Waterseal Mastic Custom Rubber Vinyl mastic Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description of KC86 Tape

• KC 86 is a self-amalgamating mastic tape used for moisture sealing on all types of telecommunications and solid dielectric power cable splices and connections.

• It is a tacky, temperature stable mastic with excellent conformability and adhesion to metal and all types of cable insulations and jackets.

• It is put up on a white release coat separator in roll form without any core.

• Once applied, KC 86 mastic should be overwrapped with a vinyl or rubber tape which will encapsulate it and, throug centripetal force, make it into every crevice and indentation in a cable jacket thereby giving a superior moisture seal in a splice or aroun any connection.

• The tape is also RoHS compliant, resistant to corrosion, chemicals and salt water and has no adverse effect on cable insulations.

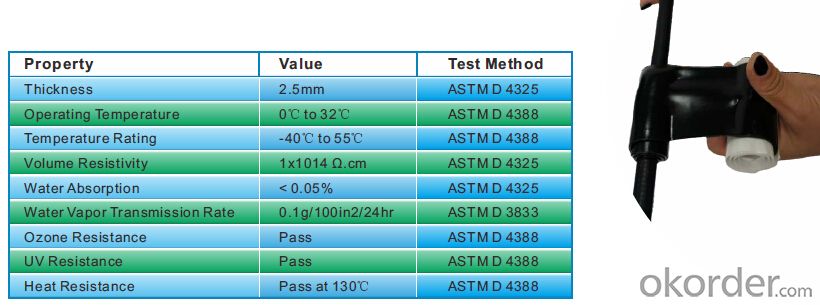

• Its 2.5mm thickness facilitates rapid protection build-up.

• Use in conjunction with KC 63 premium vinyl electrical tape for optimal performance.

Dimensions of KC86 Tape

2.5” x .1” x 23.6”

63mm(width) x 2.5mm(Thickness) x 0.6m(length)

Consult us for other sizes

Specifications of KC86 Tape

Applications of KC86 Tape

• Moisture seal and insulation in power cable through 600 volts

• Moisture seal and insulation of telecommunication cable connections in base stations, antennas and aerial feeders

• Other moisture sealing applications

FAQ

1.Before placing order, can we make sample firstly?

Sample can be arranged to send to you to test before placing order.

Sometimes sample is free ,sometimes sample charge should be included if more than 3 pcs with material .

But we are afraid freight charge will be paid by yourself.

Certainly, we will adjust additional sample and freight charges into your bulk order.

2.How can I get your sample?

Of course, we can send you some samples. Most samples are free, but sometimes we will take small sample fees.

Maybe you also send us your DHL or EMS/UPS/TNT etc account ,so you can pay for air freight to your carrier company directly.

3.Whether we can print our logo or need our color or size or not?

Yes, because we have our own factory and R&D team, so we can make products as your demands.

We can print your logo, we also can make as your size and print it as your color.

4.How many kinds of payment terms you can accept?

About payment terms, we would like 100%TT if less than $1000.00

Usually for bulk order , would like can be paid pay 30%- 50% advanced payment and the rest should be paid before dispatch.

We hope this information will be helpful to you, if you have any question, please feel free to contact us, we are always at your service.

- Q: Bathroom first leveling or do waterproof, what is the difference

- 3. Protective layer with cement mortar smooth. 4. backfill recommended the best use of ceramic, followed by light brick, commonly used slag, can also be overhead, cinder can also be less. Backfill attention to the protection of finished products.

- Q: Slope roof drains do not need to be waterproof

- The overall rigid waterproof layer is often due to these small structural nodes handled properly, resulting in the failure of the entire roof waterproof.

- Q: Cabinet is to buy finished products, or directly to the decoration company to do?

- My home decoration cabinets are Haotian decorative package to do, although expensive, but still very worthwhile, all of their wood will be waterproof and moisture, in contact with the wall will do the underground waterproof and moisture, and are on-site cash Now do, timber materials can be seen directly, the amount of glue is not much, less formaldehyde, the latter part of the living is also more comfortable!

- Q: Home improvement waterproofing problem

- 4, through the door stone paving need to do waterproof, you can directly use cf-2000 efficient composite waterproofing agent treatment, can play paste, waterproof two effects. Just on both sides of the door to do the character to strengthen the treatment on the line can be foolproof.

- Q: How do you make waterproofing in the kitchen and bathroom?

- Fatty acid cement mortar waterproofing agent; integrated current domestic and foreign new waterproof material of the latest technology, in the original polymer cement mortar waterproofing agent developed on the basis of raw materials imported from Germany, the higher fatty acid materials, by more than 20 kinds of raw materials by the special complex Chemical reaction of water-based emulsion, a new type of fatty acid cement mortar waterproofing agent.

- Q: Do you use the waterproof material on the building to be harmful to the human body?

- Of course harmful, not just this particle, there are auxiliary materials are also toxic.

- Q: Hello, roof with SBS waterproof material bulk density is how much?

- As the SBS coil finished with pure asphalt is not the same, the coil includes a variety of surface material weight. The following is the different types and different thickness of the SBS coil unit area weight, due to the need to lap and pave the reinforcement layer, calculate the load in the following unit area weight, the general multiplied by 1.2 coefficient.

- Q: Nanning building waterproof material market where

- Nanning this building waterproof coating does not seem to have a special market, waterproof materials like fast ring building materials market, Wan Tai Long have to sell, as well as Mingxiu Road and Mingxiu Road on both sides of the road have a heavy focus on waterproof materials and companies

- Q: Roof leakage, what materials do the best waterproof

- First, the roof leak to find the first leak, looking for the main leak from the roof to the lower to find leakage. The first is to see if there is no cracks in the roof, the original waterproof layer is not aging, the roof of the original SBS waterproofing membrane has no bubbles, there are bubbles to prove that the water has entered the bottom of the waterproof layer, and thus leaking. There is a block on the roof of the gutter is not blocked in the countryside, there are still a large number of tile-roofed house, when the tiles due to damage caused by the roof leakage, as long as the replacement of tiles can be, this step is also known as "

- Q: What are the key points and contents of the quality control of waterproof material?

- 2, ordinary two-component polyurethane: A material is similar to the appearance of edible oil translucent yellowish curing agent from polyether and isocyanic acid by polycondensation of polyurethane prepolymer (about 20,000 yuan / t), B material For the plasticizer, coagulant, fillers and other components of the black liquid (about 3900 yuan / t), after mixing the polyurethane coating is also black. But also because of A, B material of the huge spread so often the following two kinds of fraud: ① with a very cheap black oil (priced at only about 1,200 yuan / t), diluted with xylene after thin coating twice. Cold oil is not easy to dry after the coating, after each coating must be drying a few days, in the winter with roasted, and then do not sprinkle dry powder cement, so a long time paint are dry. ② is often used to expand the proportion of A, B components such as 1: 4-6 (usually 1: 2), but also in the polyurethane mixing process by adding cement powder as a filler, if the stirring is not added xylene diluted Agents and other methods of fraud.

Send your message to us

Waterseal Mastic Custom Rubber Vinyl mastic Tape

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 roll

- Supply Capability:

- 500000 roll/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords