Vokes® NPP (Nanoporous insulation panels)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Vokes® NPP (Nanoporous insulation panels)

Characteristics

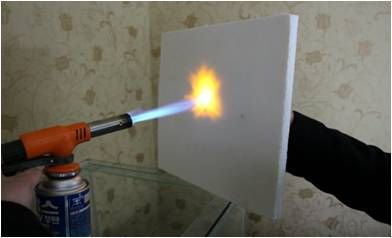

Vokes® NPP is an evacuated micro porous thermal

insulating panel with excellent insulating properties.

Vokes® NPP

The core material of

Vokes® NPP is fumed Silica board and noncombustible.

It is sealed into a high gas barrier film under vacuum.

Vokes® NPP

Application

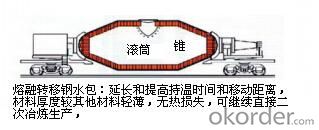

Vokes® NPP is specially developed for insulation

applications where not much space is available but a

high thermal resistance is necessary. Mainly used in

high-temperature insulationMainly used in hightemperature

insulation.

Vokes® NPP

Vokes® NPP is a successful insulation element in the following areas:

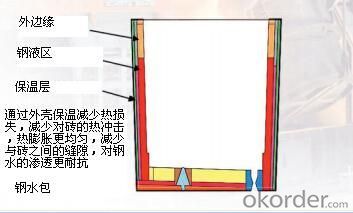

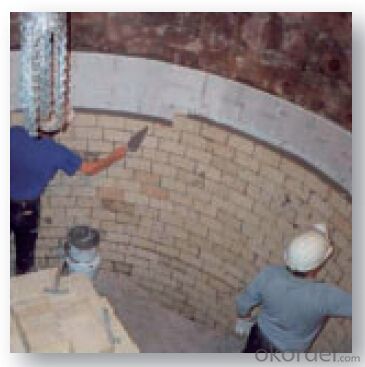

• Industrial equipment insulation

• High temperature boiler insulation

• Thermal packaging (Medicine transport boxes, etc.)

• Appliance (Water boiler, etc.)

• Automotive (train, ship, air plains, etc.)

Advantage

• Insulation : Long-term application temperature reached -120℃-1200℃. Insulation at normal

temperature for 3-5 times the performance of traditional materials. Stable thermal conductivity at high

temperatures, Temperature at 300 ℃ insulation performance is 4-8 times that of traditional materials.

• Drastically reduced insulation thickness

• Thermal resistance :Particles constituting unit having a three-dimensional network structure,

will form many nanoporosity avoid sintering deformation.

• All purpose VIP with a long service life

•Corrosion resistant :Products made of an inorganic material, no soluble chloride ions, No

corrosion on equipment, pipe grassroots.

• Soundproofing/Seismic Performance :Acoustic noise reduction, buffer shock.

• Waterproof :Product nanoparticles themselves with super hydrophobic properties.

Product data

Surface color whiter

Geometry

Rectangular shape (without protruding

flanges*)

Density ≤300kg/m³

Thermal conductivity (Surface

temperature:℃)

50 0.016W/(m·k)

200 0.020W/(m·k)

300 0.023W/(m·k)

400 0.025W/(m·k)

500 0.033W/(m·k)

600 0.040W/(m·k)

700 0.050W/(m·k)

800 0.060W/(m·k)

Refractoriness >1200℃

cold crushing strength

(Compression 20%) ≥0.40MPa

permanent change in dimension on heating

(800℃×24h) ≤1.0%

Standard dimension (L x W)(mm) 250x600/500x600/1200x600

Thickness

10mm/15 mm/20

mm/25mm/30mm/40mm/50mm

Size tolerance

• 0 to 500 mm ±2 mm

Thickness tolerance ± 1 mm

Service life : extrapolated, depending on application up to 50.

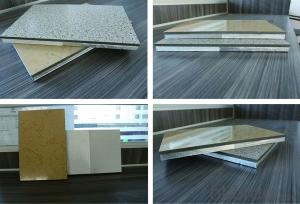

Vokes® NPP Nanoporous insulation panel for industrial applications

Vokes® NPP surface can be a composite various materials(Heat shrinkable film, Glass fiber cloth,

- Q: What is the fan

- Ventilators are widely used for ventilation, dust and cooling in factories, mines, tunnels, cooling towers, vehicles, ships and buildings; ventilation and induced winds for boilers and industrial furnaces; air conditioning and household appliances cooling and

- Q: What material is used for the fan

- Gas compression and gas transport machinery is the conversion of mechanical energy into gas pressure energy and kinetic energy, and the gas transported out of the machinery.

- Q: What is the difference between the function of the feed pump and the condensate pump?

- The condensate pump is used to heat the condensed condensate in the hot water of the condenser into the deaerator by means of a low pressure heater (not high). Deaerator in the deaerator is heated to about 104 degrees Celsius.

- Q: What is the difference between a centrifugal fan and a blower?

- Centrifugal fan: is based on the principle of kinetic energy conversion to potential energy, the use of high-speed rotation of the impeller will accelerate the gas, and then slow down, change the flow, so that kinetic energy into potential energy (pressure).

- Q: The role of the blower in the sewage treatment plant

- The blower is eccentric to the rotor biased in the cylinder and causes the volume change between the blades in the rotor slot to suck, compress and vent the air.

- Q: Fan and compressor similarities and differences

- The former is often called turbine or axial turbine compressor, which is often called centrifugal air compressor.

- Q: How much the blower power is

- 3. Fan motor power and air volume, wind pressure hook.

- Q: What is the water pump

- Motor use AC motor, so the pump speed is fixed speed, boiler water regulation through the "throttling" adjustment.

- Q: What is the difference between a high-pressure ring fan and a Roots blower?

- When the impeller rotates, due to the role of centrifugal force, the wind vane to promote the forward and outward movement of gas, thus forming a series of spiral movement.

- Q: Usually the fan can be divided into several types

- Fans can be divided according to the use of material classification, such as iron fan (ordinary fan), glass steel fan, plastic fan, aluminum fan, stainless steel fan, etc.

Send your message to us

Vokes® NPP (Nanoporous insulation panels)

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords