Wear-resistant wpc vinyl flooring economical custom design wpc

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction of Wood Plastic Composite Decking

The WPC decking is a new material, combine the nature look of a wood deck with the advantages of a weather-resistant, stable, easy to clean, and sturdy high-tech material and quite follow the trend of wood substitute.

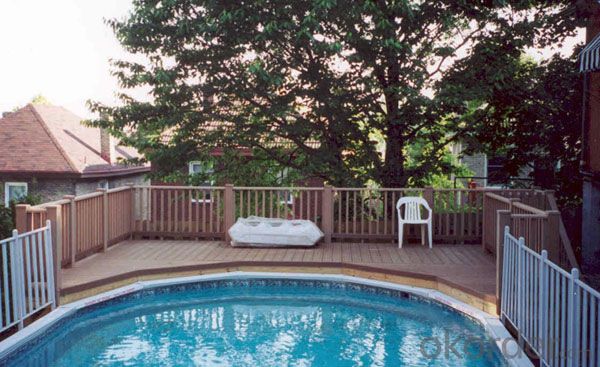

Application of Wood Plastic Composite Decking

widely used for outdoor decking floor,Wall panel.railing,fence,bridge,dock,gloriette,gazebo,boardwalk,etc

Advantage of Wood Plastic Composite Decking

1. With the look of the natural wood but less timber problems, Approx. 90% recycled materials

2. Weather resistant, suitable from -40 to 60 °C

3. Resistant to termite and insect attack, will not split, rot or warp

4. Cuts and drill like timber

5. Requires no painting, no glue, low maintenance effort

6. Easy to install and clean

Packing of Wood Plastic Composite Decking

Packaging Detail | 112pcs per pallet, 16pallets per 20ft, 24 pallets per 40ft. pallet size:290x105x1375px |

Delivery Detail | 15 days after received the deposit |

Pictures of Wood Plastic Composite Decking

Specification of Wood Plastic Composite Decking

component | 30%HDPE+60%bamboo/wood fiber component+10%chemical additives |

Length | 2.2m, 2.9m, and 5.8m or customized |

Size | 140X20mm,150X25mm,145 X21mm,145 X25mm, etc |

Surface treament | original, sanded, brushed |

Color available | 5 regular colors for choice ( IPE, Walnut, gray stone, Cedar, Rosewood) and we can adjust the new color according to the order requirement |

FAQ

We have organized several common questions for our clients,may help you sincerely.

1. How about your company?

Our company is a world class manufacturer & supplier of Wood Plastic Composite and is one of the large-scale professional investment Wood Plastic Composite bases in China. Annually more than 1000 containers of Wood Plastic Composite bases are exported to markets in Europe, North America.

2. How to guarantee the quality of the products?

We can supply certificates, including ISO9001, ISO14001, CE, FSC Certificate, "REACH" Test Reports by SGS; Intertek Test Report by ASTM standard..etc.

3. How to install the WPC decking?

Installation tool: electric saw (desk type or portable),churn drill, electric portable drill and driver

Decking and accessories: 1.decking 2.joist 3.metal clip 4. plastic expansion screws 5.start clip 6.fascia

Installation step:

1. Fix the joist. 2. Decking installation. 3.Fascia installation

- Q: What is the degree of wear resistance of the floor? What is the number of people talking about what is the meaning? The The More

- The degree of wear resistance of the composite floor is mainly expressed in revolutions, and the number of rotations is more than that of the double crystal. Now the new national standard, the number of domestic wear-resistant 2 can not be less than 4000 rpm, the number of home-level rotation can not be less than 6000 rpm, commercial grade is not less than 9000 turn, the home without the need to pursue high wear speed , As long as the national standard can be achieved, the higher the number of wear-resistant, the corresponding cost is higher, and its surface pattern is not clear (coating technology, except for high-definition flooring, such as Kyrgyzstan and other brands)

- Q: How to shop the natural wood flooring

- First keel, in the equipment, with the same solid wood

- Q: Solid wood flooring really okay?

- This kind of floor is very good, but the market is good and bad, or to choose Kaopu, I personally recommend Santa on the floor, they do a good piece of this

- Q: What is the difference between he and solid wood flooring?

- Composite flooring solid wood composite and strengthen the composite points, solid wood composite is the general board, the skin plus a layer of high-end flooring, strengthen the composite floor is the use of wood chips, the surface is made of paper, solid wood is made of pure wood.

- Q: My family is preparing to decorate, is considering the floor or floor tiles, we intend to live with the room with the room is also a rough dwarfed gnome dumplings evil spear pave the floor, but a friend said my house east-west, sunny, afraid of the floor can not stand Alice Is it really like this? There is a large living room area, the floor is assembled. Easy to loose more

- can..........

- Q: How is the maintenance of the new floor laminate?

- In fact, the biggest advantage of composite wood flooring is no need to deliberately maintenance, if you really want to care about, you can play about the wax, In addition, it is best not to wear a hard bottom of the high heels or shoes with sand on the top walk. Of course, can not let your floor blisters. The The

- Q: Nature composite floor quality how?

- Quality does not know, it should be the main solid wood, solid wood composite is relatively small, and one of the samples on the pad putty, then the market is the quality of the natural staff too bad, do not know how the Red Star actually, Service better, the latter part of the problem is also better resolved

- Q: That is clean and easy

- vacuum cleaner

- Q: What is the plastic floor? What is the composite floor?

- Plastic flooring generally refers to PVC flooring, as well as wood flooring. The floor has the material of the material, water resistance, generally suitable for public places. Composite floor, in a broad sense, refers to the structure by the layers of composite floor, such as: laminate flooring, multi-layer parquet, part of the bamboo flooring. As for the floor resistant to burning cigarettes, there are provisions of the national standard. PVC flooring, laminate flooring and other surfaces are often exposed to the end of the seal all over the full set of aluminum oxide wear layer, more resistant to burning, the general bamboo, wood flooring surface is paint,

- Q: Solid wood flooring is not easy to scratches?

- Hard to strengthen the scratch is not easy to strengthen the surface of a layer of chicken feast burning dulcimer tan Mo Mo is very wear-resistant solid wood composite is also very wear-resistant as long as no sharp are not easy to scratch

Send your message to us

Wear-resistant wpc vinyl flooring economical custom design wpc

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m²

- Supply Capability:

- 2000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords