Quick Details

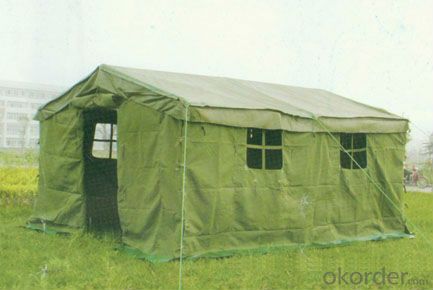

Place of Origin: Shandong, China (Mainland)

Brand Name: Guangji

Model Number: Multiple

product type: 100% polyester

supply type: make-to order

type: tarpaulin

pattern: coated

coated type: HDPE and LDPE coated on both side

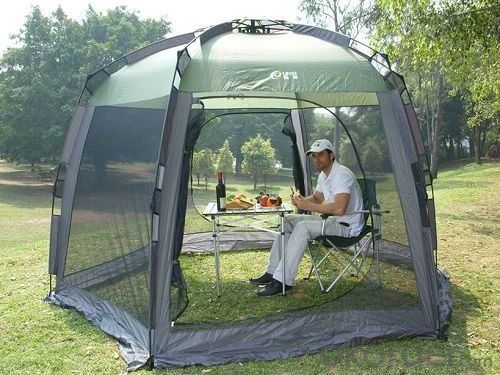

style: tent

width: 2-6m

weight: 100-260gsm

denisty: 8*8,9*9,10*10,11*11,12*12,14*14

techines: woven