UPVC Pipe And CPVC Solid Pipe Plastic Extruder Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

Our pipe extrusion line can be used to produce PVC, HDPE, and HDPP pipes with the diameter between 12mm and 400mm. The well-coordinated components, coupled with auxiliary machines, allow this pipe production line to produce pipes for different purposes, including drain pipes, water supply pipes, electrical conduits, PVC fire-retardant pipes, as well as piping for use in chemical industry.

Working flow:

Mixer→ Vacuum feeding →Material dry → Single screw extruder →Marking line extruder(co-extrusion)→Vacuum calibration spraying cooling tank → Spraying cooling tank→ Color-ribbon printer → Haul-off machine →Cutter →Stacker

Packaging & Delivery

| Packaging Detail: | plastic film package or according to customers' demand |

| Delivery Detail: | 30 days after receiving 30% advanced payment |

Specifications

1.Easy to operation and running steadily

2.Good after-service

3.Preferential price

4.Advanced Design

Main charaters:

This line can solve the problems of high temperature melting, high viscosity, easy-decomposition. The

special designed screw, gearbox, tooling, and HMI system make the line reliable and easy operation.

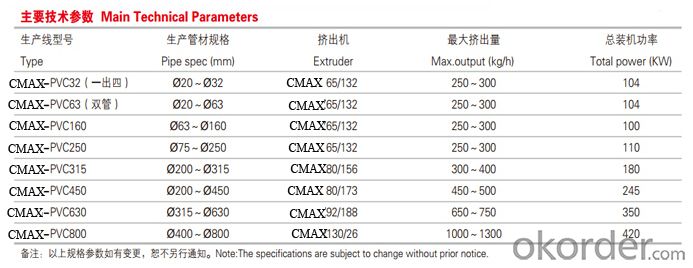

Main Technical Parameters

If you are interested in our product, please be free to contact us.Whether we could cooperate, we would do our best to help you. I’m confident that will be benefit to you and us!

FAQ:

1). What kinds of plastic machinery do you need ? Or what material do you want to process?

2). What capacity do you want? (kg/h )

3). What is the max and min size of the finish products .For example, the diameter of pipe(inch or mm); thickness of pipe wall(mm); width and thickness of sheet (mm)? If profile product, you’d better offer the picture of sample or drawing of sample.

4) What is the electric device you need ? Siemens, Omron or domestic ?

5) When do you want the machine? (Times for delivery)

6) Other requirements about the machine you want.

- Q: Basic parameters of extruder screw

- 3, compression ratio epsilon, also known as the geometric compression ratio of screw, is the ratio of the volume of the first screw groove to the volume of the last screw groove at the homogenization section. It is determined by the physical compression ratio of plastics - that is, the density of the product and the density of the performance of the feed. The extruder is relatively compressed, the purpose is to make granular plastics fully plasticized and compacted. The selection of compression ratio should be different when different kinds of processing plastics are used. According to the compression ratio, the types of screw can be divided into three types: equidistant, unequal depth, equal depth, unequal distance, unequal depth, unequal distance. Among them, equidistant and unequal depth is the most common one. This kind of screw is easy to process, the contact area of plastic and cylinder is large, and the effect of heat transfer is good.

- Q: Why do screw extruders often extrude light red plastic products?

- You should have before the production of red raw material hopper or hopper and barrel, or between the screw shank and barrel etc. the raw material residue, not clean, often with extrusion part. Cause this situation. Please clean the hopper thoroughly. The screw is also drawn out and cleaned up. It should be easy to solve.

- Q: What is the temperature setting of the extruder and how much is the setting temperature of the head and filter?,

- The temperature setting of the extruder is related to the material you manufacture. If the type of plastic is different, the setting temperature is different, and the material of different manufacturers is also slightly different from the temperature setting.

- Q: Why single screw extruder is controlled by high school and low?

- I feel like I didn't explain the problem

- Q: Before and after the original good tune, up and down again before and after the tune, before and after, and up and down again

- The nose is not accurate enough or wornOr the screws are not screwed in placeOr die inappropriate, too large

- Q: Taper twin screw extrusion machining of plastic masterbatch? What ancillary equipment do you need?

- because itself is not suitable for the design of double cone, adjustment of the formula is the key.

- Q: Wire and cable extrusion machine extrusion die how to quickly adjust the core degree, how can I touch it by hand?,

- In fact, if you are familiar with that extruder, there will be no problem!

- Q: The working principle of an extruder

- What is the working principle of an extruder?:Screw with specific shape,Turn in a heated barrel,It will be delivered from the hopperThe plastic is pressed forward, allowing the plastics to be uniformly plasticized (i.e., melted)Through the head and different shapes of the mold, the plastic extrusionA continuous plastic layer of various shapes, extruded on the core and cable.

- Q: Who knows the temperature regulation method of the extruder?Any information will do

- 1, extrusion methodAccording to plasticizing methods: dry extrusion and wet extrusionPress the way: continuous extrusion and intermittent extrusion2, characteristicsContinuous production, high efficiency, simple operation, wide range of applications [Edit] paragraph extrusion molding equipment 1, the hostExtrusion system: composed of screw and barrel, it is the key part of extruder. Its function is to melt plastics, quantitative, constant pressure, constant temperature extrusion of meltDrive system: drive the screw to increase the required torque and torqueHeating and cooling system: guarantee the temperature of plastic and extrusion system in molding process2 auxiliariesIt is composed of head, setting device, cooling device, traction device, coiling device and cutting3 、 control systemIt consists of electric apparatus, instrument and actuating mechanismPurpose: to control the main and auxiliary motor, in order to meet the demands of speed and power; control main engine temperature and pressure and flow, to ensure product quality; to achieve automatic control of the extrusion unit, ensure the coordinated operation of main and auxiliary equipment. [edit this paragraph] extruder extruder overview of plastic extruder is the host, it consists of extrusion system, transmission system and the heating and cooling system.

- Q: Does anyone know the operating procedures for the cable 65+120 extruder?

- Operating procedures are based on the preparation of equipment instructions, you can increase some of the preparatory work before the boot, the middle is the operation of equipment instructions, and finally must have safe and civilized operation instructions!

Send your message to us

UPVC Pipe And CPVC Solid Pipe Plastic Extruder Line

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 set

- Supply Capability:

- 30 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords