat tissue is a suitable option for laboratory insulation due to its thermal resistance, chemical resistance, fire resistance, and ease of installation. It aids in maintaining stable temperatures, safeguards against chemical exposure, and ensures safety in laboratory environments.

- Q: How does the surface finish of fiberglass mat tissue affect its adhesion to resin?

- The surface finish of fiberglass mat tissue can significantly affect its adhesion to resin. The surface finish refers to the texture or smoothness of the fiberglass mat tissue. In general, a rougher surface finish tends to provide better adhesion to resin. This is because a rough surface provides more surface area for the resin to adhere to, allowing for a stronger bond. Rougher surface finishes can be achieved through various manufacturing techniques, such as using coarser fibers or adding texturizing agents during production. On the other hand, a smoother surface finish may result in weaker adhesion. A smooth surface does not provide as much surface area for the resin to bond with, leading to a weaker and less durable bond. Smoother surface finishes can be achieved by using finer fibers or through additional processing steps to smooth out the surface. It is important to consider the specific application and requirements when choosing the surface finish of fiberglass mat tissue. For applications that require high strength and durability, a rougher surface finish may be preferred to ensure optimal adhesion to the resin. Conversely, for applications where a weaker bond is acceptable or where a smoother surface finish is desired for aesthetic reasons, a smoother surface finish may be chosen. Ultimately, the surface finish of fiberglass mat tissue plays a critical role in determining the adhesion to resin. It is essential to select the appropriate surface finish to achieve the desired strength, durability, and performance in various applications.

Send your message to us

Wet Fiberglass Chopped Strands Mat Tissue

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000kg kg

- Supply Capability:

- 200000kg Per Month kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords