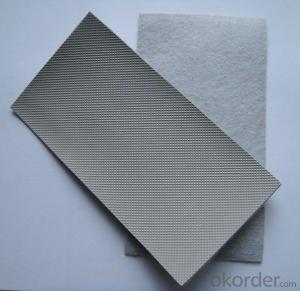

Waterproof Non-woven Aramid Fabric with PTFE Film/Moisture Barrier Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

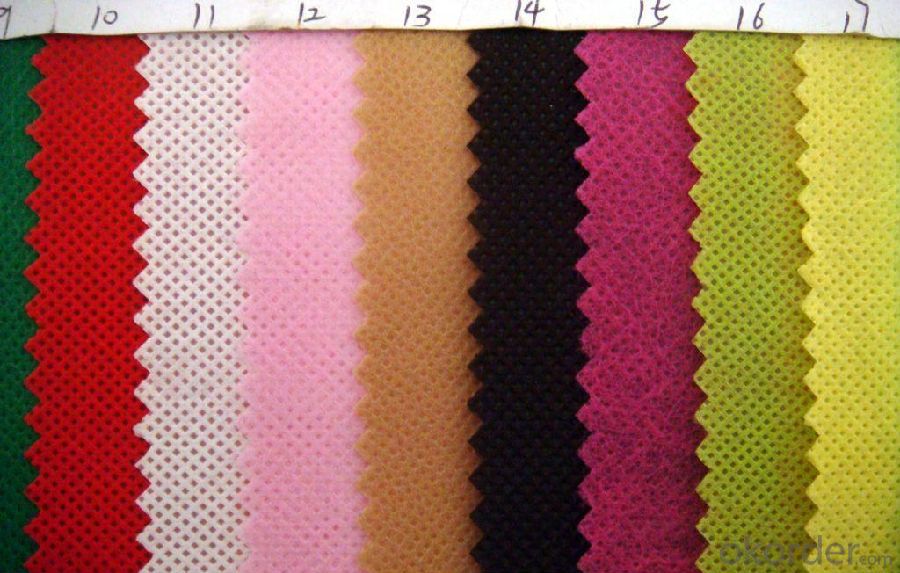

Eco-friendly Polypropylene PET Spunbond Non-woven Fabrics Made in China

Our products have been widely used in the field of medical& sanitary, industry &agriculture, and construction &daily-used products such as agriculture plant covers, roof waterproof materials, disposable items for medical and industrial applications, liners for furniture, lining in cases,apparel, warm facilities, bedding products, sofas, packing materials, packing material land mulriple cloth shopping bags, suits and garment covers, Industrial protective coveralls, garment accessory materials, bed articles, medical and sanitary articles as well.

Our Service:

Within 24 hours reply ;

Well-trained and experienced staffs in English;

OEM & ODM , Customized are warmly welcomed , or design for you ;

Protecting customer’s privacy and profits;

Make sure the quality is approved , or we pay the return or remake them at once .

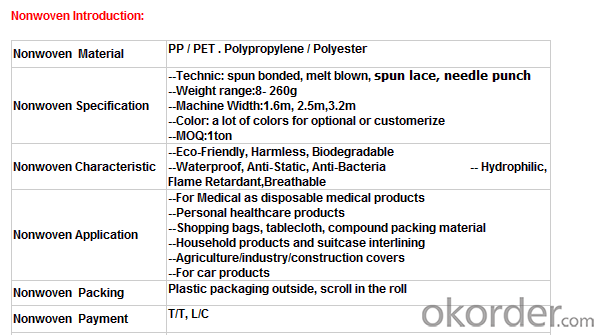

Nonwoven Advantage:

1. Light: Polypropylene is the main raw material; specific gravity is 0.9, is only third five, fleecy and touches well.

2. Flexibility: made up of microfiber (2-3D), dot by dot thermo-melt formed. Flexibility of products is suitable, comfortable.

3. Water resistance and breathability: slices of Polypropylene and finished products resist water, breathable and easy to maintain and wash.

4. Non-toxic, non-irritating: made of materials which catch up FDA standard, without other chemical composition, stable, non-toxic, no smell, safe for sensitive skin.

5. Anti-bacterial, anti-chemical: Polypropylene is blunt chemical substances can protect in liquid from bacterial and insects; antibacterial, alkali corrosion, erosion and the finished product will not affect sensitive skin.

FAQ:

Q: What standards are you carrying out for your products?

A: We produce according to the ISO9001 and ISO14001 rules.

Q: How to install the machine?

A: We will arrange 1~2 engineers to your factory to guide installation and assembly.

Q: What’s your international market?

A: We Have exported to about 40 countries and regions all around the world, such as, the USA, France, Singapore, Australia, Middle East, Brazil, Peru and so on.

Q: Do you sell steel shot or steel grit which can be uses in shot blasting machine?

A: We have four production lines for steel shot and steel grit production, one work shop for steel cut wire shots, and one workshop for stainless steel shot and Aluminium shot and so on.

Q: Do you have the right to export?

A: Yes, we registered in the Customs and gained the right to export by ourselves.

- Q: Listed in recent years the textile industry pollutant emissions

- As the first half of the industrial added value increased by 13.2%, therefore, COD and sulfur dioxide and other major pollutants emissions are still increasing. Structural pollution is still outstanding. In the first half of the year, the COD emissions from the food processing industry, the paper and paper products industry, the chemical raw materials and chemical products manufacturing industry, the textile industry and the chemical fiber manufacturing industry increased by 67% and the growth rate Investigate 82.3% of the total COD emissions of enterprises;

- Q: The problem of anti - splashing of textile fabrics

- Better water repellent treatment is divided by water pressure is not left without traces of the high, if you must leave no trace you can wax

- Q: Textile fabric classification, dyeing and finishing processing is what?

- New type of fabric in the chenille fabric, knitted bamboo fabric should also be classified.

- Q: Classification of antimicrobial textiles and their characteristics

- Natural antimicrobial materials mainly to hemp and chitin-based, which linen products at low prices, the market acceptance is relatively high.

- Q: The international market of textile industry

- Trade protectionism is rampant and trade frictions will intensify. Leading to uncertainties in the trade environment between the trading countries. The textile faces the same mistakes as temporary tariffs and rations. China's exports will also be affected by higher production costs, financing difficulties for export enterprises and rising financing costs, export policy adjustment uncertainty, the impact of RMB appreciation pressure

- Q: What is the specialty of textile science and engineering?

- The research contents of the textile discipline have changed obviously, and the cross and infiltration of the disciplines such as bioengineering, environmental protection engineering and material science engineering have become more and more close.

- Q: What are the knowledge and abilities of the Merchants in the textile industry?

- Therefore, the main content of the work is: to confirm the progress, to help remove the obstacles, requiring quality, verify the number of post-sale problems or transfer to other after-sales department to resolve

- Q: Why can the oil industry be used as raw materials for the textile industry?

- Oil industry, one of the fuel industry. From the exploration, mining to processing a series of oil is completed by the oil sector. For the various sectors of the national economy to provide a variety of fuel oil, including natural oil and oil shale exploration, mining, refining, storage and transportation production units.

- Q: What is the use of polyurethane TPU hot melt adhesives in textiles?

- Lining the general requirements of the hot melt adhesive is colorless and tasteless, soft texture, fast bonding, resistance to dry and wet wash, glue can not affect the fabric, resistant to light and so on. Various types of hot melt adhesives can be used with a wide range of hot melt adhesives. Most of them are ethylene-vinyl acetate (EVA) hot melt adhesives, polyamide hot melt adhesives and high pressure polyethylene (HDPE) heat Melt powder, and different uses of hot melt adhesive and processing methods are also different.

- Q: Why is cotton textiles shrinking?

- The composition of the fabric is fiber, so the fiber will be irreversible after washing wet anisotropy up, resulting in smaller fiber size.

Send your message to us

Waterproof Non-woven Aramid Fabric with PTFE Film/Moisture Barrier Fabric

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches