Vokes® NPP Fumed Silica Nanoporous Insulation Panel - High Temperature Microporous Insulating Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

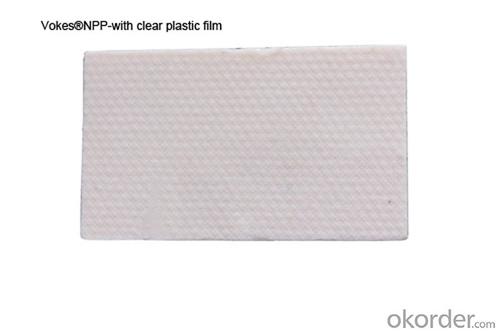

CHARACTERISTICS:

Vokes®NNP is a micro porous thermal insulating panel with excellent insulating properties. The core material of Vokes® NPP is fumed silica which is made by nano technology. Furthermore an infrared opacifier is added to minimize thermal transmission by in heat radiation. It’s noncombustible, specializes in the insulation applications where the space is limited but a high thermal resistance is necessary. Long-term application temperature is during -120℃-1000℃, the insulation performance is much better than the traditional materials, especially at high temperature.

ADVANTAGES:

• Wide insulation range: Long-term working temperature is at the period of -120℃-1000℃.

• Extremely low and stable thermal conductivity: At normal temperature, the insulated performance is at least 3-5 times better than the traditional materials. At temperatures higher than 300℃, the insulated performance is at least 4-8 times better than the traditional materials.

• Space saving: It drastically reduced insulation thickness.

• Easy installation and maintenance: The small density makes installing safely and easily.

•Corrosion resistant: Products are made of inorganic silicates, it doesn’t include soluble chloride ions, won’t cause corrosion on equipments, pipes..

• Soundproof/Shockproof: It helps acoustic noise reduction and shock buffer.

• Waterproof: Nano particles of product themselves are super hydrophobic.

• Durable: It has a long working life.

APPLICATIONS:

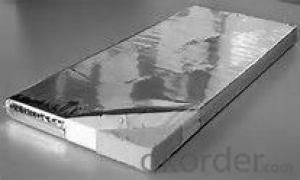

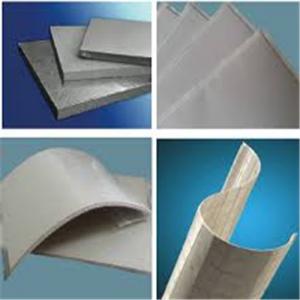

Vokes®NNP is widely used because of the stable thermal performance. According to diverse situations, Vokes®NNP can be protected with appropriate covers.

-Industrial furnace (rotary kiln, shuttle kiln, steel ladle, tundish, oven door etc. )

-Metallurgical industry (steel, aluminum, smelting furnace, holding furnace, etc.)

-Instrument (temperature tracker, heat receiver, date protection system, etc.)

-Oil and energy (piping, reacting furnace, etc.)

-Refrigeration and freezing

-Automotive (Cars, trains, planes, ships, etc.)

PRODUCT DATA:

Surface color: White/Grey

Geometry:Rectangular shape (without protruding flanges*)

Density ≤300kg/m³

Thermal conductivity (Surface temperature:℃)

50℃ 0.016W/(m·k)

200℃ 0.020W/(m·k)

300℃ 0.023W/(m·k)

400℃ 0.025W/(m·k)

500℃ 0.033W/(m·k)

600℃ 0.040W/(m·k)

700℃ 0.049W/(m·k)

800℃ 0.060W/(m·k)

900℃ 0.064W/(m·k)

1000℃ 0.073W/(m·k)

Refractoriness: 1300℃

Cold Crushing Strength (Compression 20%) ≥0.40MPa

Permanent Linear Change(800℃×24h) ≤1.0%

Standard dimension (L x W)(mm): 1200x600/500x600/250x600

Thickness:10mm/15mm/20mm/25mm/30mm/40mm/50mm

Size tolerance • 0 to 500 mm: ±2 mm

Thickness tolerance: ± 1 mm

Service life : extrapolated, depending on application up to 50 years.

- Q: Can insulating fire bricks be used in residential applications?

- Yes, insulating fire bricks can be used in residential applications. They are commonly used in residential fireplaces, wood-burning stoves, and pizza ovens to provide insulation and increase energy efficiency. Their high heat resistance and insulating properties make them suitable for these applications.

- Q: Can insulating fire bricks be used for insulation in incinerators?

- Yes, insulating fire bricks can be used for insulation in incinerators. Insulating fire bricks are made from lightweight refractory materials and have high insulating properties, making them ideal for applications that require heat containment and energy efficiency, such as incinerators. These bricks have low thermal conductivity, which means they can effectively trap and retain heat within the incinerator, preventing it from escaping and improving the overall efficiency of the incineration process. Additionally, insulating fire bricks are resistant to high temperatures and can withstand the harsh conditions typically found in incinerators, making them a reliable choice for insulation purposes.

- Q: Are insulating fire bricks resistant to flame impingement?

- Yes, insulating fire bricks are resistant to flame impingement.

- Q: Can insulating fire bricks be used for flooring insulation?

- No, insulating fire bricks are not suitable for flooring insulation as they are primarily designed for use in high-temperature applications like fireplaces, furnaces, and kilns. Flooring insulation requires materials that can withstand foot traffic, moisture, and other stresses that insulating fire bricks may not be able to handle effectively.

- Q: How do insulating fire bricks affect the overall noise insulation of a building?

- Insulating fire bricks can significantly enhance the noise insulation of a building. These bricks have excellent sound-absorbing properties due to their high density and ability to dampen sound vibrations. By reducing the transmission of airborne and impact noises, insulating fire bricks help create a quieter and more peaceful indoor environment.

- Q: Is it necessary to use mortar when installing insulating fire bricks?

- Using mortar during the installation of insulating fire bricks is necessary. It plays a crucial role in bonding the bricks together, guaranteeing a tight and secure fit. Moreover, it contributes to the creation of a sturdy and long-lasting structure capable of enduring high temperatures. Should mortar be absent, the bricks might not be adequately secured and could shift or loosen, thereby compromising the integrity of the installation. Additionally, mortar serves to fill any gaps or spaces between the bricks, providing insulation and preventing heat loss. Consequently, employing mortar is indispensable for a prosperous and efficient installation of insulating fire bricks.

- Q: Are insulating fire bricks suitable for use in carbon black furnaces?

- Insulating fire bricks, made from refractory materials with excellent insulation properties, are well-suited for carbon black furnaces. These furnaces, operating at temperatures exceeding 1,000 degrees Celsius, benefit from the use of insulating fire bricks by reducing heat loss and improving energy efficiency. The bricks' thermal shock resistance is crucial for the cyclic heating and cooling within the furnace. Furthermore, their low thermal conductivity helps maintain a stable temperature inside the furnace and prevents excessive heat loss. In conclusion, insulating fire bricks provide a dependable and efficient lining option for carbon black furnaces.

- Q: Are insulating fire bricks resistant to hydrofluoric acid?

- Hydrofluoric acid is a highly corrosive substance capable of attacking and dissolving various materials, including fire bricks, which lack resistance to it. Therefore, it is crucial to exercise utmost caution and employ suitable protective gear while dealing with this hazardous substance.

- Q: Are insulating fire bricks porous?

- Indeed, porousness is inherent to insulating fire bricks. It is this attribute that enables them to exhibit low thermal conductivity. Comprised of ceramic materials, these bricks possess a considerable amount of minuscule air pockets or empty spaces. These cavities serve to capture and decelerate the flow of heat. Furthermore, this porosity renders the bricks lightweight and resilient against thermal shock. The efficacy of these insulating fire bricks in retaining heat and furnishing efficient insulation is unequivocally tied to their porous configuration.

- Q: Are insulating fire bricks suitable for use in steel manufacturing plants?

- Yes, insulating fire bricks are suitable for use in steel manufacturing plants. Insulating fire bricks have excellent thermal properties, including high heat resistance and low thermal conductivity, which make them ideal for use in high-temperature environments such as steel manufacturing plants. These bricks can withstand the extreme heat generated during steel production processes, such as melting, casting, and forging. Additionally, insulating fire bricks help to conserve energy by reducing heat loss, thus improving the overall efficiency of the plant. They also have good mechanical strength and can withstand the physical stresses and strains associated with steel manufacturing operations. Overall, the use of insulating fire bricks in steel manufacturing plants can help to enhance safety, increase productivity, and improve energy efficiency.

Send your message to us

Vokes® NPP Fumed Silica Nanoporous Insulation Panel - High Temperature Microporous Insulating Fire Brick

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords